Micro jet flow cooling system for electronic device

A technology for electronic devices and cooling systems, applied in the cooling of instruments, electrical solid devices, electrical components, etc., can solve the problem that the cooling method of large heat flux cannot reach the ideal, and achieve the effect of high heat transfer coefficient and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

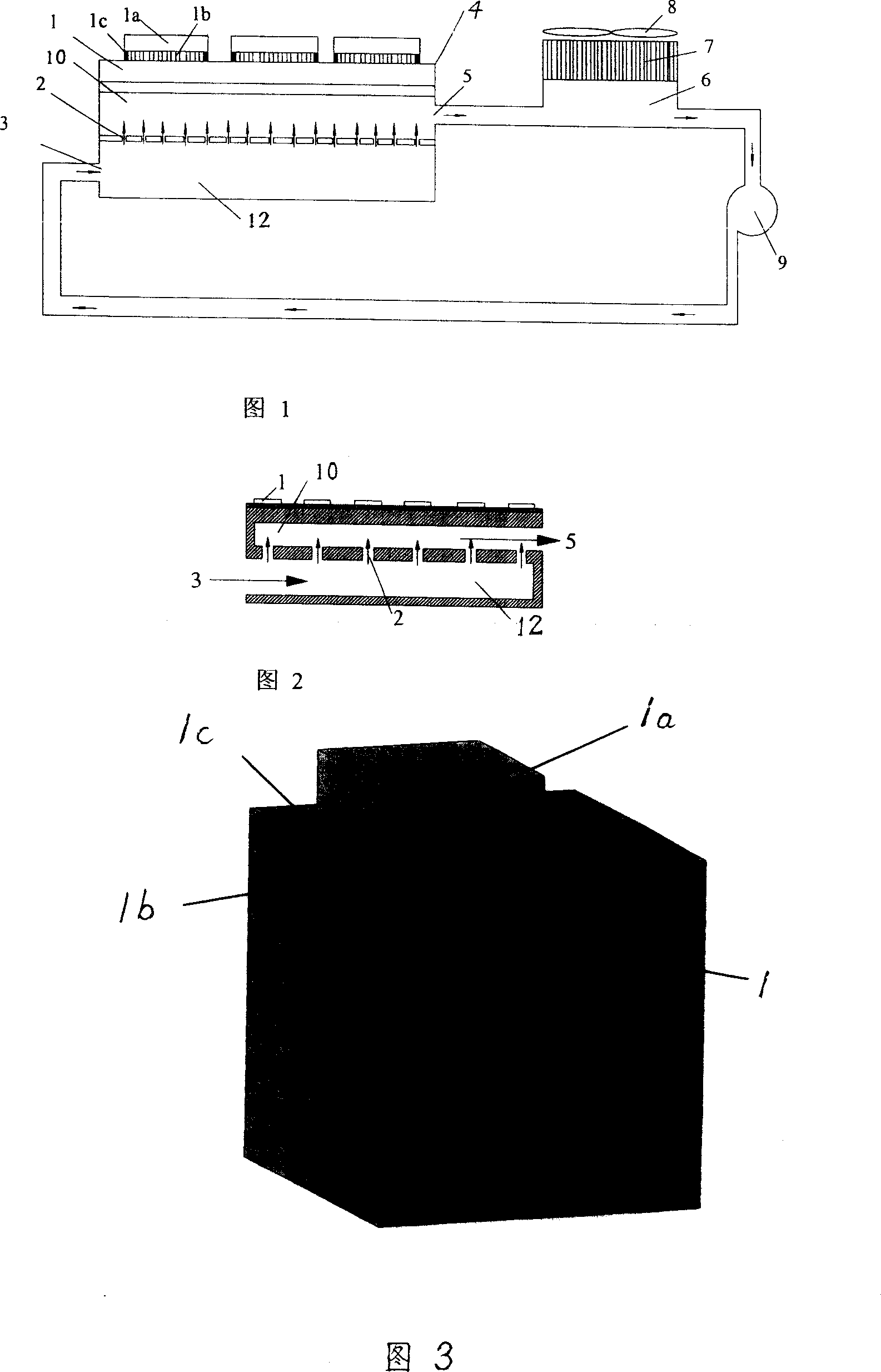

[0014] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0015] Referring to Fig. 1, Fig. 2, Fig. 3, the base 1 of the electronic components and parts of the present embodiment is a computer chip CPU1a, and the computer chip CPU 1a is installed together with the base 1 of the electronic device by connecting the welding post 1b, and the computer chip CPU 1a With thermal diffusion column 1c. The lower surface of the base 1 of the electronic components is tightly mounted on the shell of the micro jet 4, and the micro jet 4 is made of carbon nanotubes, high thermal conductivity metal, diamond and other high thermal conductivity materials. A heat conduction paste is added between the outer surface of the micro jet and the lower surface of the base of the CPU to increase the heat conduction effect and reduce the heat resistance. The micro-jet flow device 4 is provided with two cavities, the upper cavity 10 and the lowe...

