Antibacterial fabric and processing method thereof

A processing method, antibacterial fabric technology, applied in the field of fabric fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

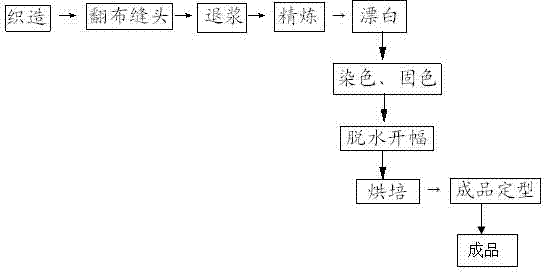

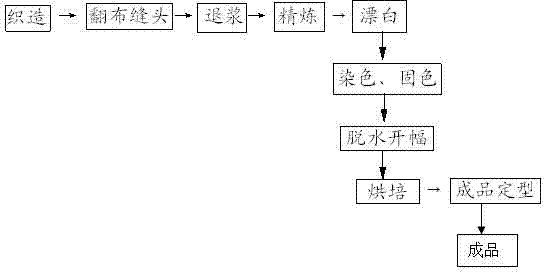

[0025] The raw materials of the fabric are nano-bamboo carbon fiber, nano-silver fiber and polyester fiber. The percentage ratio of each component is as follows: 15% nano-bamboo carbon fiber, 10% nano-silver fiber, and 75% polyester fiber. The fabric is woven with warp and weft. The warp is made of nano-bamboo carbon fiber and polyester fiber twisted low-twisted composite yarn. The percentage ratio of the two is 25:62. The weft is made of nano-silver fiber and polyester fiber. The low-twisted composite yarn twisted with polyester fiber is used as the raw material, and the percentage ratio of the two is 33:78. The fabric processing process is weaving→turning the seam→desizing→refining→bleaching→dyeing, color fixing→dehydration and opening→baking→final shape.

[0026] The specific implementation steps are as follows:

[0027] a) Weaving, using a double-sided knitting machine to obtain white gray cloth;

[0028] b) Turn over the seam head, use a fabric turning machine and a fab...

Embodiment 2

[0037] The raw materials of the fabric are nano-bamboo carbon fiber, nano-silver fiber and polyester fiber. The percentage ratio of each component is as follows: 20% nano-bamboo carbon fiber, 15% nano-silver fiber, and 65% polyester fiber. The fabric is woven with warp and weft. The warp is made of nano-bamboo carbon fiber and polyester fiber twisted low-twisted composite yarn. The percentage ratio of the two is 25:52. The weft is made of nano-silver fiber and polyester fiber. The low-twist composite yarn twisted with polyester fiber is used as the raw material, and the percentage ratio of the two is 33:68. The fabric processing process is weaving→turning the seam→desizing→refining→bleaching→dyeing, color fixing→dehydration and opening→baking→final shape.

[0038] The specific implementation steps are as follows:

[0039] a) Weaving, using a double-sided knitting machine to obtain white gray cloth;

[0040] b) Turn over the seam head, use a fabric turning machine and a fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com