Deflagration bomb and preparation method thereof

A technology of igniting powder and powder column, which is applied in the direction of offensive equipment, weapon accessories, blasting barrels, etc., can solve the problems of not being able to destroy unexploded bombs quickly, safely and efficiently, and achieve good fluidity, high ejection speed, and increased Effect of spray distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

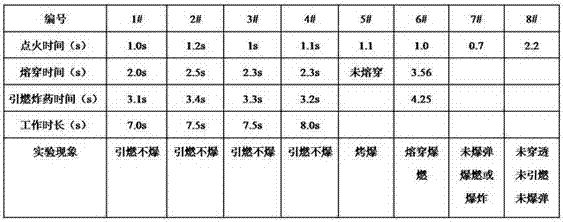

[0046] Embodiment 1: ignite and destroy the bomb.

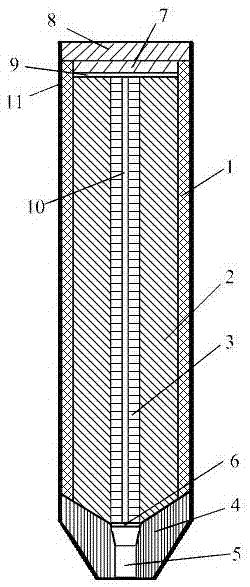

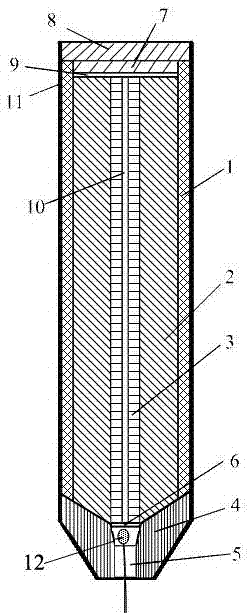

[0047] Such as figure 1 As shown, the destruction bomb of the present invention is mainly composed of outer shell 11, inner shell 1, main charge grain column 2, ignition grain grain column 3, cover and nozzle 4 and other parts.

[0048] The inner casing 1 is a cylindrical tube made of kraft paper, with a length of 60-120mm, an inner diameter of 24-38mm, and a thickness of 2-2.5mm, and is used to protect the grain inside it.

[0049] The outer casing 11 is a steel pipe body with a thickness of 0.5-1mm, including an upper cylindrical part and a lower truncated cone part. The cylindrical part is 10mm longer than the inner casing 1, and the inner diameter is 0.2~0.5mm larger than the inner casing 1, so as to facilitate assembly. The frustum part is 20mm long, and the external cone angle is 60°. ~6mm round hole.

[0050] The main charge powder column 2 is hollow tubular, filled inside the inner casing 1, and can generate metal ...

Embodiment 2

[0055] Embodiment 2: the making of the main charge powder column.

[0056] The main charge powder column of the present embodiment is made of following raw materials:

[0057] Main reaction medicine 68g

[0058] Aluminum oxide powder 5g

[0059] Air-generating agent 5g

[0060] Auxiliary medicine 22g.

[0061] Among them, the main reaction agent is made of 20.4g ferric oxide powder, 34g ferric oxide powder and 13.6g aluminum powder;

[0062] The gas-generating agent is made of 2g of silicon carbide powder and 3g of potassium nitrate powder;

[0063] The auxiliary agent is made of 6g copper oxide powder, 4g aluminum powder, 3g silicon dioxide powder, 5g nickel powder, 2g calcium fluoride powder, and 2g calcium carbonate powder.

[0064] The preparation method of the present embodiment comprises the following steps:

[0065] First, select iron sesquioxide powder, ferric oxide powder, aluminum powder, copper oxide powder, potassium nitrate powder, calcium fluoride powder, s...

Embodiment 3

[0069]Embodiment 3: the making of main charge powder column.

[0070] The main charge powder column of the present embodiment is made of following raw materials:

[0071] Main reaction medicine 60g

[0072] Aluminum oxide 1g

[0073] Air-generating agent 9g

[0074] Auxiliary medicine 30g.

[0075] Wherein, the main reaction agent is made of 21g ferric oxide powder, 24g ferric oxide powder and 15g aluminum powder;

[0076] The gas-generating agent is made of 3g of silicon carbide powder and 6g of potassium nitrate powder;

[0077] The auxiliary agent is made according to 9g copper oxide powder, 6g aluminum powder, 3g silicon dioxide powder, 7.5g nickel powder, and 4.5g calcium carbonate powder.

[0078] The preparation method of this embodiment is the same as embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com