Burner arrangement and method for operating a burner arrangement

A burner and burner technology, applied in the direction of combustion methods, burners, gas turbine devices, etc., can solve the problems of high life cycle cost, high NOx emission level, etc., and achieve the effect of good mixing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

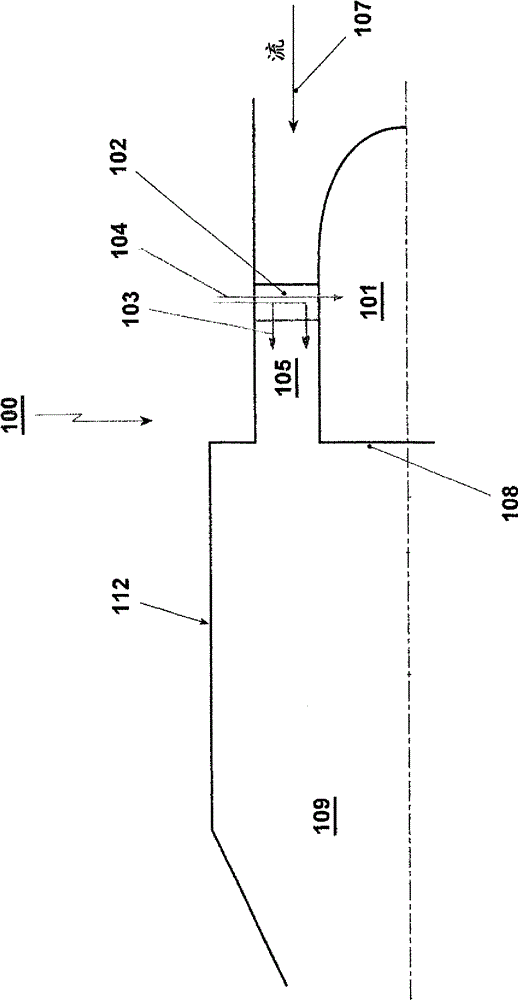

[0054] figure 1 A reheat burner arrangement 100 incorporating a center body 101 is shown. The shown center body starts upstream of the injection plane 102 (lobe), causing fuel 103 and carrier gas 104 to be injected into the center body 101 , and then the center body continues downstream to the outlet 108 of the burner arrangement 100 . The central body 101 is actively connected to the main flow 107 of hot gas. The center body 101 provides better mixing, matching the burner and burner zone. With regard to the premix burner according to the invention, the central body 101 may be provided with a fuel supply line (not shown). The central body 101 presents at its end 108 a cylindrical or quasi-cylindrical end relative to the cross-sectional area between the annular duct 105 and the combustion chamber 109 behind it in the direction of flow of the main flow 107 . A full, partial or intermediate conical configuration of the surface of the central body relative to the cross-sectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com