Dyeing process of bamboo-cotton fiber blended fabric

A fiber blending and fabric technology, applied in the field of textile printing and dyeing, can solve the problems of product loss of use value, difference in physical properties, inconsistent color fastness, etc., and achieve the effect of improving color fastness, short process and maintaining consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

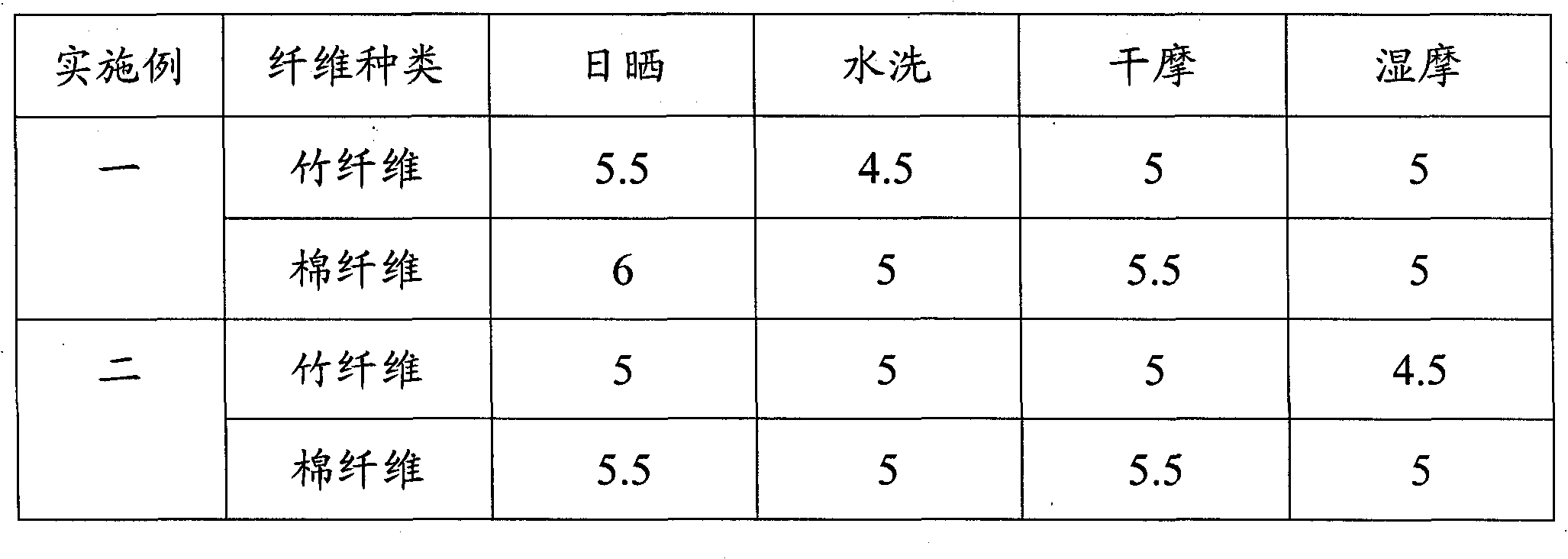

Examples

Embodiment 1

[0021] A kind of dyeing process of bamboo cotton fiber blended fabric, comprises the steps:

[0022] (1) Enzyme desizing and scouring: Prescription of desizing and scouring padding working solution: 7658 amylase 1.5g / L, 301 refining enzyme 0.5g / L, pectinase CR 0.3g / L, penetrant JFC 1.5g / L, chelating agent 0.5g / L; desizing and scouring process conditions: hot water washing temperature 90°C, padding working fluid temperature 65°C, scrapping rate 90%, steam stacking time 90 minutes, temperature 70°C, pH value 6.5;

[0023] (2) Singeing: The speed of the machine is 100m / min, and the temperature of the burner is 1100°C, and the burner is singed with one forward and one reverse burner, and the singeing series reaches more than four grades;

[0024] (3) Oxygen bleaching: Oxygen bleaching padding working fluid prescription: hydrogen peroxide 3.5g / L, sodium silicate 1.5g / L, high-efficiency refining agent TF-125A 1.5g / L, stabilizer 2g / l, chelating agent 3g / L; the technological proce...

Embodiment 2

[0029] A kind of dyeing process of bamboo cotton fiber blended fabric, comprises the steps:

[0030] (1) Enzyme desizing and scouring: Prescription of desizing and scouring padding working solution: 7658 amylase 1.5g / L, 301 refining enzyme 0.5g / L, pectinase CR 0.3g / L, penetrant JFC 1.5g / L, chelating agent 0.5g / L; desizing and scouring process conditions: hot water washing temperature 90°C, padding working fluid temperature 65°C, scrapping rate 90%, steam stacking time 90 minutes, temperature 70°C, pH value 7;

[0031] (2) Singeing: The speed of the machine used is 100m / min, and the burner temperature is 1200°C for one forward and one reverse burner singeing, and the singeing series is required to reach level 4 or above;

[0032] (3) Oxygen bleaching: Oxygen bleaching padding working fluid prescription: hydrogen peroxide 3.5g / L, sodium silicate 1.5g / L, high-efficiency refining agent TF-125A 1.5g / L, stabilizer 2g / l, chelating agent 3g / L; the technological process of oxygen b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com