Non-steaming cold pad-batch process of all-cotton or polyester-cotton fabric

A cold pad-batch and fabric technology, applied in textiles and papermaking, fiber treatment, biochemical fiber treatment, etc., can solve the lack of serialization, specialization, standardization and unified testing standards, product whiteness, wool effect, strong presentation Instability, unable to meet the development requirements of the cold pad batch process, etc., to achieve the effects of shortened stacking time, good whiteness, and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

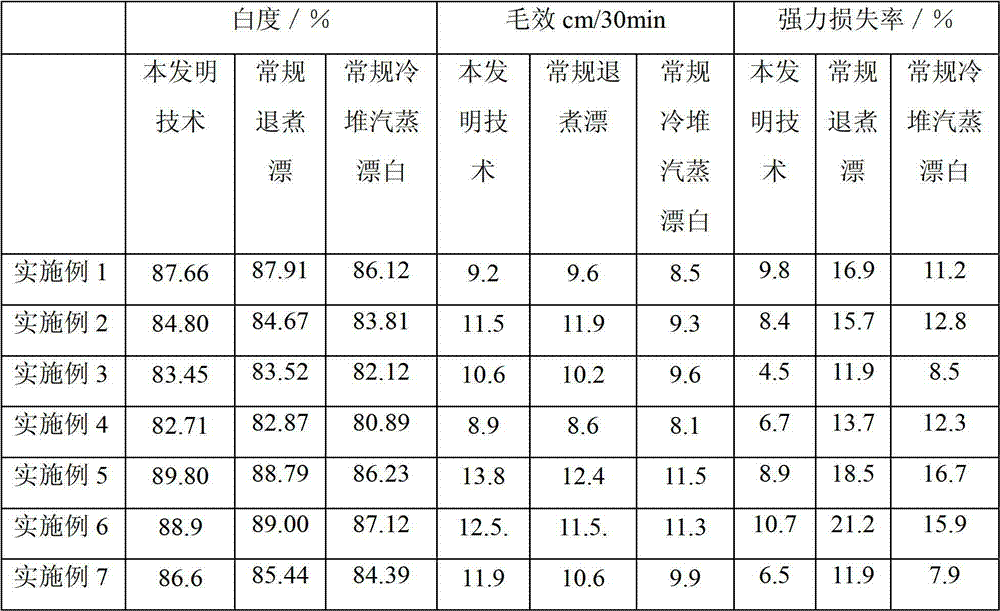

Examples

Embodiment 1

[0024] 1) The gray cloth after singeing is subjected to two dipping and two rolling in the one-bath working solution of desizing, scouring and bleaching, and the liquid-carrying rate of the gray cloth is 100%;

[0025] The one-bath working liquid for desizing, scouring and bleaching is sodium hydroxide: 50g / L, scouring penetrant FK-ST18: 10g / L, Wonderful PLA: 8g / L and hydrogen peroxide (100%): 28g / L aqueous solution ;

[0026] 2) Roll the textiles on a movable and rotating rolling machine, and wrap the rolled cloth tightly with a plastic film; then slowly rotate at a temperature of 25°C, and stack at a speed of 6-8 rpm. 6 hours to achieve the diffusion and penetration of the working fluid in the fabric.

[0027] 3) Then wash in hot water four times at 90°C, wash in warm water at 50°C twice, and wash in cold water at room temperature, and finally dry the fabric.

Embodiment 2

[0029] 1) The gray cloth after singeing is subjected to two dipping and two rolling in the one-bath working solution of desizing, scouring and bleaching, and the liquid-carrying rate of the gray cloth is 95%;

[0030] The one-bath working solution for desizing, scouring and bleaching is multi-functional scouring bleach FK-JL06: 45g / L, scouring penetrant FK-ST18: 6g / L, Wonderful PLA: 6g / L and hydrogen peroxide (100%): 20g / L aqueous solution;

[0031] 2) Roll the textiles on a movable and rotating rolling machine, and wrap the rolled cloth tightly with plastic film; then slowly rotate at a temperature of 25°C, and stack at a speed of 8-10 rpm, time 8 hours to achieve the diffusion and penetration of the working fluid in the fabric.

[0032] 3) Then wash three times with hot water at 95°C, twice with warm water at 60°C and once at room temperature, and finally dry the fabric.

Embodiment 3

[0034] 1) The gray cloth after singeing is subjected to two dipping and two rolling in the one-bath working solution of desizing, scouring and bleaching, and the liquid-carrying rate of the gray cloth is 110%;

[0035] The one-bath working solution for desizing, scouring and bleaching is net cotton enzyme CTA-8800L: 40g / L, penetrant FK-ST20: 8g / L, Wonderful PLA: 5g / L and hydrogen peroxide (100%): 15g / L aqueous solution;

[0036] 2) Roll the textiles on a movable and rotating rolling machine, and wrap the rolled cloth tightly with a plastic film; then slowly rotate at a temperature of 25°C, and stack at a speed of 7-8 rpm. 8 hours to achieve the diffusion and penetration of the working fluid in the fabric.

[0037] 3) Then wash three times in hot water at 95°C, twice in warm water at 55°C and once in room temperature water, and finally dry the fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gross effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com