Microfluidization cold-state ignition starting method for circulating fluidized bed boiler

A circulating fluidized bed, ignition start-up technology, which is applied to fluidized bed combustion equipment, combustion methods, fuels burned in a molten state, etc., can solve the problems of large bed temperature deviation, long start-up time, and slow temperature rise of bed materials. Achieve the effects of short ignition time, low starting fuel consumption and low inlet oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

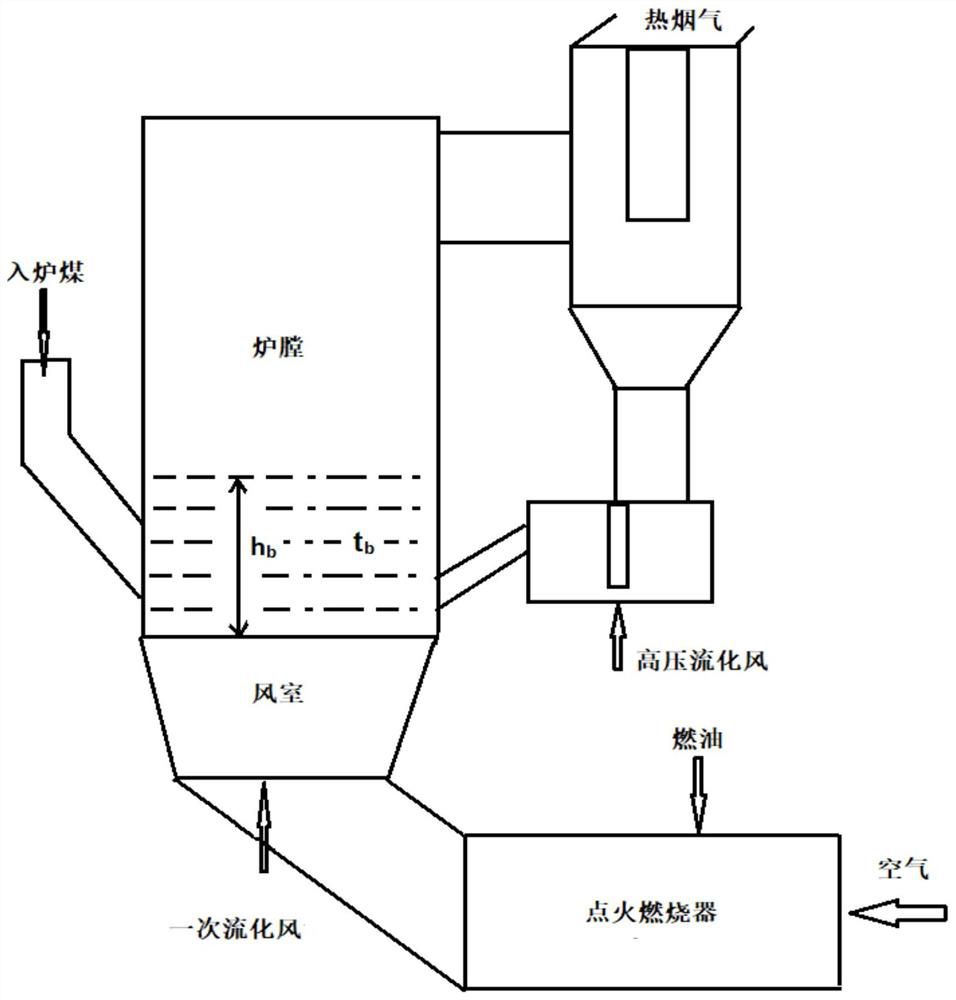

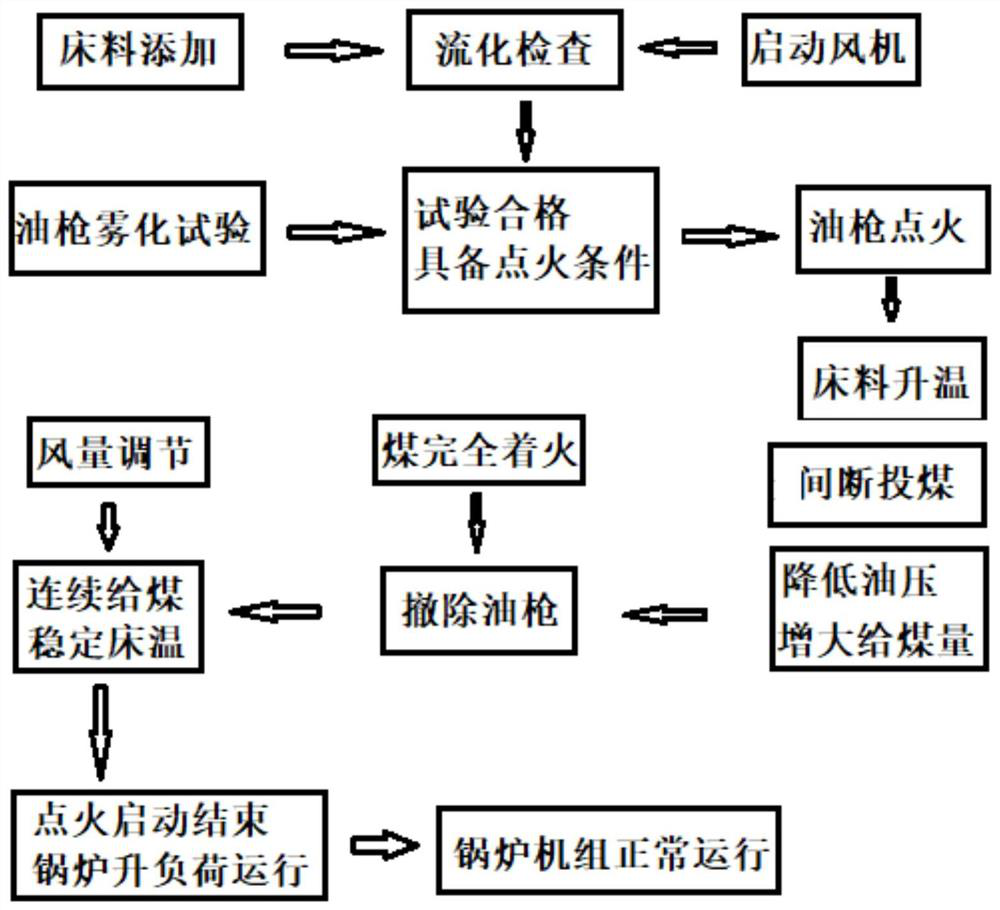

[0031] In this embodiment, a microfluidization cold-state ignition start-up method for a circulating fluidized bed boiler is specifically provided. , particle size distribution, coal feeding method and other aspects, optimize the design of fluidization state, combustion concept and new operation control mode of boiler cold ignition start, which can well solve the problems existing in the original ignition start method and effectively avoid boiler ignition Operation accidents such as coking in the furnace, damage to the ignition burner, and deformation of the heating surface during the process greatly improve the safety and economical efficiency of the cold ignition start-up of the circulating fluidized bed boiler.

[0032] Specifically, the startup method includes:

[0033] S1: Test whether the ignition conditions are met, if yes, go to the next step; if not, return to debugging; among them, the judgment of whether the ignition conditions are met is as follows:

[0034] It is...

Embodiment 2

