A belt type sintering machine ignition device

The technology of a belt sintering machine and an ignition device is applied in the field of ignition device and belt sintering machine ignition device, which can solve the problem that it is difficult to achieve uniform ignition temperature of the sintering machine, and achieves good ignition effect, short ignition time and low fuel consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

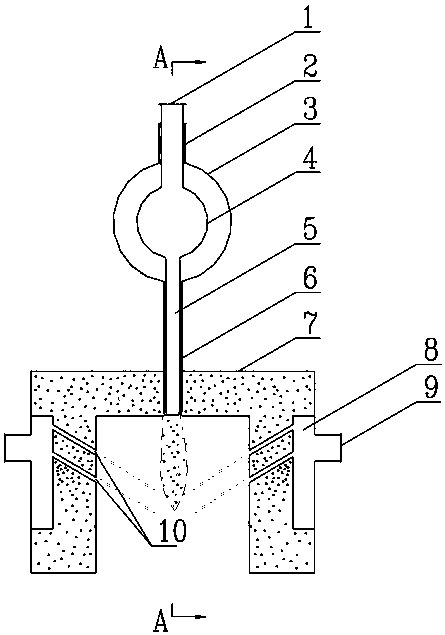

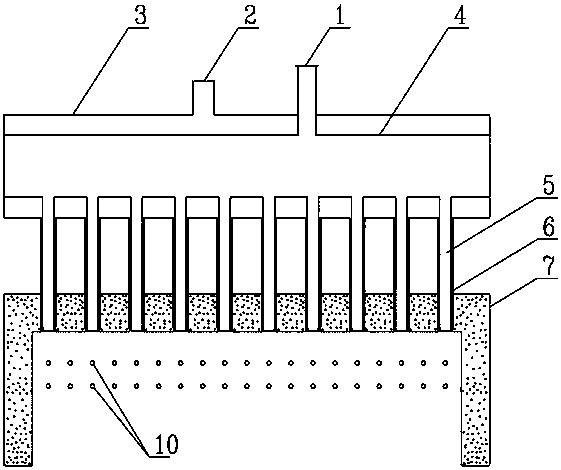

[0027] in accordance with figure 1 The specific implementation of the ignition device of the lead-zinc material sintering belt sintering machine of the present invention will be described below.

[0028] A belt type sintering machine ignition device, such as figure 1 As shown, it is mainly composed of a fuel distribution chamber, a primary air distribution chamber, a fuel ejection branch pipe, a primary air ejection branch pipe, a secondary air distribution chamber, a secondary air ejection channel, a combustion chamber, and the like. The fuel distribution chamber is made of seamless steel pipes and is connected with a fuel inlet and multiple fuel ejection branches. The fuel distribution chamber is sheathed in the primary air distribution chamber. The primary air distribution chamber is made of seamless steel pipes, connected with one primary air inlet, multiple (the same number of fuel ejection branch pipes) primary air ejection branch pipes, and the primary air ejection branch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com