Agitating friction riveting device and riveting method

A friction stir and riveting device technology, applied in welding/welding/cutting items, welding equipment, non-electric welding equipment, etc., can solve the problem of point-fixed joints not being strong enough, and achieve the effect of excellent room temperature plasticity and excellent connection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] 1. Friction stir riveting of LF2 aluminum alloy sheet

[0036] Plate specification: 2mm+2mm.

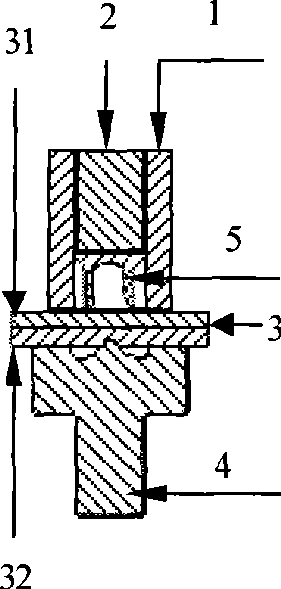

[0037] Rivet II material, size, shape and surface condition: the material is high-strength carbon structural steel, the height is 4mm, the diameter of the nail cover is 8mm, the diameter of the nail bottom is 4mm, and the diameter of the nail neck is 3mm. Both the cap and the bottom of the rivet are flat, and there is a groove I in the shape of a "ten" on the cap, the neck of the nail has no groove, and the surface of the rivet II has no coating.

[0038] The shape and size of the rivet rotary drive rod: the top of the end adopts the shape of a "ten" screwdriver head, and the diameter of the shaft shoulder is 11mm.

[0039] The shape and size of the groove II of the rigid gasket: the groove II is in the shape of a truncated cone, the diameters of the upper and lower bottom surfaces are 8mm and 7mm, and the depth is 1mm. Both the upper and lower bottom surfaces of the circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com