A kind of composite incendiary agent for destroying bombs and its preparation method

A combustion agent and agent technology, applied in blasting, explosives, etc., can solve the problems of large amount of combustion agent and poor penetration ability, and achieve the effects of short ignition time, strong penetration ability and stable ejection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

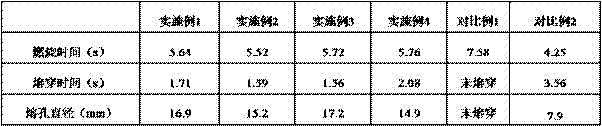

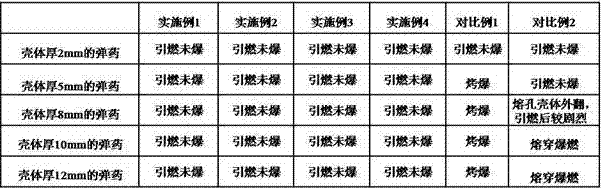

Examples

Embodiment 1

[0026] The composite combustion agent of the present embodiment is made of following raw materials:

[0027] Main reaction medicine 68g

[0028] Aluminum oxide powder 5g

[0029] Air-generating agent 5g

[0030] Auxiliary medicine 22g.

[0031] Among them, the main reaction agent is made of 20.4g ferric oxide powder, 34g ferric oxide powder and 13.6g aluminum powder;

[0032] The gas-generating agent is made of 2g of silicon carbide powder and 3g of potassium nitrate powder;

[0033] The auxiliary agent is made of 6g copper oxide powder, 4g aluminum powder, 3g silicon dioxide powder, 5g nickel powder, 2g calcium fluoride powder, and 2g calcium carbonate powder.

[0034] The preparation method of the present embodiment comprises the following steps:

[0035] First, select iron sesquioxide powder, ferric oxide powder, aluminum powder, copper oxide powder, potassium nitrate powder, calcium fluoride powder, silicon carbide powder with a particle size of 80-100 mesh; Aluminum...

Embodiment 2

[0039] The composite combustion agent of the present embodiment is made of following raw material:

[0040] Main reaction medicine 60g

[0041] Aluminum oxide 1g

[0042] Air-generating agent 9g

[0043] Auxiliary medicine 30g.

[0044] Wherein, the main reaction agent is made of 21g ferric oxide powder, 24g ferric oxide powder and 15g aluminum powder;

[0045] The gas-generating agent is made of 3g of silicon carbide powder and 6g of potassium nitrate powder;

[0046] The auxiliary agent is made according to 9g copper oxide powder, 6g aluminum powder, 3g silicon dioxide powder, 7.5g nickel powder, and 4.5g calcium carbonate powder.

[0047] The preparation method of the present embodiment comprises the following steps:

[0048] First, select iron sesquioxide powder, ferric oxide powder, aluminum powder, copper oxide powder, potassium nitrate powder, calcium fluoride powder, silicon carbide powder with a particle size of 80-100 mesh; Aluminum powder; nickel powder and sili...

Embodiment 3

[0051] The composite combustion agent of the present embodiment is made of following raw material:

[0052] Main reaction medicine 70g

[0053] Aluminum oxide 3g

[0054] Air-generating agent 7g

[0055] Auxiliary medicine 20g.

[0056] Among them, the main reaction agent is made of 15.4g ferric oxide powder, 40.6g ferric oxide powder and 14g aluminum powder;

[0057] The gas-generating agent is made of 3.18g of silicon carbide powder and 3.82g of potassium nitrate powder;

[0058] The auxiliary agent is made of 6g copper oxide powder, 4g aluminum powder, 2g silicon dioxide powder, 5g nickel powder, and 3g calcium fluoride powder.

[0059] The preparation method of the present embodiment comprises the following steps:

[0060] First of all, choose ferric oxide powder, iron oxide powder, aluminum powder, copper oxide powder, potassium nitrate powder, calcium fluoride powder, silicon carbide powder with a particle size of 100~140 mesh; Aluminum powder; nickel powder and si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com