A vertical take-off and landing communication maintenance equipment

A technology for vertical take-off and landing and maintenance equipment, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., which can solve the problems of inconvenient maintenance for workers, time-consuming and laborious, and difficulty in climbing communication towers, and improve maintenance efficiency. , Reduce the amount of high-altitude operations and improve the efficiency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

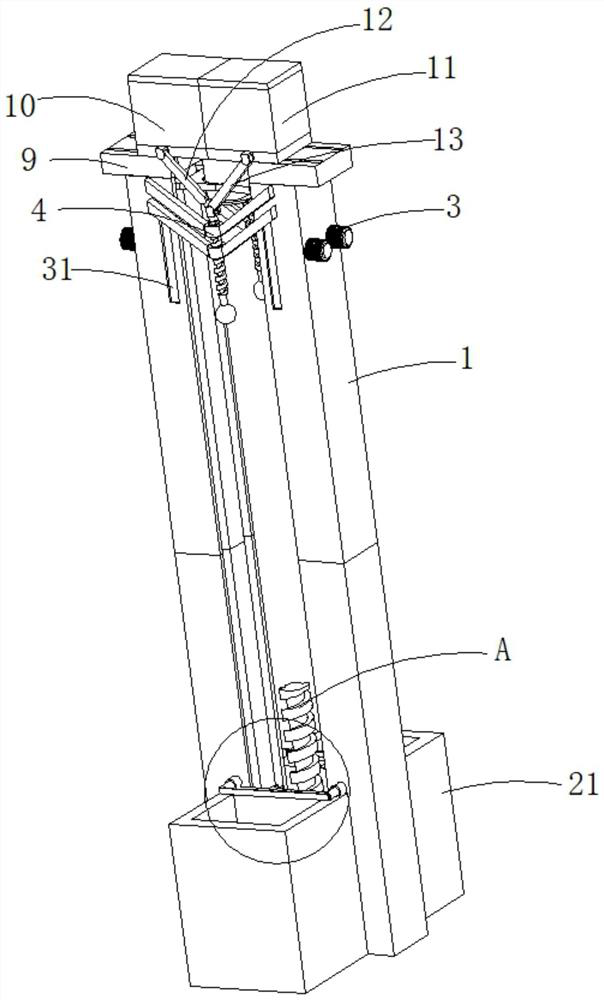

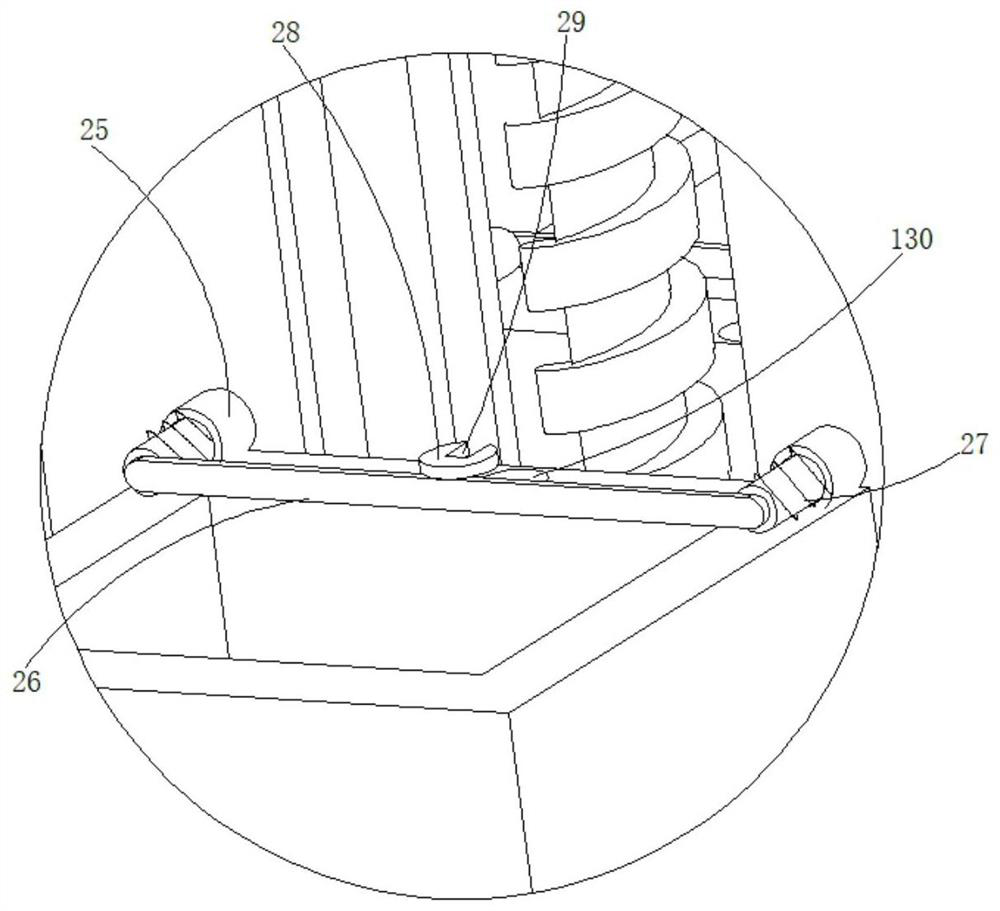

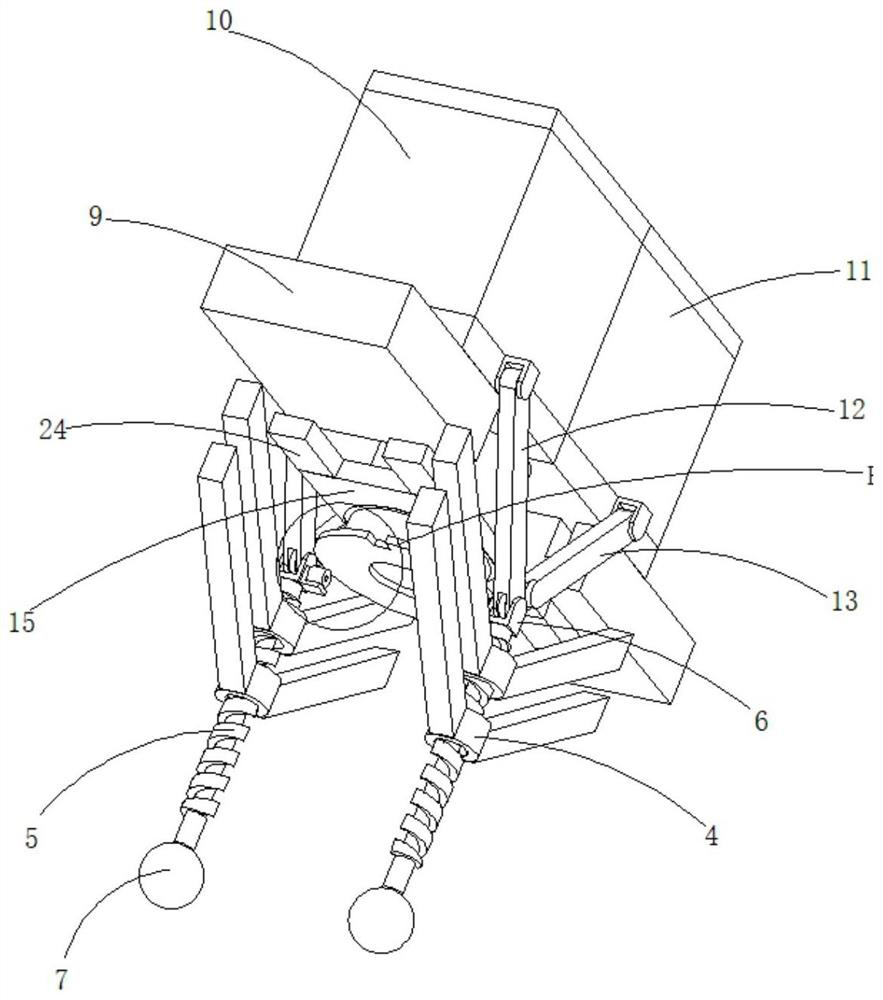

[0032] refer to Figure 1-8, a vertical take-off and landing type communication maintenance equipment, comprising two opposite columns 1, the opposite sides of the two columns 1 are slidingly connected with a lifting table, the top of the lifting table is fixedly connected with a first screw rod, and the column 1 is close to The outer wall of the top is also provided with a driving motor 3, the driving end of the driving motor 3 is connected with the lifting table through a cable, and the outer wall of the column 1 close to the top is fixedly connected with a symmetrically distributed nut seat 4 through a bracket, and the nut seat 4 is internally threaded. There is a second screw rod 5, the top of the second screw rod 5 is rotatably connected with the connecting seat 6, the bottom end of the second screw rod 5 is connected to the limit ball 7 through the rotating shaft, and the top of the lifting workbench is provided with The transmission part, the opposite side of the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com