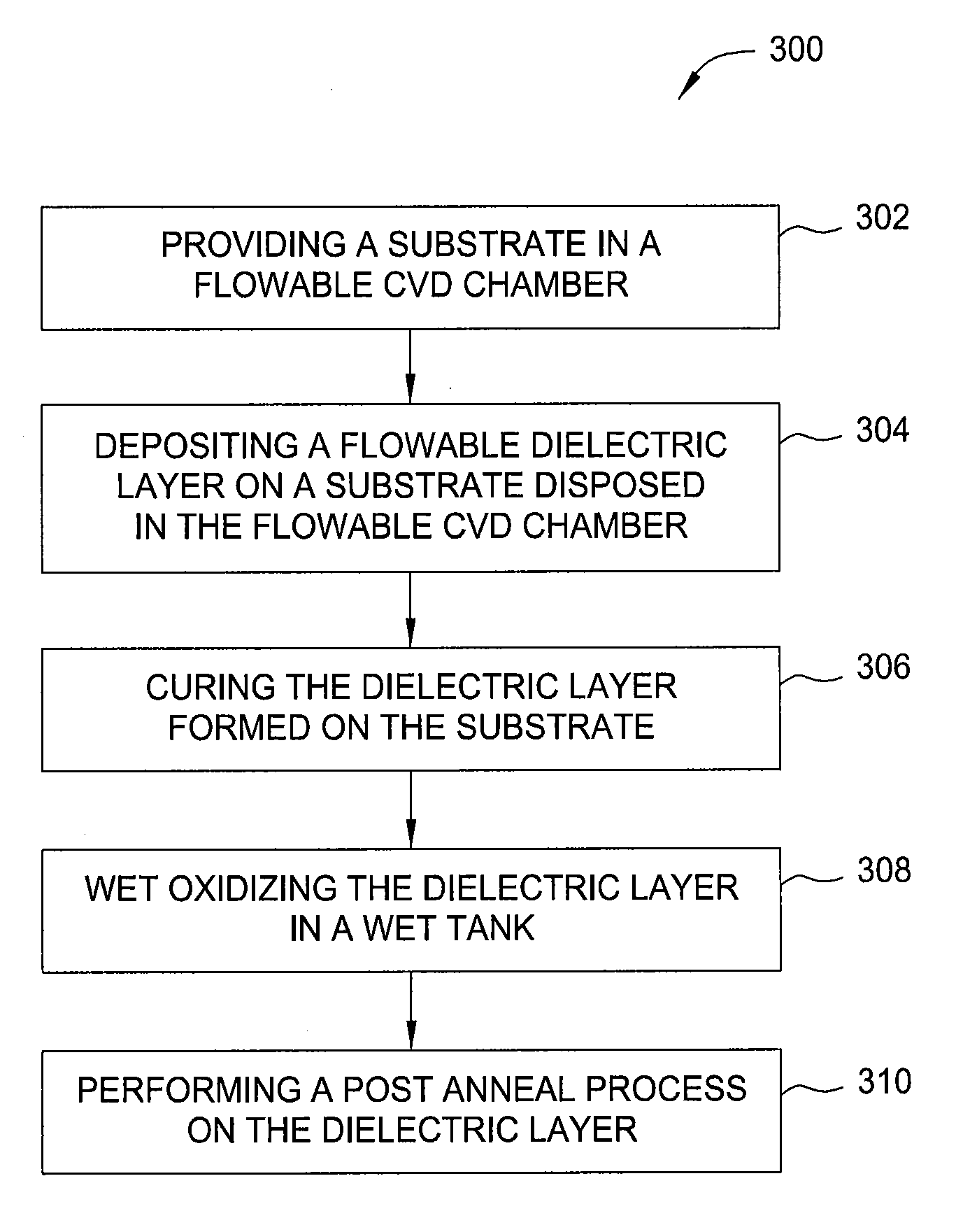

Wet oxidation process performed on a dielectric material formed from a flowable CVD process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

