Inferior diesel oil quality change method

A low-quality diesel oil technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc., can solve the problems of not meeting the new diesel quality standards, achieve the effect of increasing cetane number and reducing the content of aromatics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

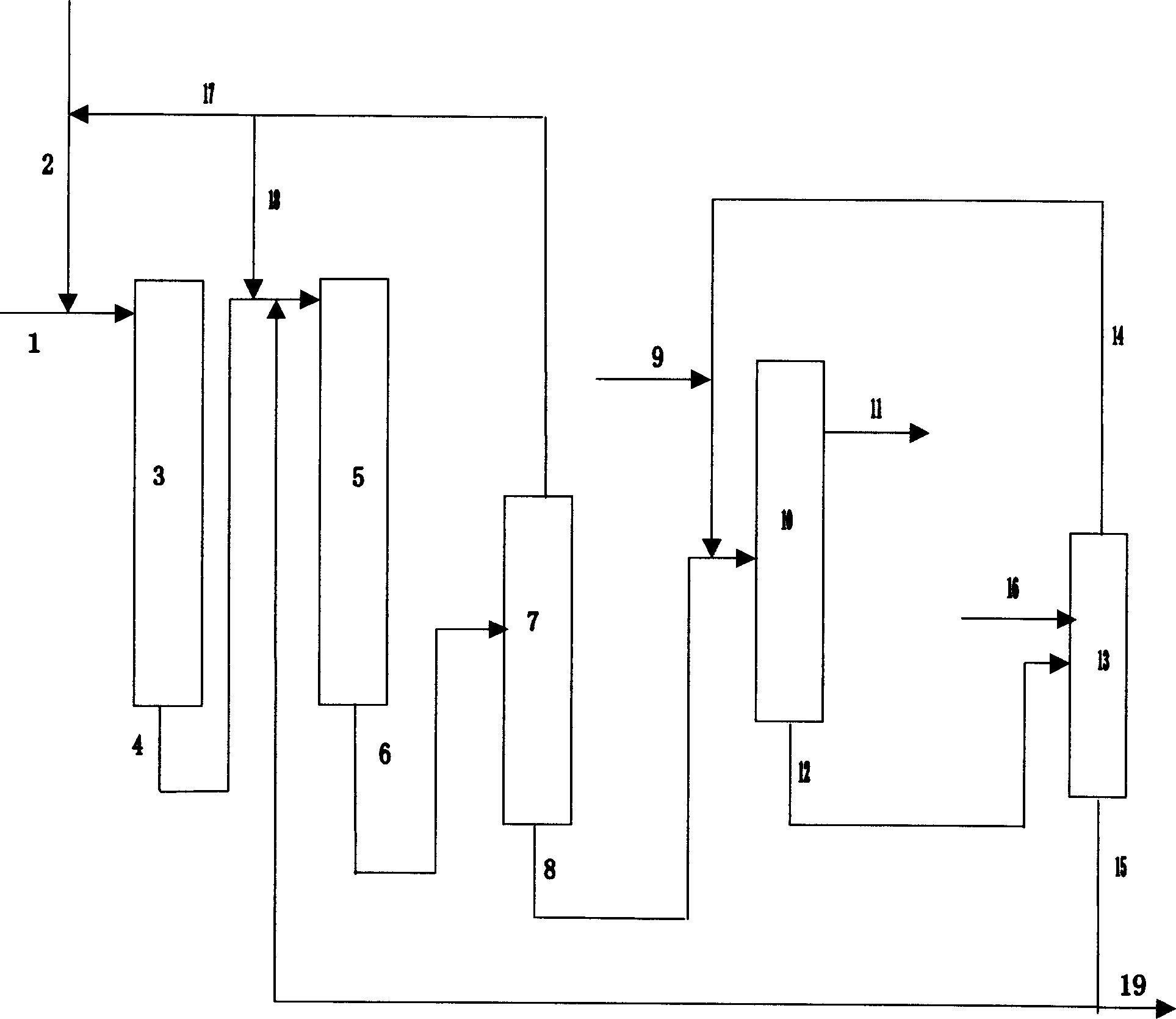

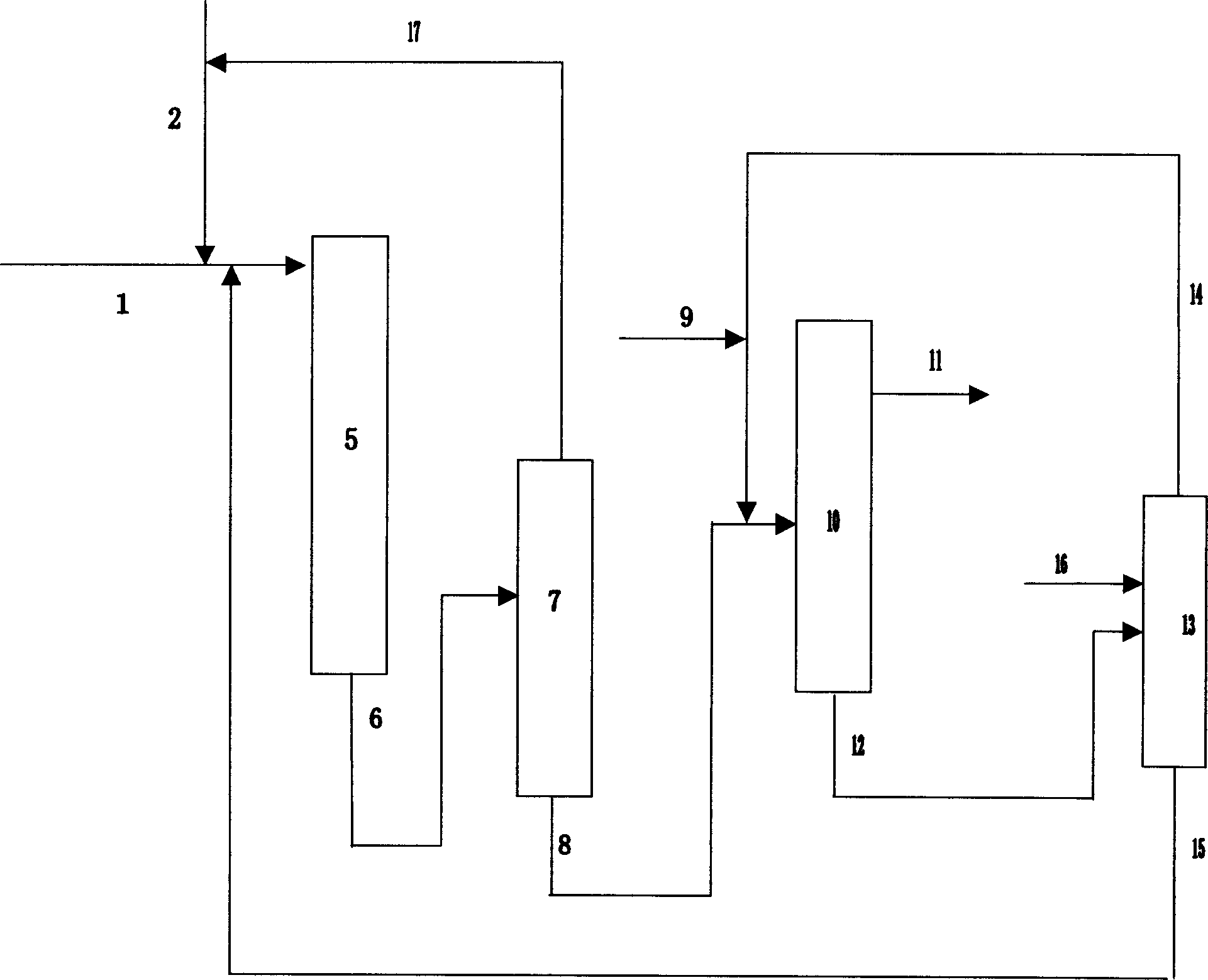

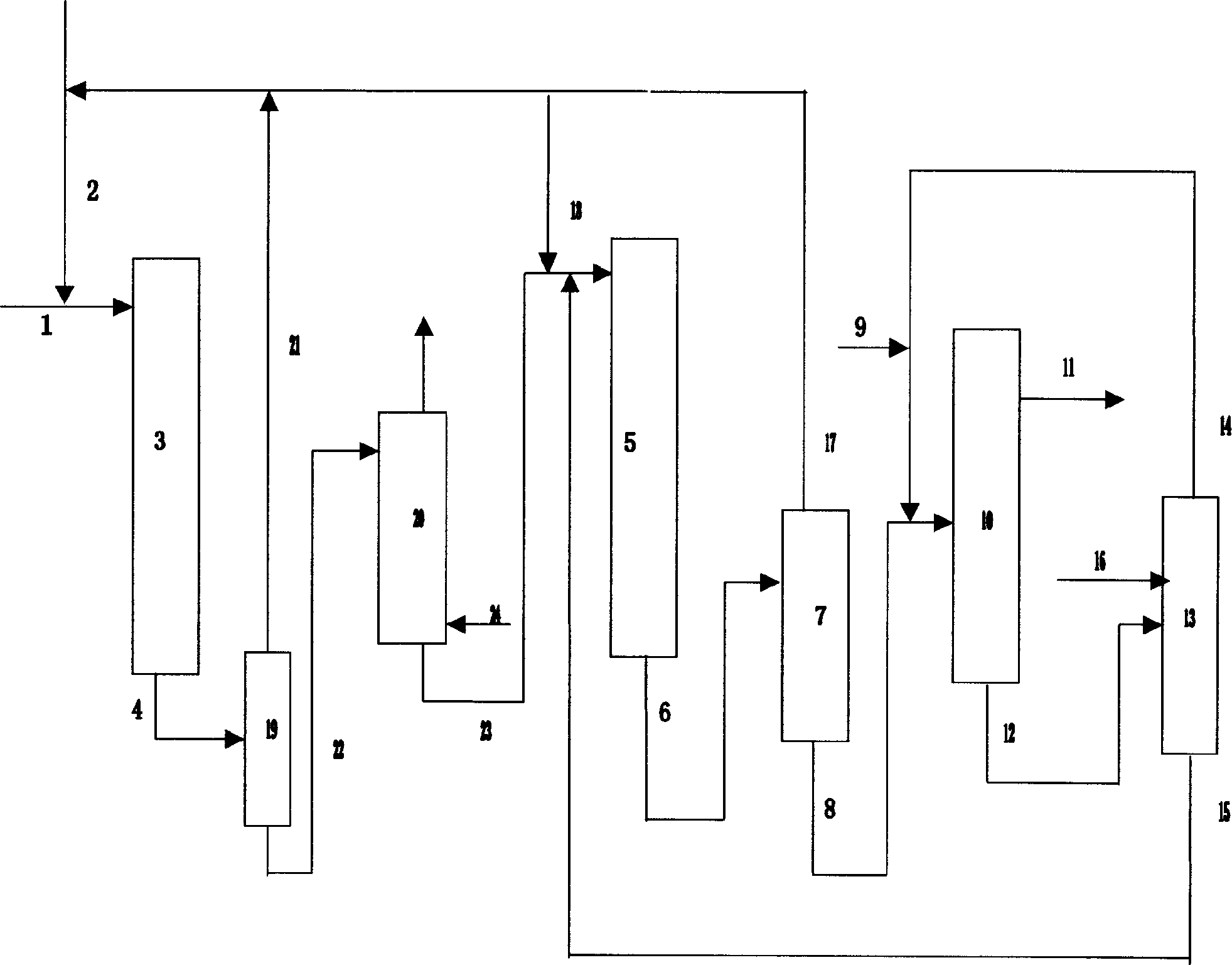

Method used

Image

Examples

Embodiment 8~10

[0028] Numbering

[0029] Numbering

[0030] It can be seen from the above examples that the biggest feature of this combined process is that it rationally utilizes the respective characteristics of the hydrogenation process and the extraction process, while maintaining the diesel fraction yield, it not only greatly reduces sulfur, nitrogen, and aromatics content, also greatly improved the cetane number of diesel products. This allows the production of very high quality diesel products with minimal investment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com