Self-stable combustion low-cost W flame boiler micro-oil ignition device

A low-cost technology for micro-oil ignition, which is applied to combustion ignition, igniters with fuel, burners, etc., can solve the problems of large wear and tear of micro-oil guns, cost of micro-oil ignition transformation and high equipment maintenance costs, and saves equipment. Cost, good ignition effect, low retrofit cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be further described below in conjunction with the drawings.

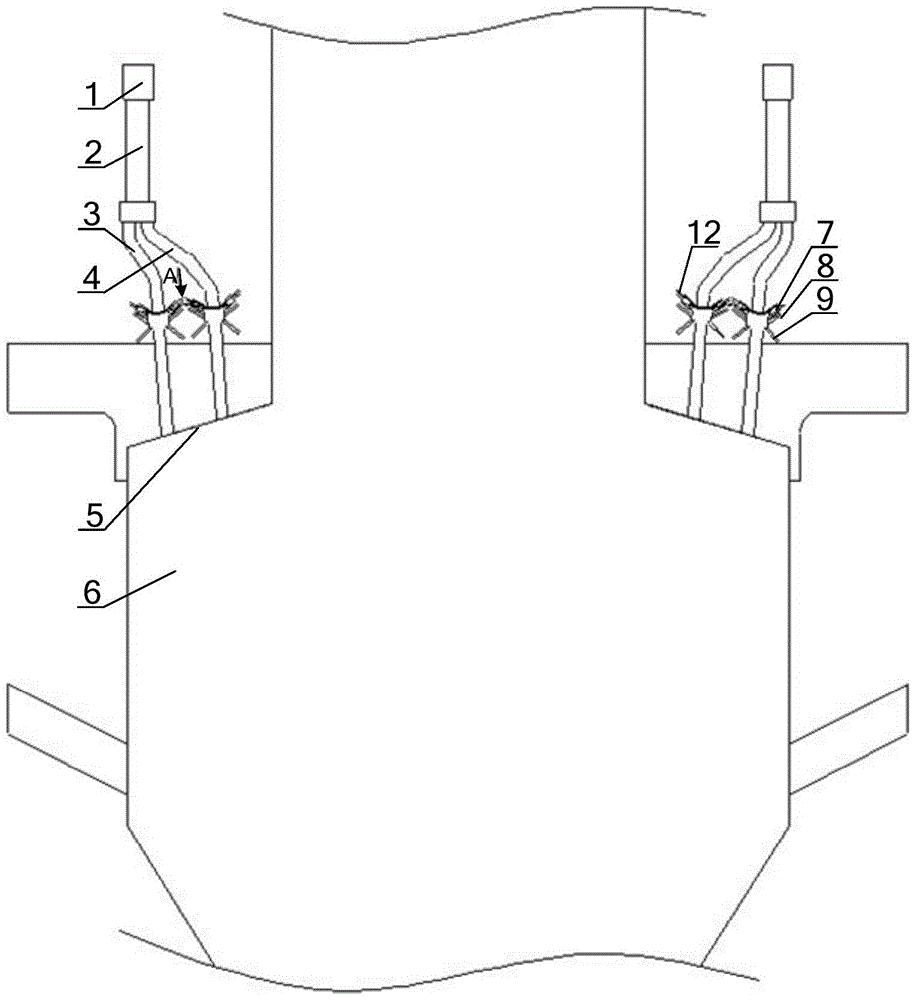

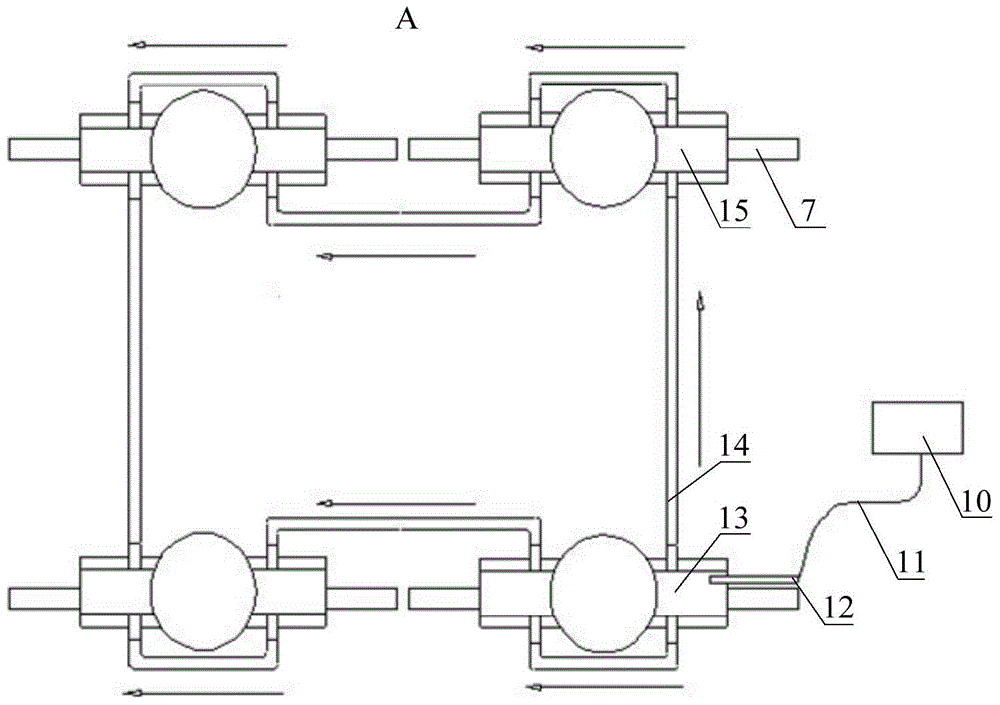

[0018] See attached figure 1 And figure 2 , The self-stabilized combustion low-cost W flame boiler micro-oil ignition device of the present invention includes a micro-oil gun, a fire detector 9, a high-energy igniter 10, an ignition cable 11 and an ignition rod 12; each concentrated coal pulverized coal pipeline 4 and each light coal The powder pipes 3 are respectively symmetrically arranged with micro-oil guns, which include a main oil gun 7 and an auxiliary oil gun 8. The combustion chamber 15 of each main oil gun 7 is connected with the combustion chamber 15 of the adjacent main oil gun 7 The tube 14 communicates with the combustion chamber 15 of any one of the main oil guns 7 as the main combustion chamber 13. The main combustion chamber 13 is provided with an ignition rod 12, and the ignition rod 12 is connected to the high-energy igniter 10 through an ignitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com