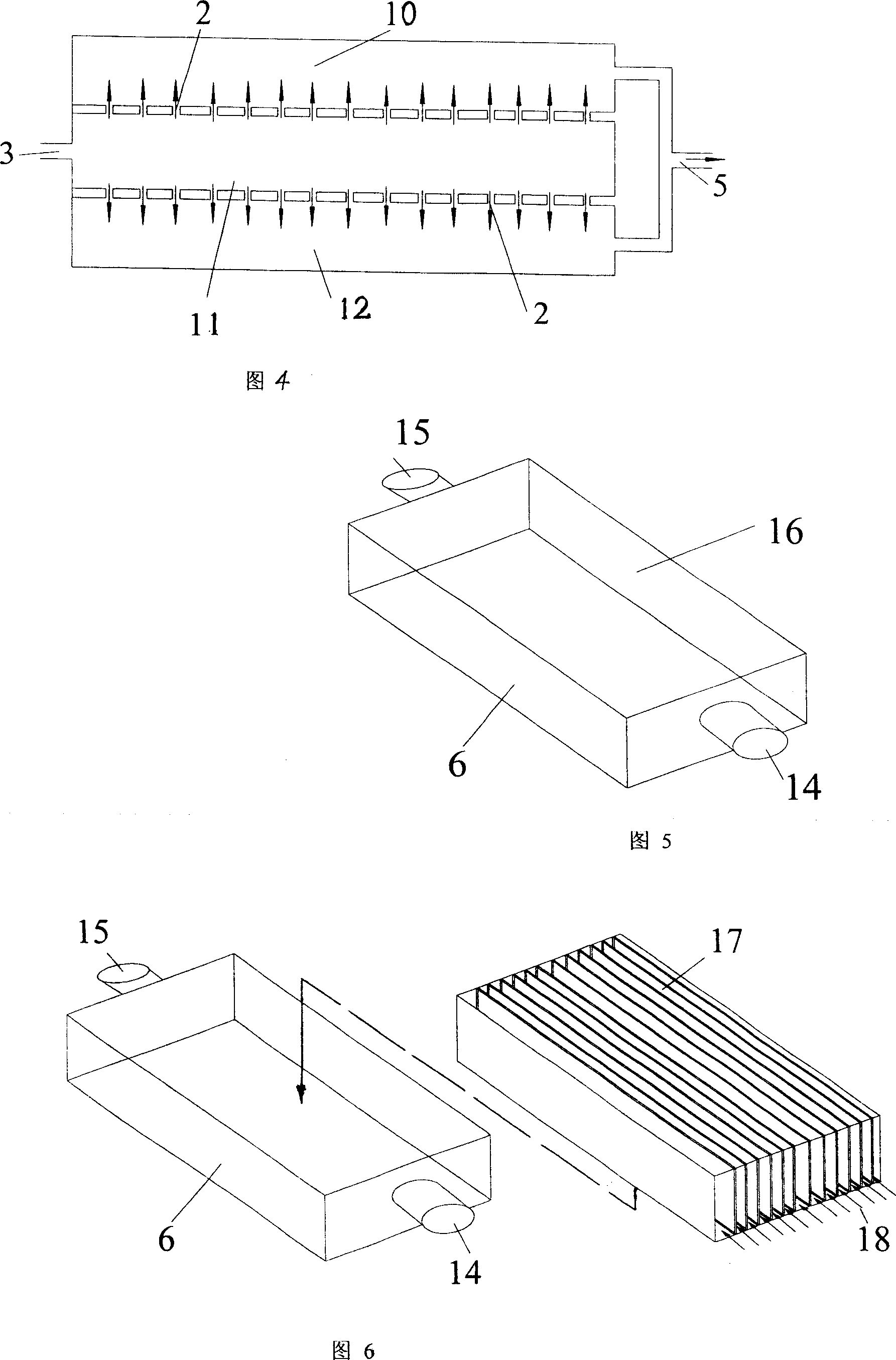

Embodiment 2

[0019] Embodiment 2 is the same as Embodiment 1, except that Embodiment 1 adopts the middle of the chamber of the micro-jet fluidizer to be divided into upper and lower chambers 10, 12 by a partition plate 2 with a plurality of micro-nozzles 21. . And embodiment 2 is divided into upper, middle and lower three cavities 10, 11, 12 by two partitions 2 with a plurality of micro nozzles. See Figure 4. Liquid or gas flows in from the cooling medium inlet 3 of the micro jet, and the liquid or gas enters the middle cavity 11 of the micro jet cavity, and under the action of pressure, the liquid or gas forms a jet at the micro nozzles 21 on both sides , the inner side of the contact surface of the micro jet that is closely connected to the lower surface of the base 1 of the impact electronic device, the liquid or gas after heat exchange flows out from the lower cavity 12 and the upper cavity 10 respectively and merges in the micro jet Cooling medium outlet 5, re-enter the main pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com