Small-size quickly separated firer-unlocking bolt

A technology for unlocking bolts and pyrotechnics, applied in the direction of screws, weapon types, threaded fasteners, etc., can solve the problems of increased power supply size, difficulty in supplying current and load, and increased power supply load, achieving small structure size and synchronization. High, short separation time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

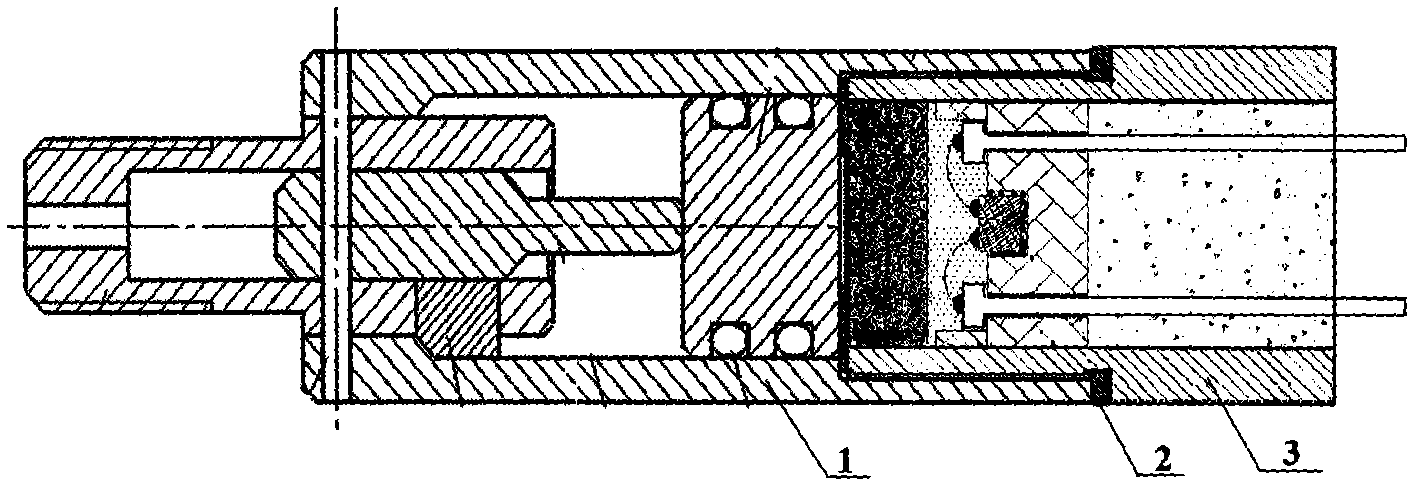

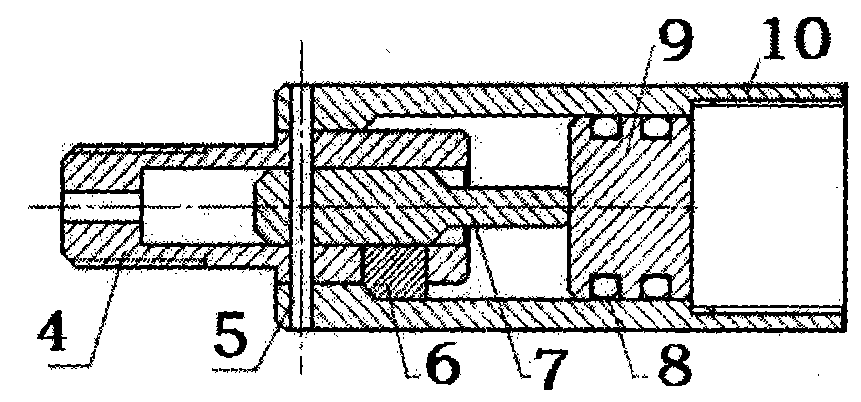

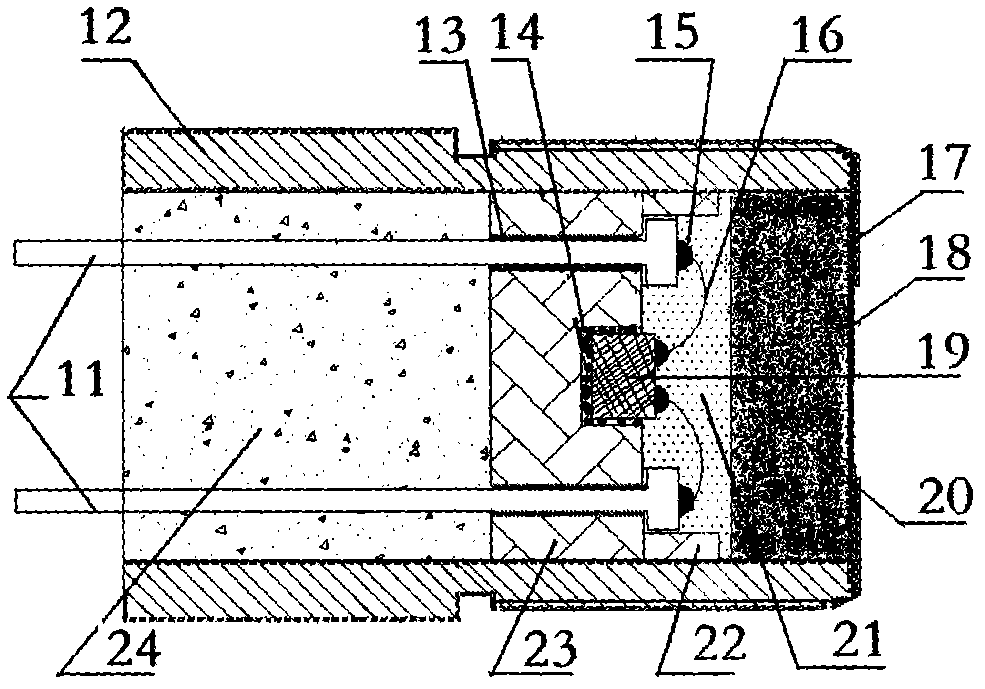

[0018] A small, quick-detachable pyrotechnic unlocking bolt is composed of an unlocking bolt body, a sealing ring, and a semiconductor bridge-type pressure cartridge. By optimizing the structural size parameters and miniaturization design of the unlocking bolt body and the semiconductor bridge-type pressure cartridge, the axial length of the entire unlocking bolt is between 60-65mm, and the radial dimension is not greater than 16mm, realizing the miniaturization of the unlocking bolt. The body structure of the unlocking bolt connects the semiconductor bridge type pressure cartridge through the thread of M14×1-6H. By pre-calculating factors such as the separation starting force of the pyrotechnic unlocking bolt, the volume of the drug chamber, and the design requirements for the charge margin, it is determined that the charge in the semi-conductor bridge pressure cartridge is divided into two layers. The second layer is filled with 30mg of 2 / 1 camphor propellant. By filling th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com