Grade test method and device of textile colour fastness colour difference

A test method and technology of color fastness, applied in textile testing, color/spectral characteristic measurement, material inspection products, etc., can solve the problems that do not involve automatic calibration and adjustment functions of color fastness rating detection, and achieve reduction The interference of labor intensity and human factors, and the effect of objective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

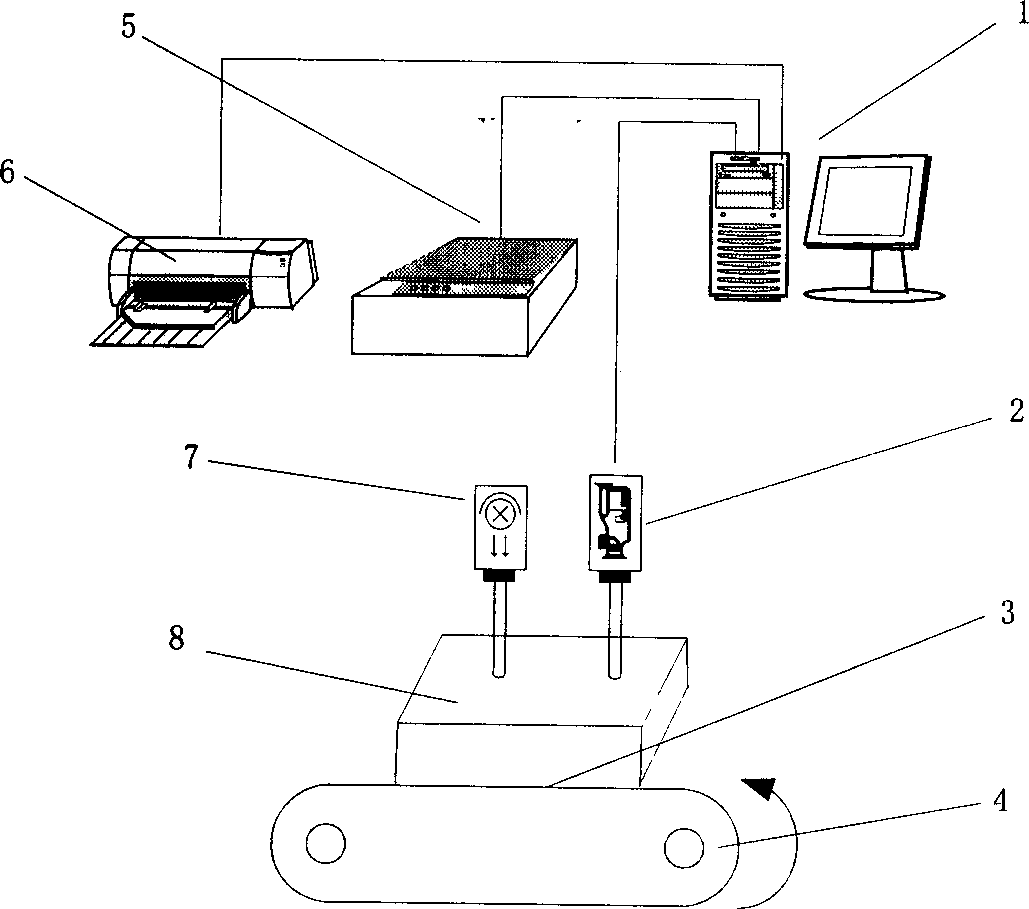

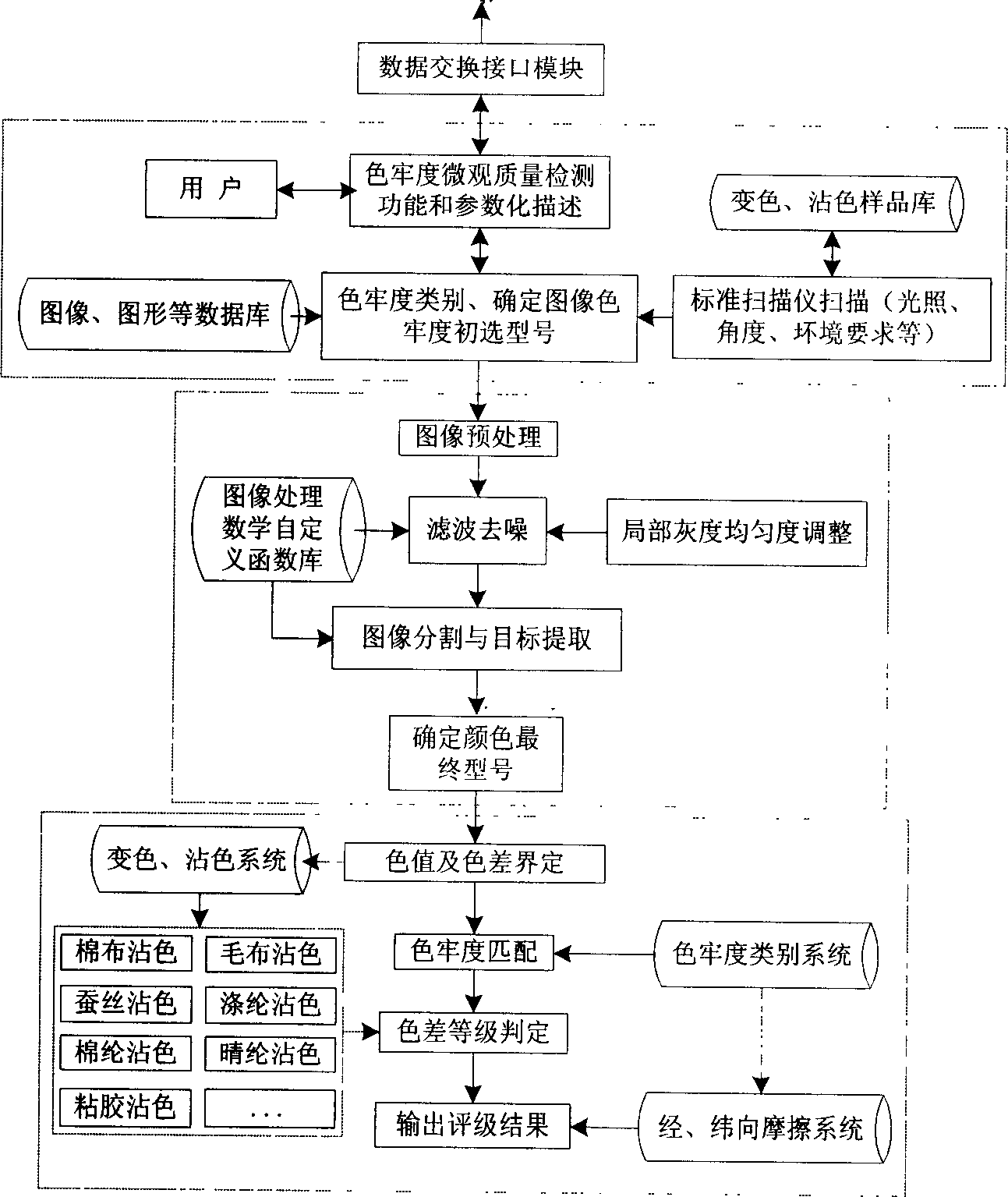

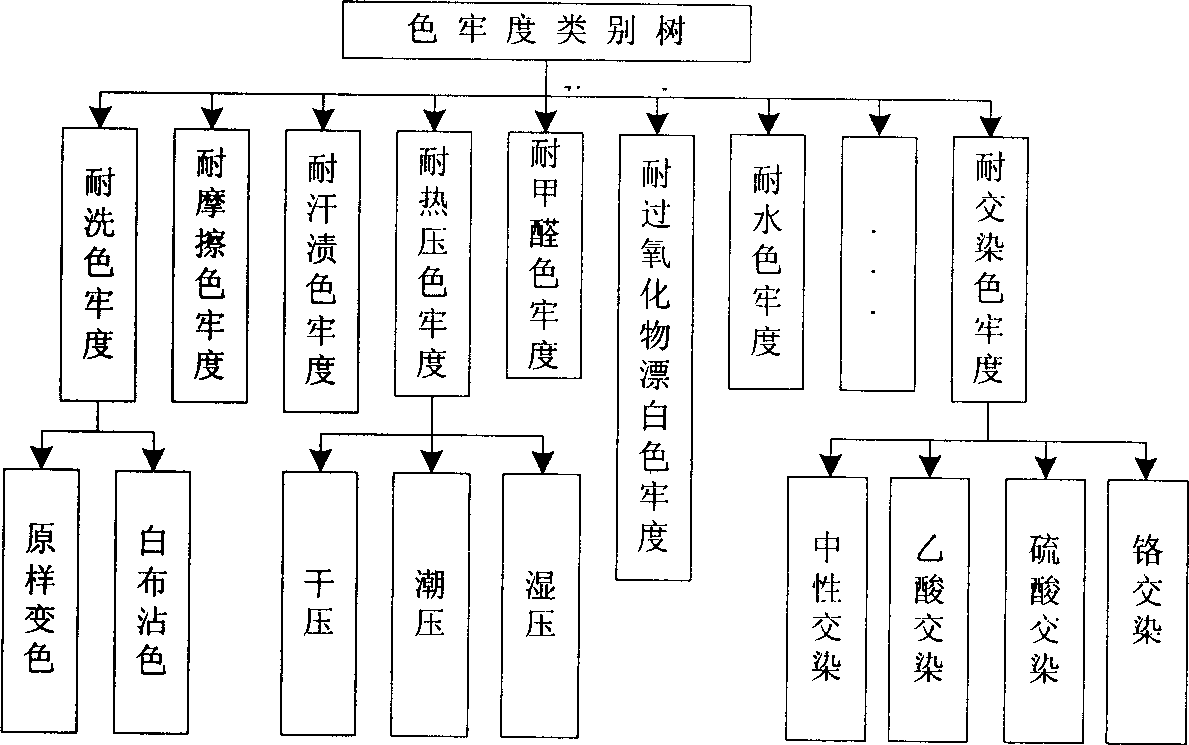

[0024] The present invention is made up of scanner, illumination system, photographing equipment, image acquisition equipment and computer with color fastness and color difference rating test image processing and recognition; wherein the color fastness and color difference rating test image processing recognition includes staining color fastness image processing and Color fastness image processing and high-precision pattern recognition processing system.

[0025]Scanner or camera digital input equipment has the following important parameters: resolution, size, input and output multiples, sharpness, etc. Their settings have a greater impact on the final test results. Through trial and error, the color fastness testing system determines that the relevant parameters are mainly: original type setting (Original), scanning mode setting (Mode), scanning resolution setting (Input / Output), magnification setting (Scale to) and Sharpness setting (Sharpness), etc. The main considerations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com