High-voltage instant semiconductor bridge ignition module

A semi-conductor and instantaneous technology, applied in the direction of weapon accessories, fuzes, electric fuzes, etc., can solve the problems of high ignition voltage, reduce ignition voltage and ignition energy, etc., and achieve the effect of low ignition voltage, small size and low ignition energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

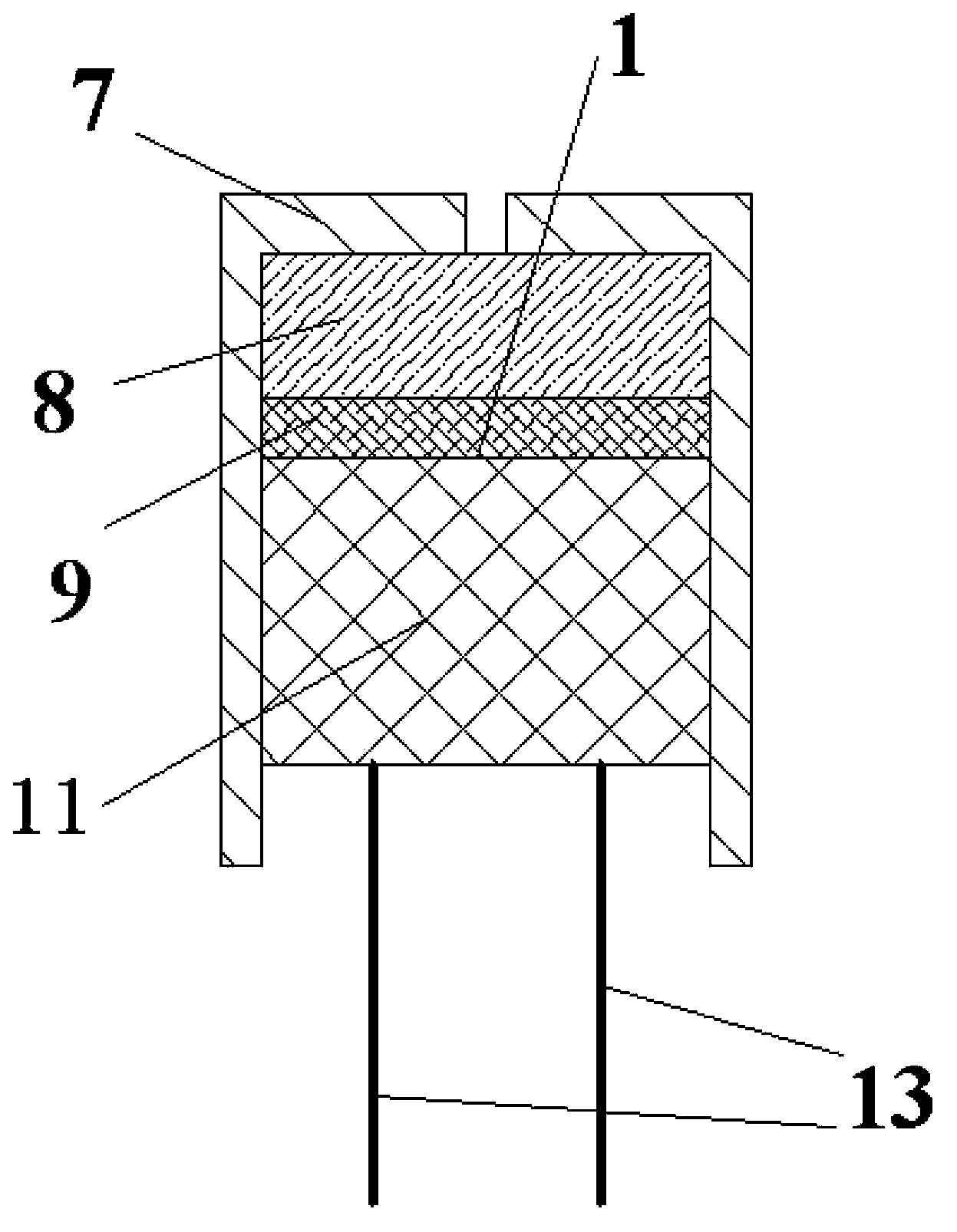

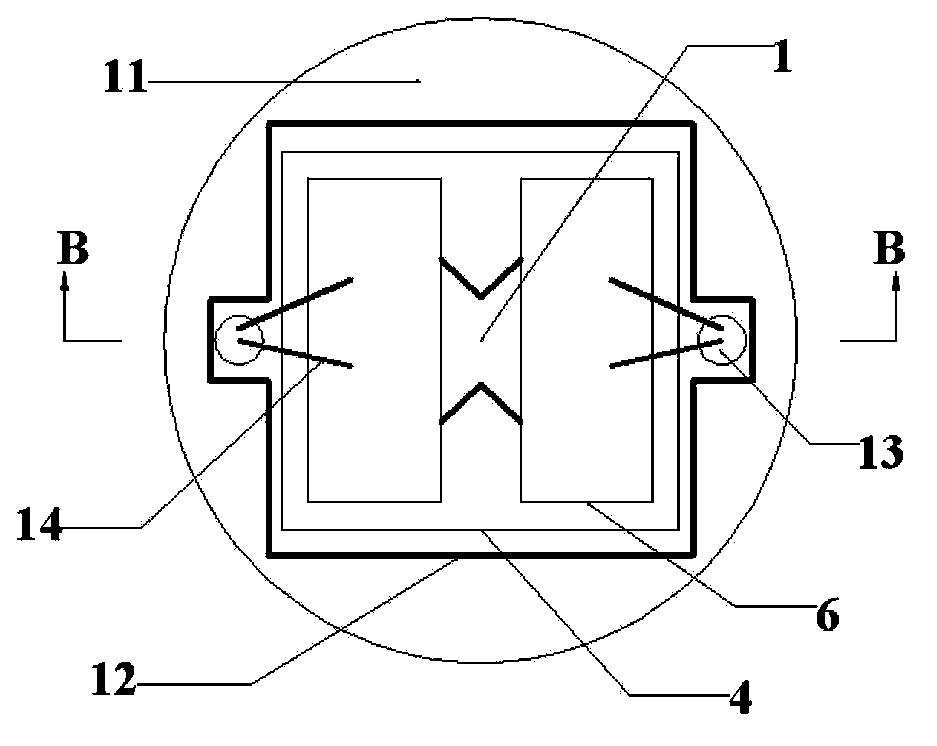

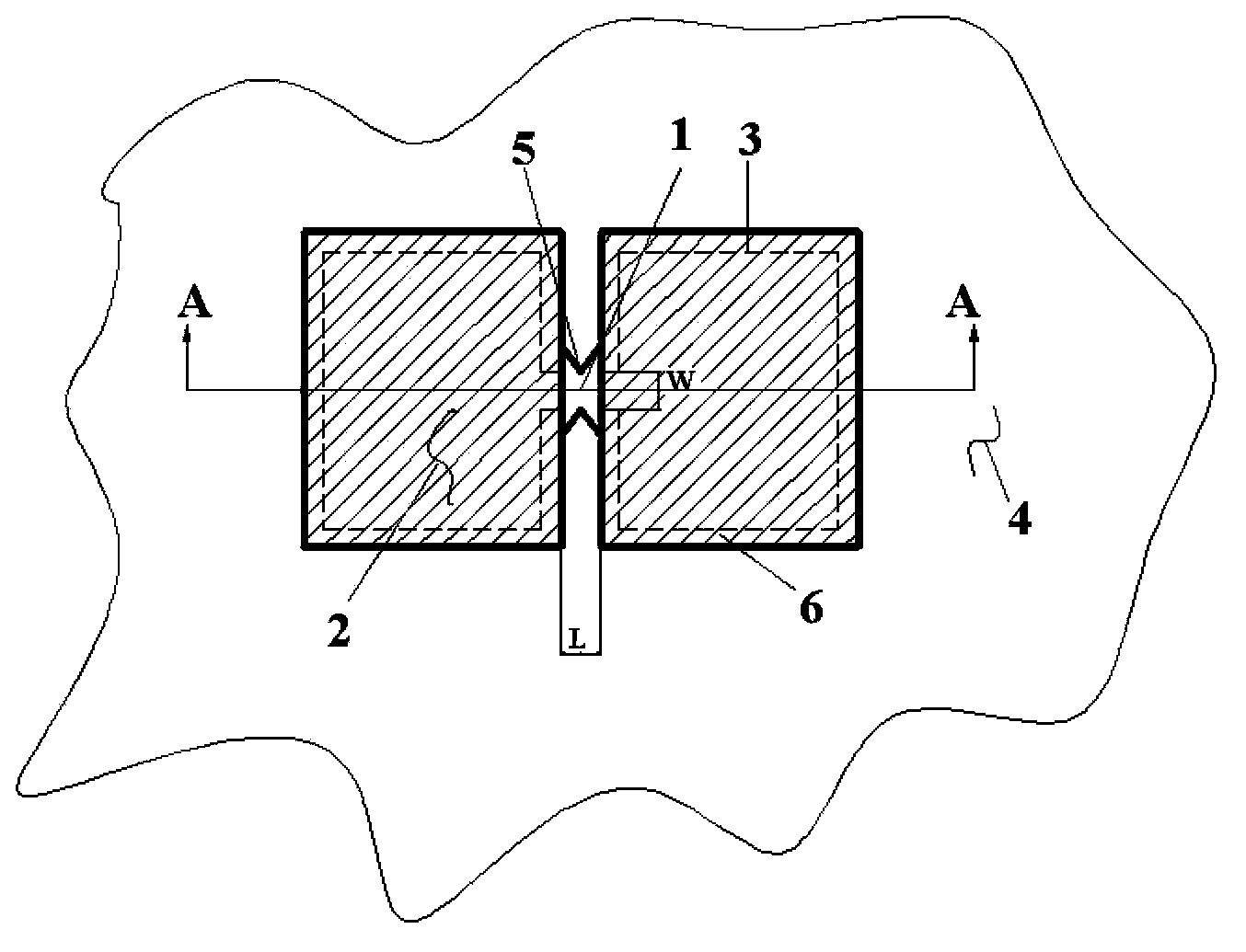

[0030] In order to overcome the shortcoming that the ignition voltage of the existing semiconductor bridge is difficult to drop below 10V when the 10μF capacitor is discharged, the present invention designs a high-instant semiconductor bridge ignition component, whose structure is as follows figure 1 As shown, the ignition voltage can be reduced to below 6.3V by using the present invention, and the ignition time can be reduced to below 10 μs when the discharge voltage is 10V.

[0031] Such as figure 1 As shown, the high-prompt semiconductor bridge ignition assembly of the present invention includes a transducer element, a charge and a shell 7; charge.

[0032] The low-energy burst micro-semiconductor bridge transducer includes a ceramic electrode plug 11 and a semiconductor bridge chip, and the semiconductor bridge chip includes a silicon substrate, a polysilicon su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com