nd

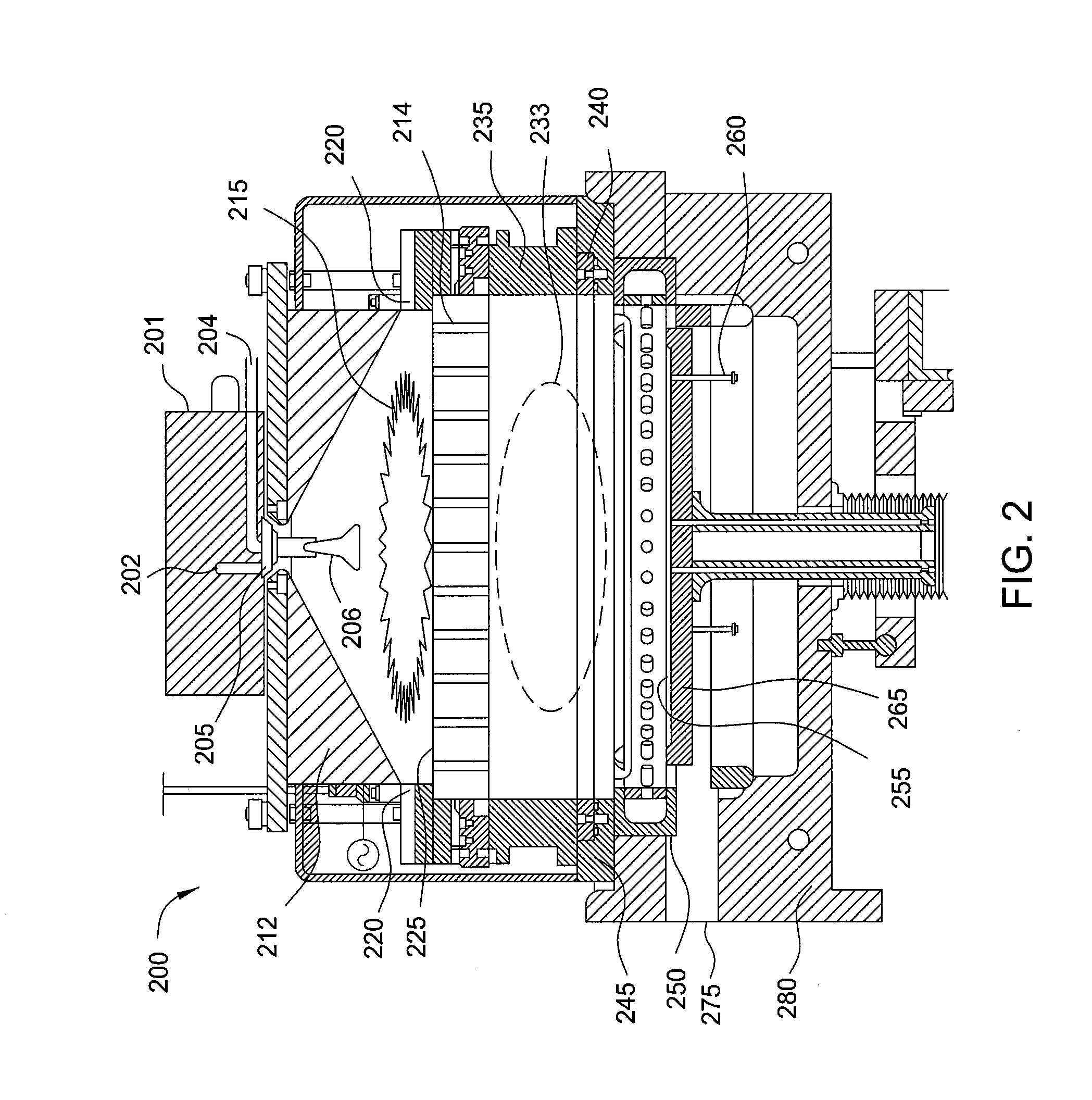

[0019]FIG. 5 is a schematic cross-sectional view of a wet process tank that may be used according to one embodiment of the invention.

[0020]To facilitate understanding, identical reference numerals have been used, where possible, to designate identical elements that are common to the figures. It is also contemplated that elements disclosed in one embodiment may be beneficially utilized on other embodiments without specific recitation.

