Scanning type nozzle atomizing field for drop grain size and concentration space distribution analyzer

A technology of droplet size and spatial distribution, which is used in particle size analysis, particle and sedimentation analysis, and material analysis. problems such as large errors, to achieve the effect of short experimental measurement cycle, easy automation, and large sampling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

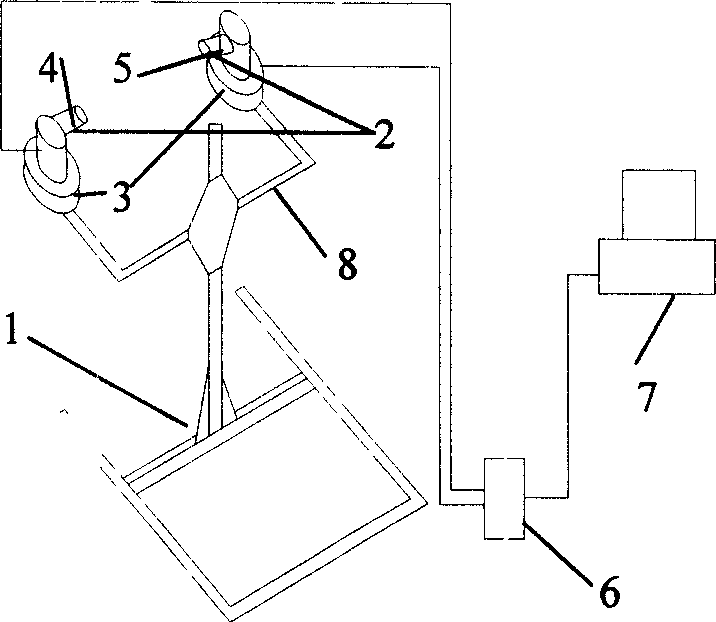

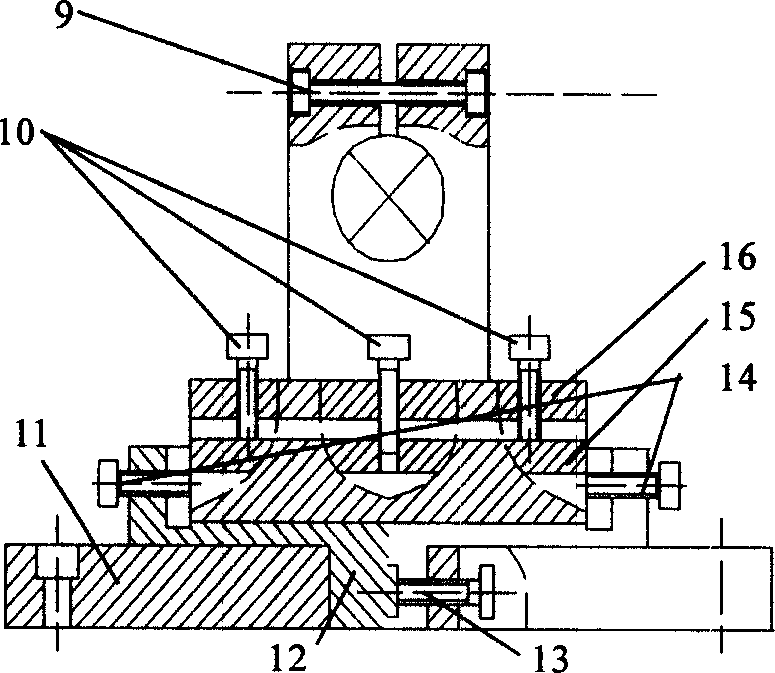

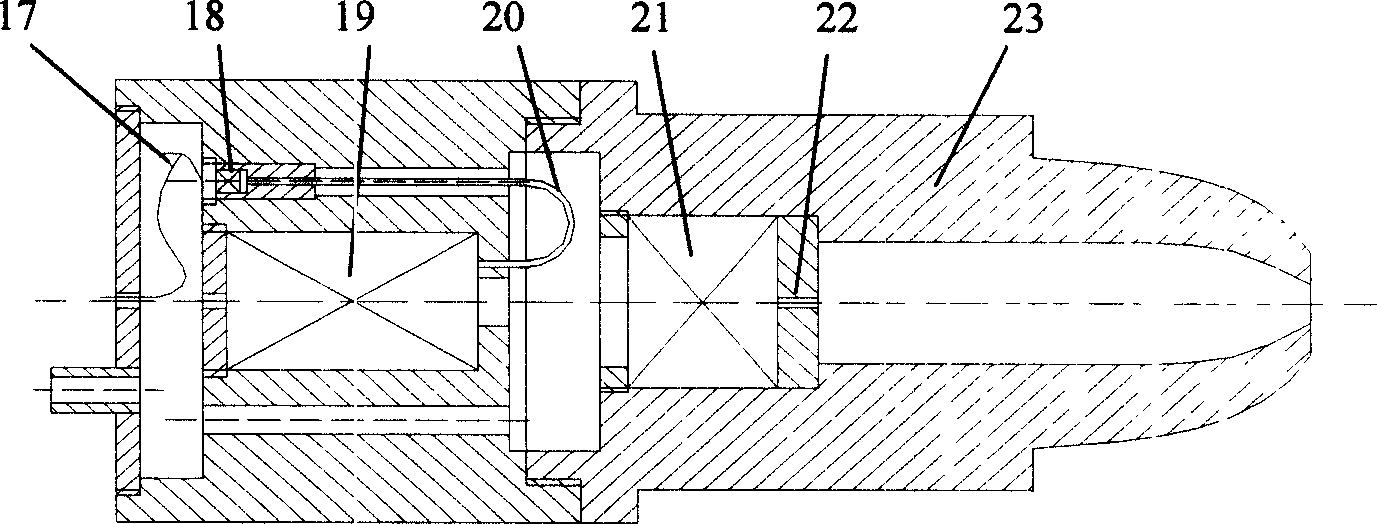

[0018] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention includes: programmable control guide rail frame 1, particle size and concentration optical sensor 2, two fine-tuning supports 3, A / D converter 6, computer 7, particle size and concentration optical sensor 2 are separated The structure is composed of a transmitting end 4 and a receiving end 5, which are respectively arranged on two fine-tuning supports 3, and the two fine-tuning supports 3 are respectively fixed on the programmable control rail frame 1, and the transmitting end 4 and the receiving end 5 collect The photoelectric signal of the A / D converter is connected to the input end of the A / D converter 6 through the wire, and the digital signal output by the A / D converter is transmitted to the computer 7 through the wire.

[0019] The programmable control rail frame 1 has a U-shaped cantilever beam 8, and the front end of the U-shaped cantilever beam 2 is respectively provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com