Dyeing technology of polyester knitted fabric

A knitted fabric and polyester technology, which is applied in the dyeing process of polyester knitted fabric, can solve the problems of poor water solubility, easy sedimentation, and low color fastness of polyester cloth, and achieve long-lasting color, enhanced whiteness, and high color fastness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

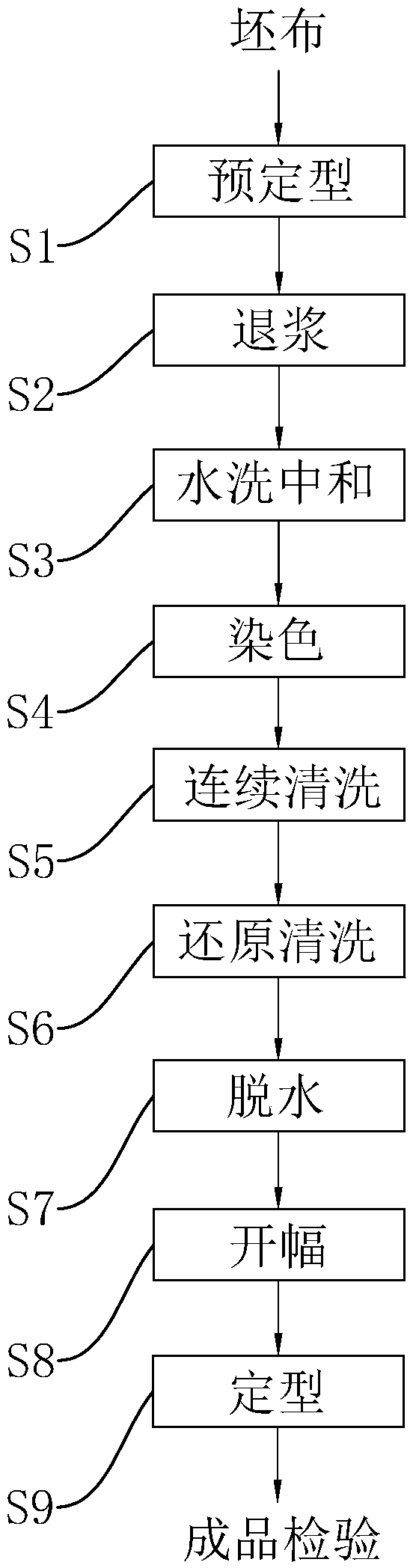

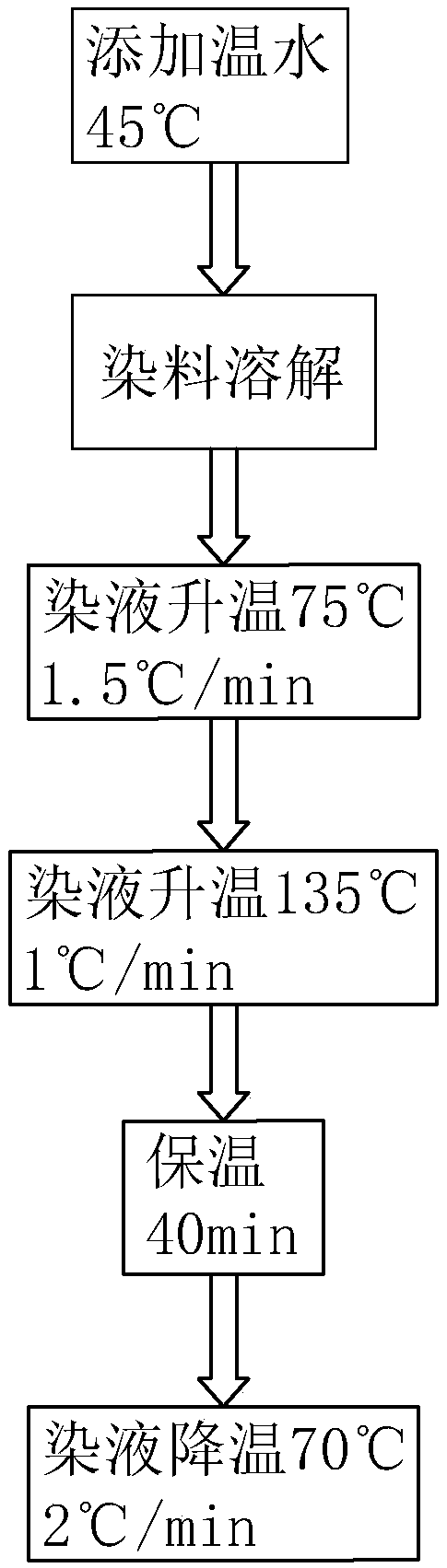

Method used

Image

Examples

Embodiment 1

[0058] The difference between embodiment 10-embodiment 13 and embodiment 1 is that, in S4 staining, the temperature of just beginning to add warm water is as follows:

[0059] Example

Example 10

Example 11

Example 12

Example 13

40

50

42

48

[0060] The difference between embodiment 14-embodiment 17 and embodiment 1 is that each material of dyestuff in the S4 dyeing is as follows in percentage: unit: %

[0061]

[0062] The difference between embodiment 18-embodiment 21 and embodiment 1 is that the temperature that rises for the first time in the dyeing machine after adding dyestuff in S4 dyeing is as follows:

[0063] Example

Example 18

Example 19

Example 20

Example 21

Dyeing temperature (°C)

70

80

72

78

[0064] The difference between embodiment 22-embodiment 25 and embodiment 1 is that the temperature that increases for the second time in the dyeing mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com