Method for quickly remitting inhibition of nitrite in anaerobic ammonium oxidation

An anaerobic ammonia oxidation and nitrous nitrogen technology, applied in the direction of anaerobic digestion treatment, to avoid secondary pollution, avoid large fluctuations, and reduce infrastructure costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

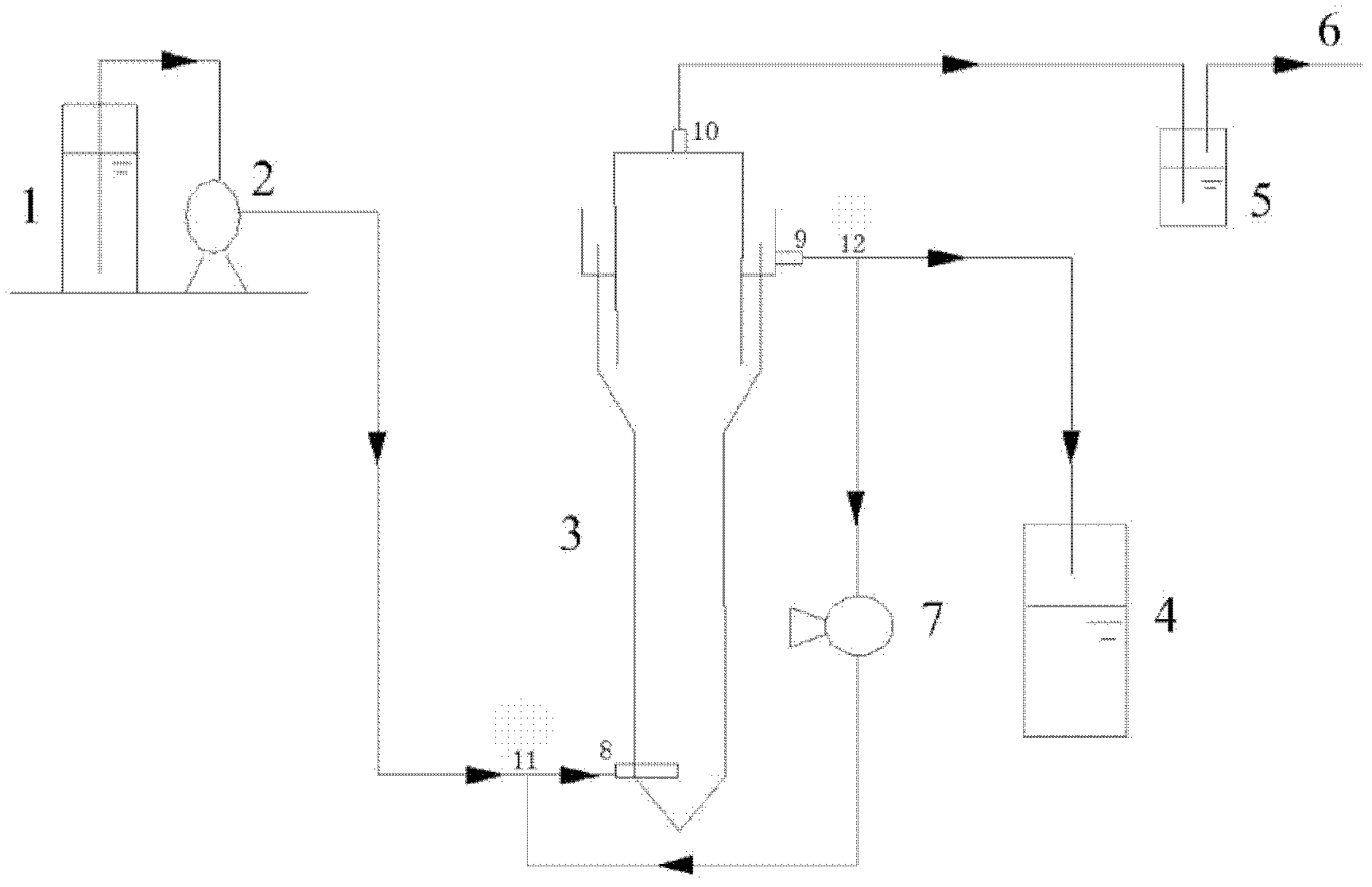

[0029] Upflow Anammox Reactor (effective volume 0.1m 3 ) works well, and the reactor structure is as follows figure 1 As shown, the anammox reactor system includes a reactor body 3, an inlet tank 1, an outlet tank 4, an inlet peristaltic pump 2, a return peristaltic pump 7 and a water-sealed bottle 5, and the bottom of the reactor body 3 is provided with There is a water inlet 8, a water outlet 9 at the upper end, and an air outlet 10 at the top; the water inlet tank 1 is connected to the water inlet peristaltic pump 2, and the water inlet peristaltic pump 2 is connected to the water inlet through the three-phase valve A11, three-phase The other inlet of valve A is connected with the return peristaltic pump, and the water outlet is connected with the return peristaltic pump 7 and the water outlet tank 4 respectively through the three-phase valve B12, and the air outlet is connected with the water-sealed bottle 5, and the water-sealed bottle 5 Vent 6 is arranged on the top.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com