Fast recovery diode FRD chip and production process for same

A technology for recovering diodes and chips, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of uneven redistribution of metal ions, uneven distribution of metal ions, uneven reverse recovery time, etc. Enhanced voltage stability and reliability, improved flatness, uniform and stable reverse recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] A fast recovery diode FRD chip and its manufacturing process according to the present invention will be further described in detail through specific embodiments below.

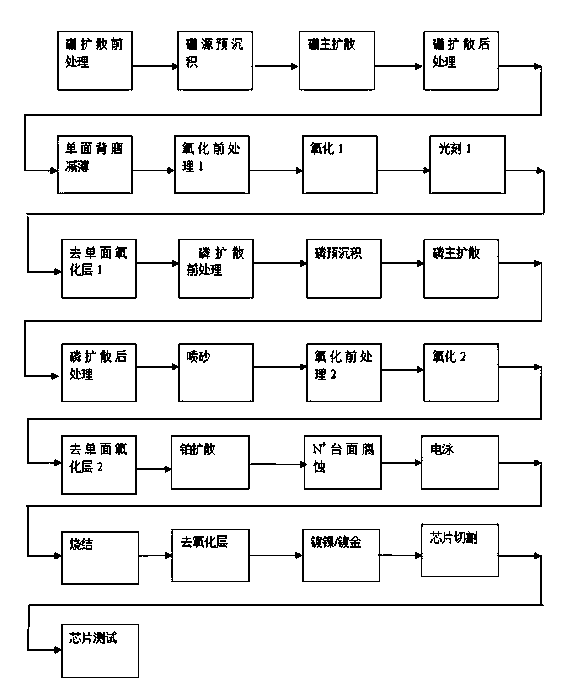

[0034] A kind of production technology of fast recovery diode FRD chip, see image 3 , which has the following steps:

[0035] 1) Pre-diffusion treatment: through electronic cleaning agent SC 2 , Ultrasonic cleaning with deionized water and other processes to chemically treat the surface of the silicon wafer to obtain a clean original N-type silicon wafer;

[0036] 2) Boron source pre-deposition: pre-deposit the cleaned original N-type silicon wafer in a diffusion furnace at 1150-1200 ° C with gas carrying into a liquid boron source (boron tribromide);

[0037] 3) Main diffusion of boron source: carry out deep junction diffusion on the pre-deposited silicon wafer in a diffusion furnace at 1200-1250°C to form a deep P + Floor;

[0038] 4) Post-diffusion treatment: Soak in hydrofluoric acid and ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com