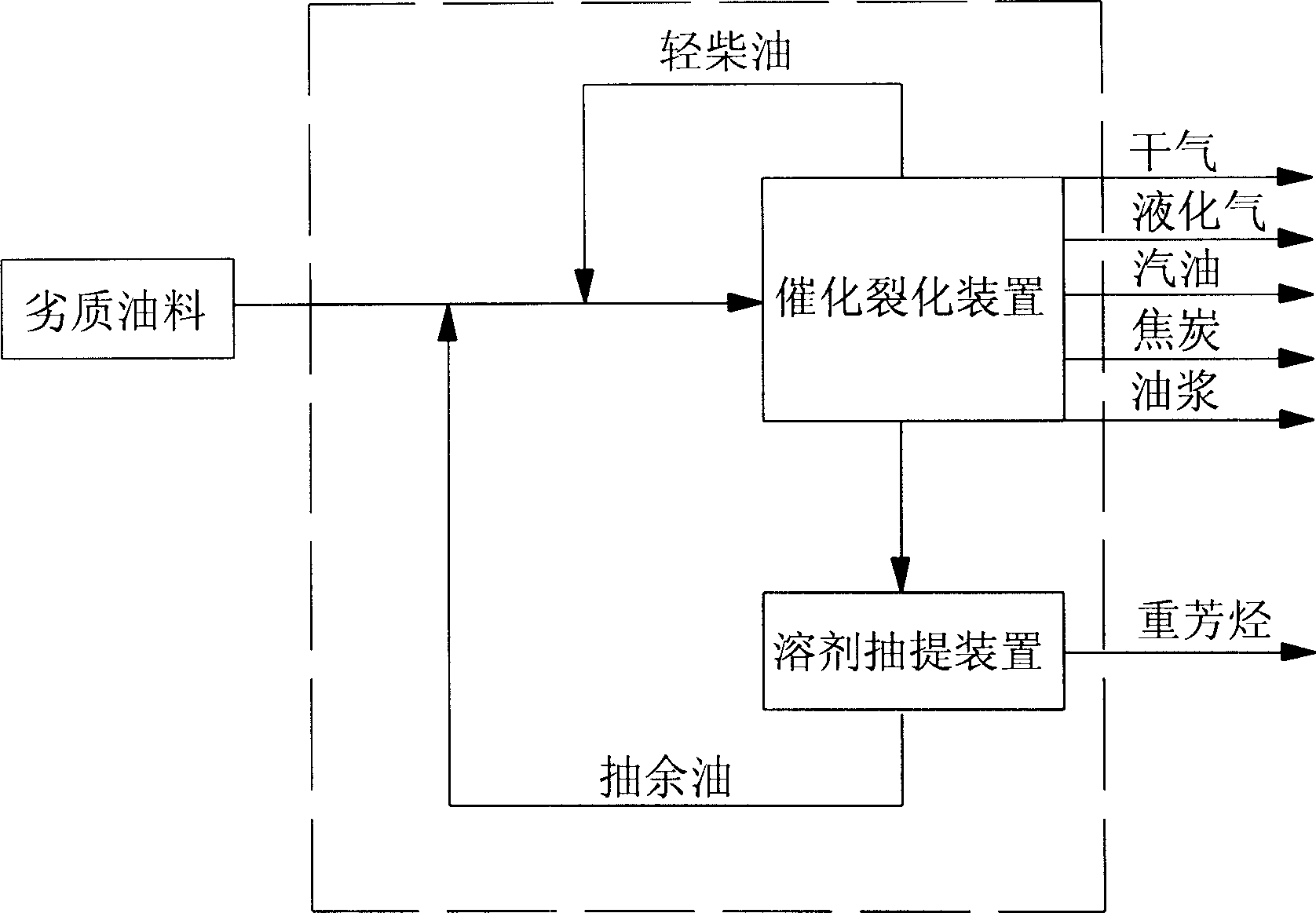

Catalyzing and cracking process of inferior oil

A technology of catalytic cracking and processing technology, which is applied in catalytic cracking, cracking, petroleum industry, etc. It can solve the problems of increased unit processing capacity and decreased coke output, and achieve the effect of reducing unit consumption and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Using the same heavy oil catalytic cracking unit and low-quality oil as in Comparative Example 1, the extraction unit used the newly-built 40,000 tons / year heavy diesel oil aromatics extraction unit of the Petrochemical Group Company, and the solvent extraction was carried out in a rotary tower. The structure of the tower is the same as that of the common rotary table tower for furfural extraction of lubricating oil. The extraction adopts double solvent extraction, the first solvent is wet furfural with water content of 5-8%, and the second solvent is solvent oil with boiling point range between 90-120°C and aromatic content <5%. The heavy diesel oil enters from the bottom of the middle part of the rotary table, the wet furfural enters from the top of the tower, and the second solvent enters from the bottom of the tower. Heavy diesel oil: wet furfural: solvent oil (weight ratio)=1: 0.8: 0.5. Extraction temperature: 80°C at the top of the tower, 65°C at the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com