Optical anti-counterfeiting element and manufacturing method thereof

A technology of optical anti-counterfeiting and manufacturing method, which is applied in the directions of printing and information-carrying cards, etc., can solve the problems such as the difficulty of maintaining the integrity and continuity of the mask layer of the opening structure, the formation of a hole structure, and the imperfect image edge of the anti-reflection layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, and not to limit the present invention.

[0017] In order to enable those skilled in the art to better understand the technical solution of the present invention, the optical anti-counterfeiting element prepared according to the present invention and its production process will be described in detail below with reference to the accompanying drawings.

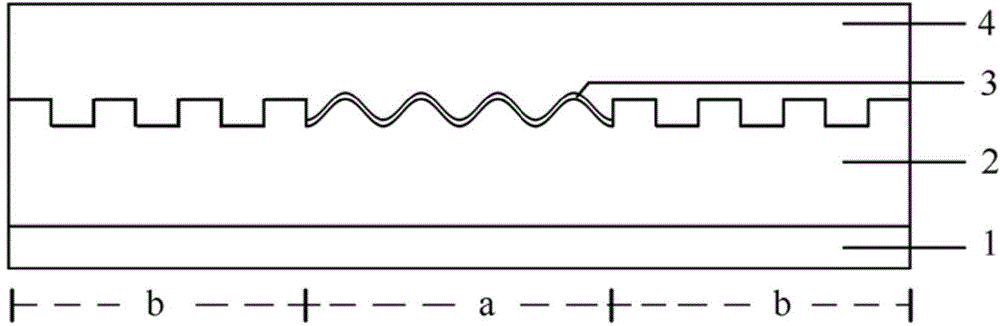

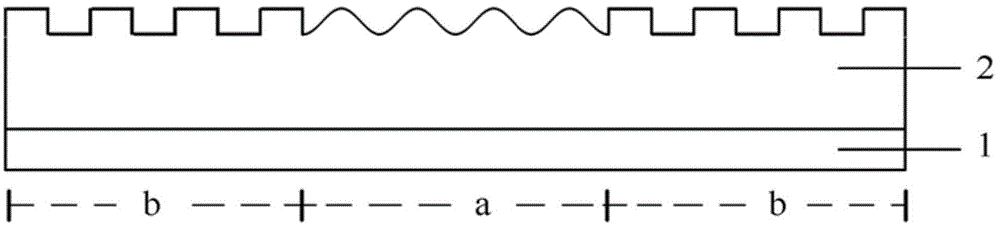

[0018] In order to be able to describe the optical security element and its manufacturing method according to the embodiment of the present invention more vividly, we have formed figure 1 with figure 2 The illustrated exemplary optical security element is taken as an example to exemplarily describe the method according to the present invention, where figure 1 Is a top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com