[0049] Taking the treatment of a 330MW subcritical circulating fluidized bed boiler in China as an example for the "coking accident at ignition start-up", after the efficiency improvement of the boiler, during the first cold ignition start-up process, the bed temperature deviation was large and the temperature rise was slow, and the operating personnel Increase the fluidization air volume and increase the inlet oil pressure, and the bed temperature rises slowly. After a long period of time, the bed temperature reaches the coal feeding condition, and the coal feeding starts intermittently. Due to the mismatch between the combustion air volume and the coal feeding volume, the coal in the furnace does not completely ignite and burn. , causing a large amount of unburned carbon to accumulate in the furnace. As the bed temperature rises, the unburned carbon in the furnace, the coal fired into the furnace, and the fuel oil burn together, resulting in a rapid rise in the bed temperature...

Embodiment 3

[0052] Take a 350MW supercritical circulating fluidized bed boiler in China as an example. During the cold ignition start-up process of the boiler during the trial operation stage, the bed temperature difference between the front wall and the back wall of the furnace is extremely large (>300°C), the bed temperature rises very slowly, the primary fluidization air volume is large (completely fluidized state), and the fuel oil The pressure (3.2MPa) is high, the output of the oil gun is large (6-7t / h), and the bed temperature is difficult to reach the coal injection temperature. It is difficult to inject coal into the guide, and the oil gun cannot be removed for a long time, resulting in a particularly long time for the entire ignition process ( 6~7h), the oil gun is very high (>80t).

[0053] The power plant began to think that there was a problem with the boiler design. Through cause analysis and technical exchanges, it was suggested that the power plant adopt the ignition start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com