DETAILED DESCRIPTION

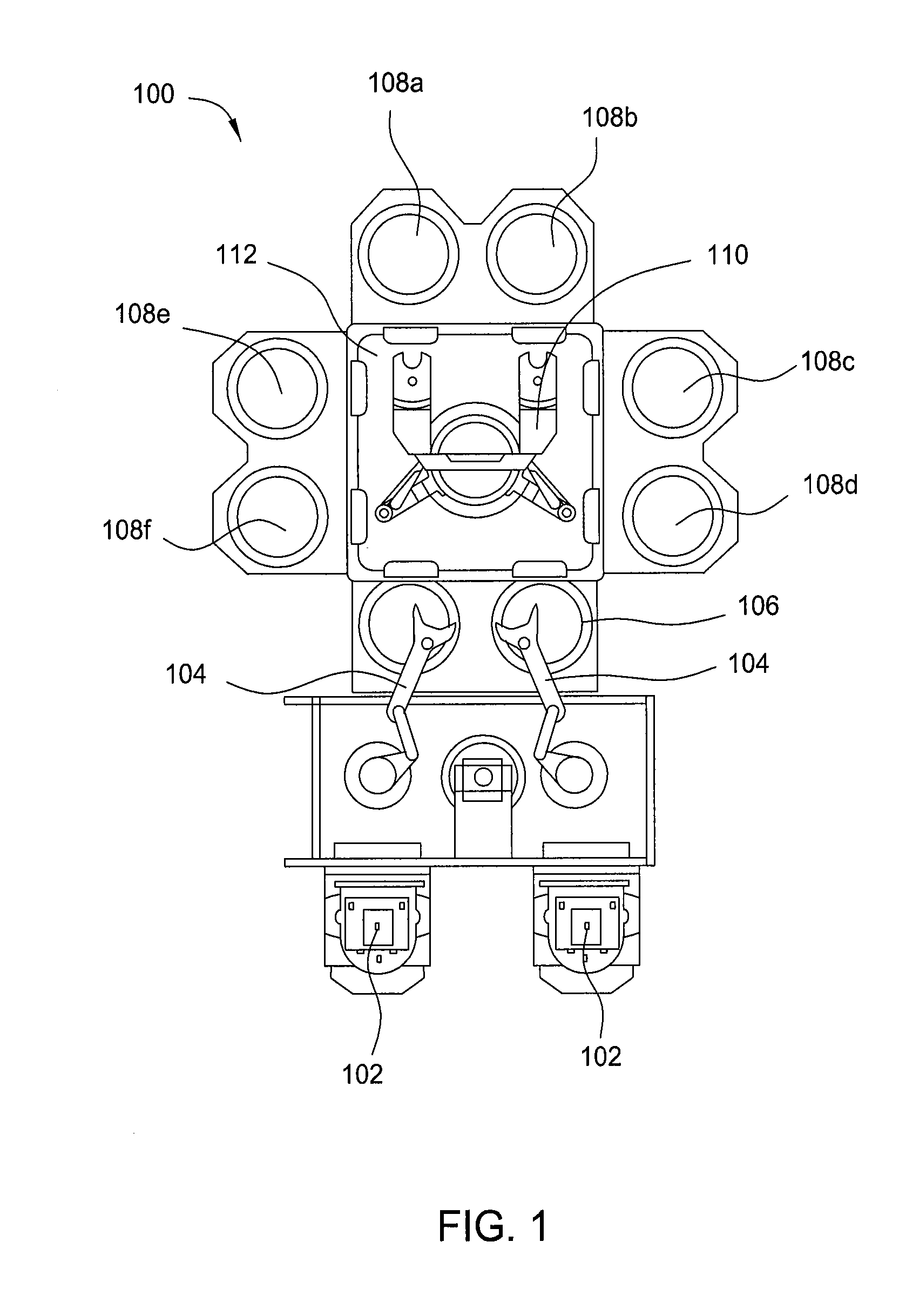

[0021]FIG. 1 is a top plan view of one embodiment of a processing tool 100 of deposition, baking and curing chambers according to disclosed embodiments. In the processing tool 100, a pair of FOUPs (front opening unified pods) 102 supply substrate substrates (e.g., 300 mm diameter wafers) that are received by robotic arms 104 and placed into load lock chambers 106. A second robotic arm 110 is disposed in a transfer chamber 112 coupled to the load lock chambers 106. The second robotic arm 110 is used to transport the substrates from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com