Method for dyeing and finishing polyester-spandex fabric

A processing method and technology of polyester spandex, applied in the field of dyeing and finishing of polyester spandex fabrics, can solve the problems of poor dyeing reproducibility, poor color fastness, elasticity and strength damage of spandex, and achieve full hand feeling, distinctive features and good elasticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: pretreatment stage

[0032] Spandex and polyester fibers use a lot of fiber oil and winding oil in the spinning process, including some silicon-containing additives. In the weaving process of chemical fiber gray cloth, in order to increase the smoothness of the warp yarn surface, improve the wear resistance and strength, and reduce the phenomenon of end breakage, the warp yarn generally needs to be sized and oiled before weaving. If the pre-treatment is not cleaned, it will easily form color spots and tar spots that are difficult to remove together with the precipitated polyester oligomers during dyeing.

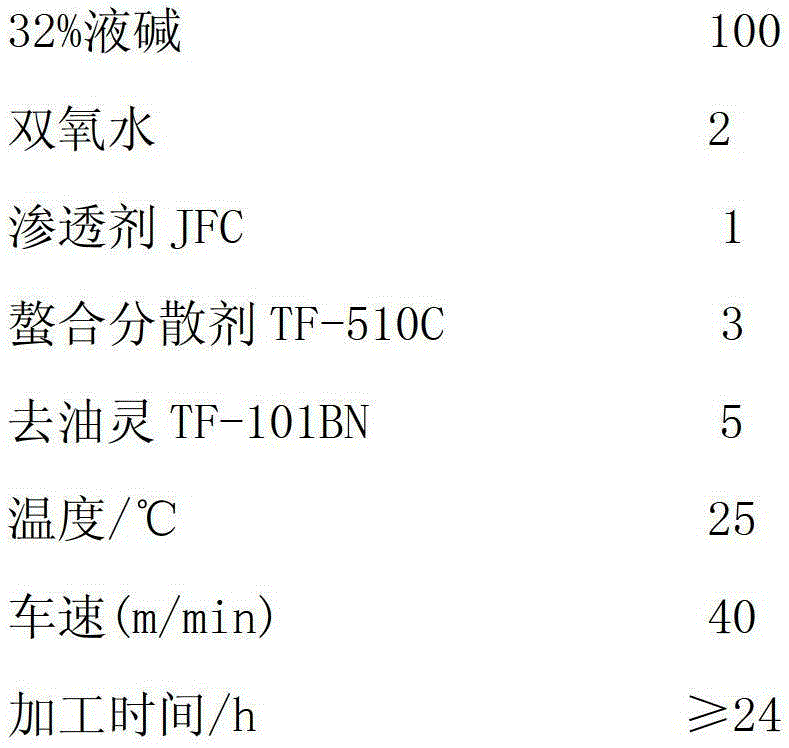

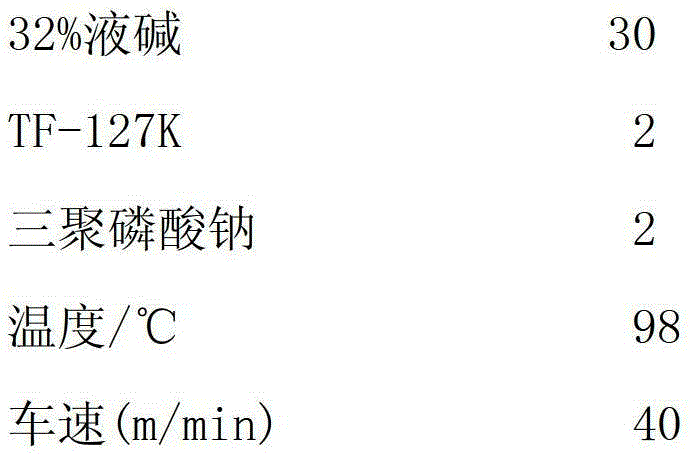

[0033] 1.1 cold stack

[0034] Process prescription (g / L) and conditions are as follows:

[0035]

[0036] In the above process, the chelating dispersant TF-510C can prevent equipment and fabrics from being stained, has the functions of scale inhibition and scale removal, and has good compatibility with desizing liquid. Used in combination with Quy...

Embodiment 2

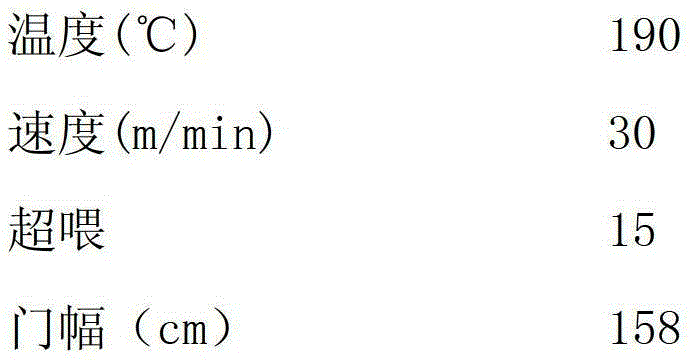

[0044] Example 2: Pre-typing

[0045]Because this kind of cloth contains spandex, it will shrink obviously due to heat and humidity during the dyeing and finishing process. Therefore, this kind of cloth should be pre-shaped before dyeing to prevent it from affecting the dyeing effect due to serious shrinkage during the dyeing process. The purpose of pre-shaping is to eliminate the internal stress of spandex, so that the quality indicators such as fabric width, square meter weight and fabric elasticity are in a stable state, which is easy to control and will not change greatly in subsequent processes. If the presetting temperature is too high and the time is too long, the fabric will feel hard and yellow, and the strength and elasticity of the fabric will be damaged; if the temperature is too low and the time is too short, the wrinkle resistance will be poor and the effect will not be achieved, so strict Control the presetting process. When ordering, more than a dozen units of...

Embodiment 3

[0050] Example 3: Dyeing

[0051] Due to the characteristics of the spandex fiber itself, the dye tends to stick to the surface of the fiber during the dyeing process of the fabric and cannot enter the interior of the fiber, resulting in poor color fastness of the fabric; The stretch effect of the fabric.

[0052] The main purpose of polyester / spandex fabric dyeing is to reduce the tension on the fabric under high temperature conditions. Otherwise, the fabric will be stretched and its elastic recovery will be greatly affected. Because of this, overflow jet dyeing machines are often used to keep the fabric in a relaxed state while under pressure and avoid fabric shrinkage.

[0053] Polyester fiber must be dyed at high temperature and high pressure, while spandex is not resistant to high temperature, especially under acidic or alkaline conditions with high temperature and long time, it is easy to cause brittle damage of spandex yarn, decrease in strength, and cause broken yarn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com