Anti-slagging biomass pellet fuel and preparation method thereof

A biomass particle, slagging technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of difficult to remove, ash accumulation, slagging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

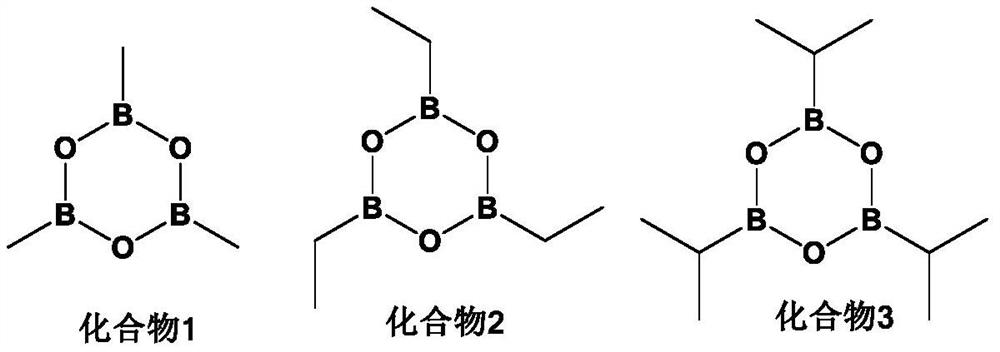

Method used

Image

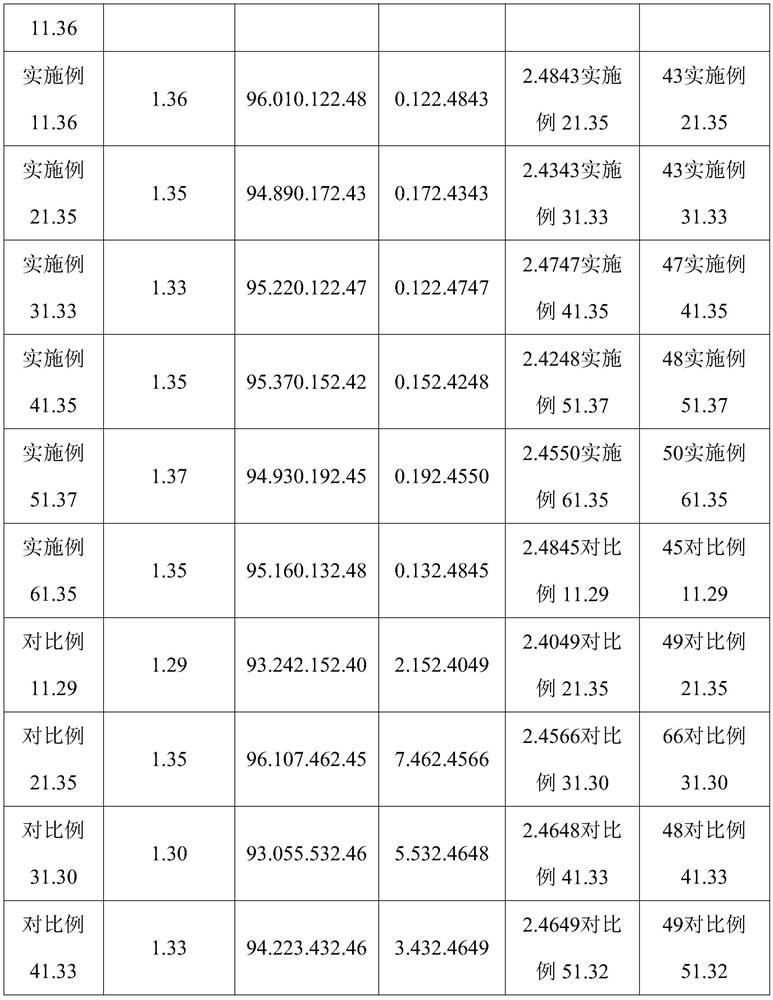

Examples

Embodiment 1

[0037] An anti-slagging biomass granular fuel is prepared from the following raw materials in parts by weight:

[0038] 30 parts of corn stalks, 20 parts of peanut shells, 10 parts of poplar wood chips, 10 parts of activated sludge, 2 parts of fly ash, 2 parts of bacterial stick waste, 1000 parts of dealkalization treatment solution, 0.1 part of hydroxypropyl methylcellulose , 10 parts of modified kaolin, 5 parts of anti-slagging agent.

[0039] Wherein, the preparation method of modified kaolin is as follows:

[0040] Mix kaolin and calcium acetate evenly at a mass ratio of 3-5:1, raise the temperature to 80-100°C and keep it warm for 5-10 hours under nitrogen protection, take it out after cooling to room temperature, add it to water, add microcrystalline paraffin, and stir After forming a paste, let it stand for 1-2 hours, dry at 50-60°C for 10-15 hours, heat up to 130-140°C and calcinate for 30-60 minutes, cool to room temperature and grind through a 200-400 mesh screen. ...

Embodiment 2

[0044] An anti-slagging biomass granular fuel is prepared from the following raw materials in parts by weight:

[0045] 25 parts of corn stalks, 20 parts of peanut shells, 5 parts of poplar wood chips, 10 parts of activated sludge, 1 part of fly ash, 3 parts of bacteria stick waste, 500 parts of dealkalization treatment solution, 0.5 parts of hydroxypropyl methylcellulose , 10 parts of modified kaolin, 5 parts of anti-slagging agent.

[0046] Wherein, the preparation method of modified kaolin is as follows:

[0047] Mix kaolin and calcium acetate evenly at a mass ratio of 5:1, raise the temperature to 80°C and keep it warm for 10 hours under the protection of nitrogen, take it out after cooling to room temperature, add it to water, then add microcrystalline paraffin, stir it into a paste, and let it stand Set for 1h, dry at 50°C for 10h, then heat up to 130°C and calcined for 60min, cool to room temperature and grind through a 200-mesh sieve.

[0048] The preparation method ...

Embodiment 3

[0051] An anti-slagging biomass granular fuel is prepared from the following raw materials in parts by weight:

[0052] 20 parts of corn stalks, 20 parts of peanut shells, 5 parts of poplar wood chips, 10 parts of activated sludge, 1 part of fly ash, 1 part of bacteria stick waste residue, 500 parts of dealkalization treatment solution, 0.1 part of hydroxypropyl methylcellulose , 5 parts of modified kaolin, 5 parts of anti-slagging agent.

[0053] Wherein, the preparation method of modified kaolin is as follows:

[0054] Mix kaolin and calcium acetate evenly at a mass ratio of 3:1, raise the temperature to 80°C and keep it warm for 5 hours under the protection of nitrogen, take it out after cooling to room temperature, add it to water, then add microcrystalline paraffin, stir it into a paste, and let it stand Set for 1h, dry at 50-℃ for 10h, then heat up to 130℃ and calcined for 30min, cool to room temperature and grind through a 200-mesh sieve.

[0055] The preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com