Removal technology of nitrogen oxides generated in chlorobenzene thermal insulation nitration

An adiabatic nitration and nitrogen oxide technology, which is applied in the preparation of nitro compounds, the preparation of organic compounds, and organic chemistry, etc., can solve problems such as liquid phase product pollution, and achieve high material utilization, less exhaust gas emissions, and reduced operation. effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The main process equipment is: static mixer, absorption device, gas-liquid separation equipment and flash tower, etc.

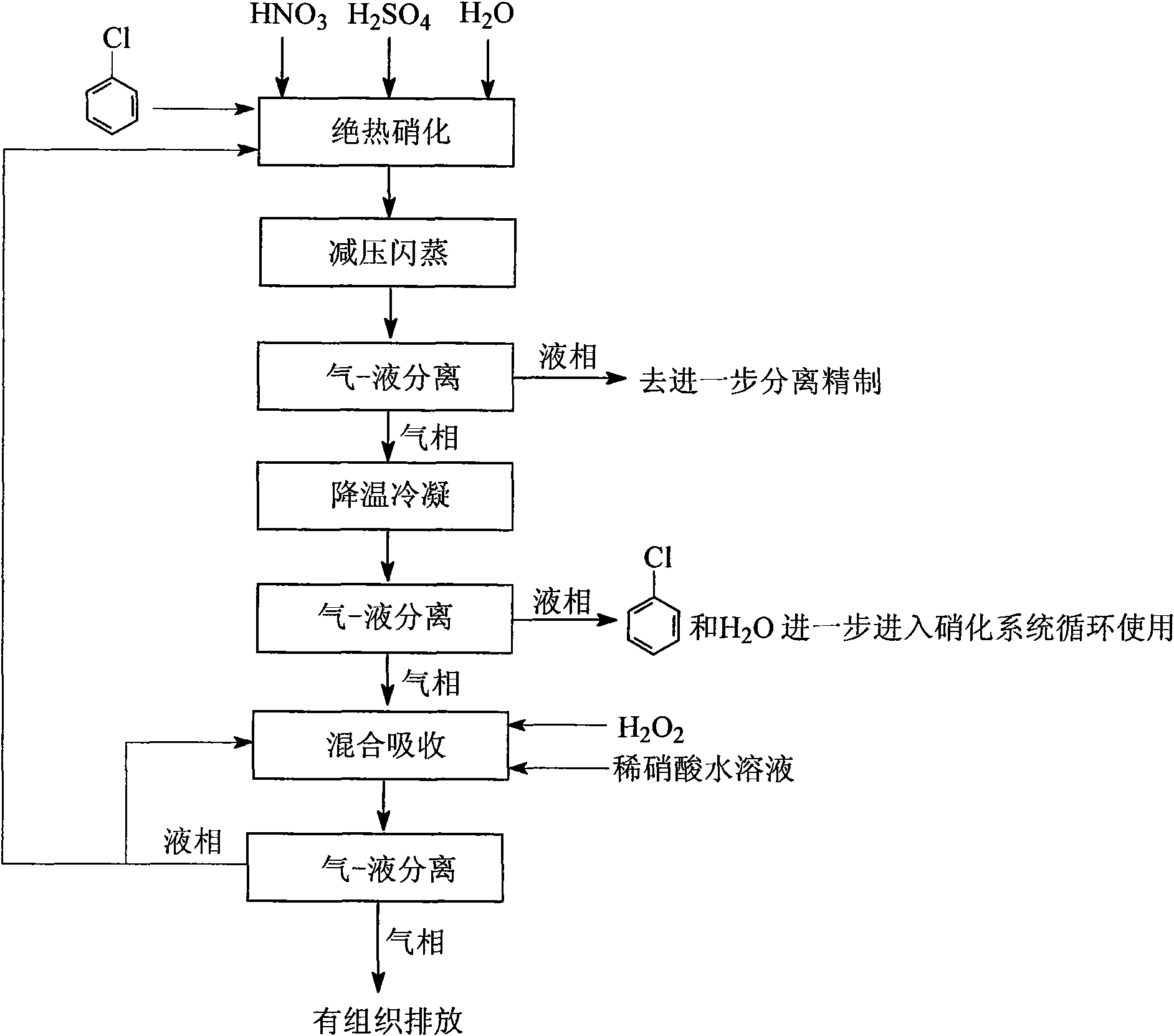

[0030] Such as figure 1 As shown, a method for removing nitrogen oxides produced in the adiabatic nitration process of chlorobenzene, the process steps are as follows:

[0031] (1) Adiabatic nitrification: In the SV-type adiabatic nitrification static mixing reactor, the mixed acid of the nitration reaction is mixed with industrial grade mass fraction of 98% sulfuric acid, 65% nitric acid and waste acid in a certain proportion. The dehydration value of the mixed acid is 2.0, the molar ratio of chlorobenzene to nitric acid is 1.1:1.0, mixing chlorobenzene and mixed acid to produce a nitration reaction, the temperature of the material after the nitration reaction is about 160°C, and the reacted material enters the next step;

[0032] (2) Reduced pressure flash evaporation: In the flash tank, the absolute operating pressure is 0.08MPa, and the material after ...

Embodiment 2

[0039] The main process equipment is: static mixer, absorption device, gas-liquid separation equipment and reduced pressure flashing equipment, etc.

[0040] Such as figure 1 As shown, a method for removing nitrogen oxides produced in the adiabatic nitration process of chlorobenzene, the process steps are as follows:

[0041] (1) Adiabatic nitrification: In the SV-type adiabatic nitrification static mixing reactor, the mixed acid of the nitration reaction is mixed with industrial grade mass fraction of 98% sulfuric acid, 65% nitric acid and waste acid in a certain proportion. The dehydration value of the mixed acid is 3.0, the molar ratio of chlorobenzene to nitric acid is 1.1:1.0, mixing chlorobenzene and mixed acid to cause a nitration reaction, the temperature of the material after the nitration reaction is about 140°C, and the reacted material enters the next step;

[0042] (2) Reduced pressure flash evaporation: In the flash cooler, at an absolute operating pressure of 0.04 M...

Embodiment 3

[0049] The main process equipment is: static mixer, absorption device, gas-liquid separation equipment and reduced pressure flashing equipment, etc.

[0050] Such as figure 1 As shown, a method for removing nitrogen oxides produced in the adiabatic nitration process of chlorobenzene, the process steps are as follows:

[0051] (1) Adiabatic nitrification: In the SV type adiabatic nitrification static mixing reactor, the mixed acid of the nitration reaction is made by mixing industrial grade mass fraction of 98% sulfuric acid, 65% nitric acid and water in a certain proportion, and the dehydration value of the mixed acid is 4.0 , The molar ratio of chlorobenzene to nitric acid is 1.05:1.0, mixing chlorobenzene and mixed acid to produce a nitration reaction, the temperature of the material after the nitration reaction is about 120°C, and the reacted material enters the next step;

[0052] (2) Vacuum flash evaporation: The absolute operating pressure in the flash tank is 0.02MPa, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com