Physical method for preparing vegetable oil

A physical method and vegetable oil technology, applied in the field of oil production, can solve the problems of not involving grape seed oil refining treatment, oil refining method, waste water and oil bottom generation, etc., to reduce oil damage, low refining consumption, and cycle time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

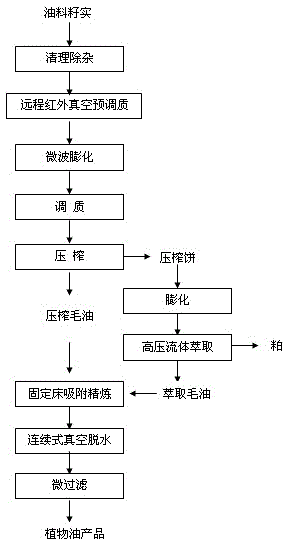

Method used

Image

Examples

Embodiment 1

[0048] Select fresh and mature rapeseed to clean and remove impurities, and then use far-infrared treatment for 3 minutes under the condition of 0.03 MPa, where the power density is 5 w / g, and the irradiation distance is 150 mm; then adjust the microwave power to 100 kw, and treat the rapeseed After microwave puffing for 5 min, the temperature of the puffed rapeseed was 108°C and the water content was 4.5%. Put the rapeseed in a closed container, pour in atomized water at 30°C while stirring, continue stirring for 30 minutes, the stirring rate is 45 rpm, the water content of the tempered rapeseed is 8%, and the temperature is 50°C; Next, the rapeseed at 50°C is conveyed into a twin-screw press for pressing to obtain pressed cake and pressed crude oil; then the pressed cake is directly expanded by an extruder, and a small amount of water is introduced during expansion, and the temperature of the expanded outlet is controlled at 110°C. The water content of the material after coo...

Embodiment 2

[0051] Select fresh and mature flaxseeds to clean and remove impurities, and then use far-infrared treatment for 2.5min under the condition of 0.02 MPa, where the power density is 4 w / g, and the irradiation distance is 160mm; Micro-expanded for 4.5 minutes, the temperature of the expanded flaxseed was 101°C, and the water content was 4.0%. Put the linseed in a closed container, pour in atomized water at 35°C while stirring, continue to stir for 36 minutes, the stirring rate is 55 rpm, the water content of the conditioned linseed is 8.2%, and the temperature is 48°C; Then the flaxseed at 48°C is conveyed into a twin-screw press for pressing to obtain pressed cake and pressed crude oil; then the pressed cake is directly expanded by an extruder, and a small amount of steam is introduced during expansion, and the temperature of the expanded outlet is controlled at 103°C. The water content of the material after cooling is 7.8%. Put the puffed material into a closed container, pass ...

Embodiment 3

[0054] Select fresh and mature perilla seeds to clean and remove impurities, and then use far infrared treatment for 8 minutes under the condition of 0.05 MPa, in which the power density is 3w / g, and the irradiation distance is 170mm; The micro-expansion was performed for 4 minutes, and the temperature of the expanded perilla seeds was 110°C, and the water content was 5.5%. Put the perilla seeds in a closed container, pour in atomized water at 25°C while stirring, and continue stirring for 50 minutes at a stirring rate of 30 rpm. The water content of the conditioned perilla seeds is 9%, and the temperature is 48 ℃; then the perilla seeds at 48 ℃ are conveyed into a single-screw press for pressing to obtain pressed cake and pressed crude oil; then the pressed cake is directly expanded by an extruder, and a small amount of water is introduced during the expansion, and the temperature of the expanded outlet is controlled at 115°C, the water content of the cooled material is 8.5%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com