Oscillation apparatus, jet stream generator and electronic equipment and vibration device manufacture method

A vibrating device and vibrating element technology, which can be applied to electric solid devices, electrical components, semiconductor devices, etc., can solve problems such as the inability of the gas to vibrate effectively and the deflection of the vibrating plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0209] The following is a description of embodiments of the present invention with reference to the accompanying drawings.

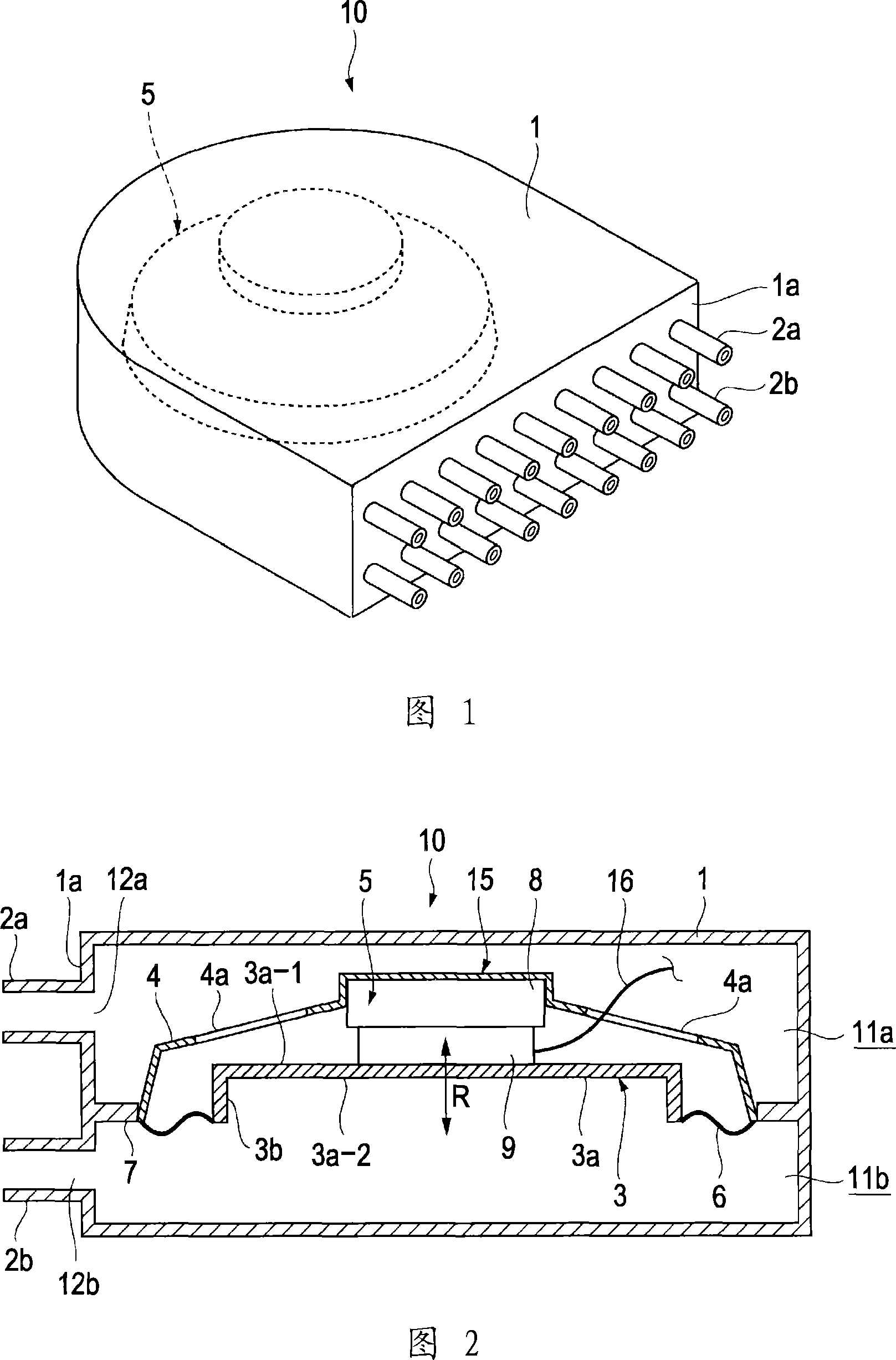

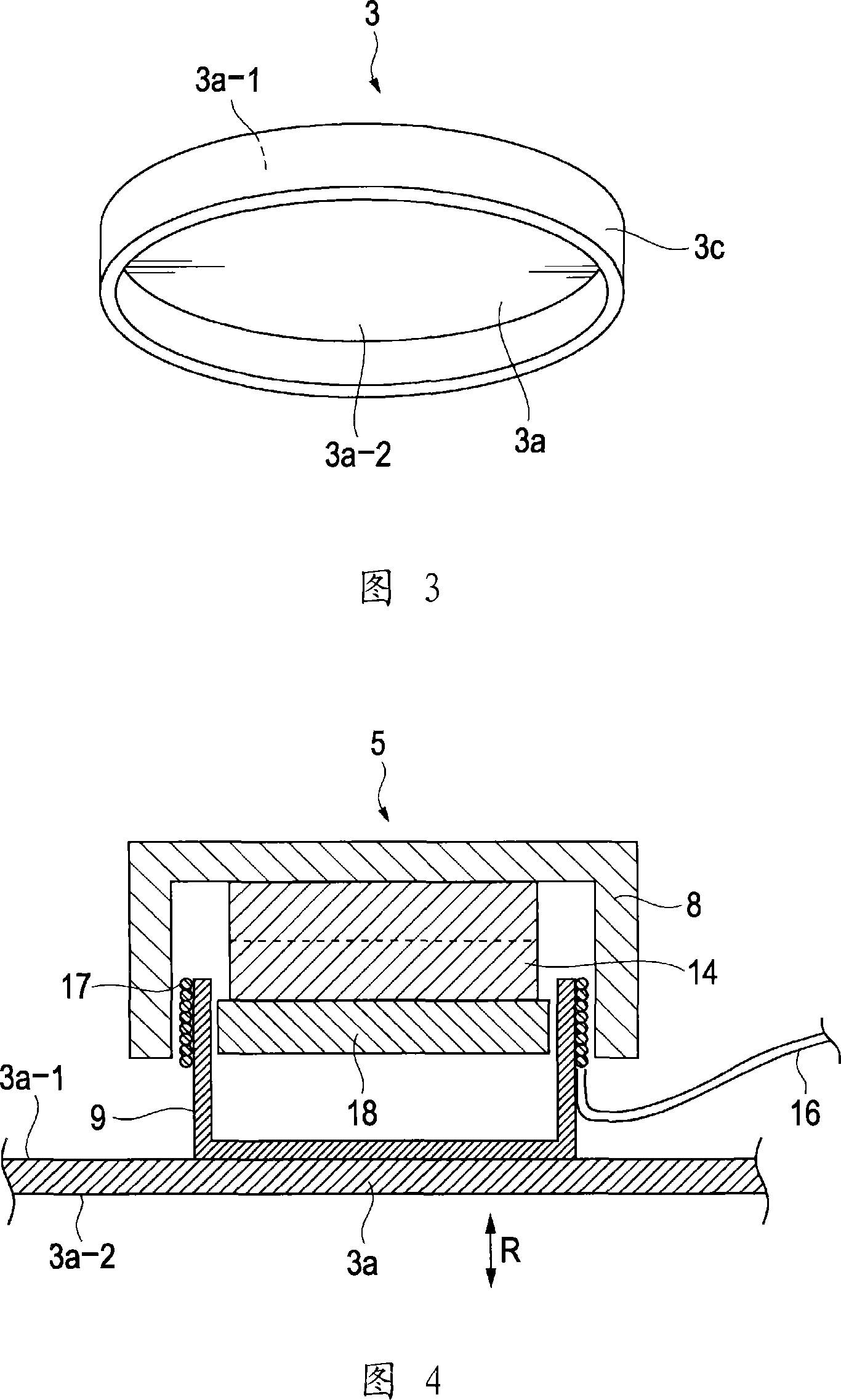

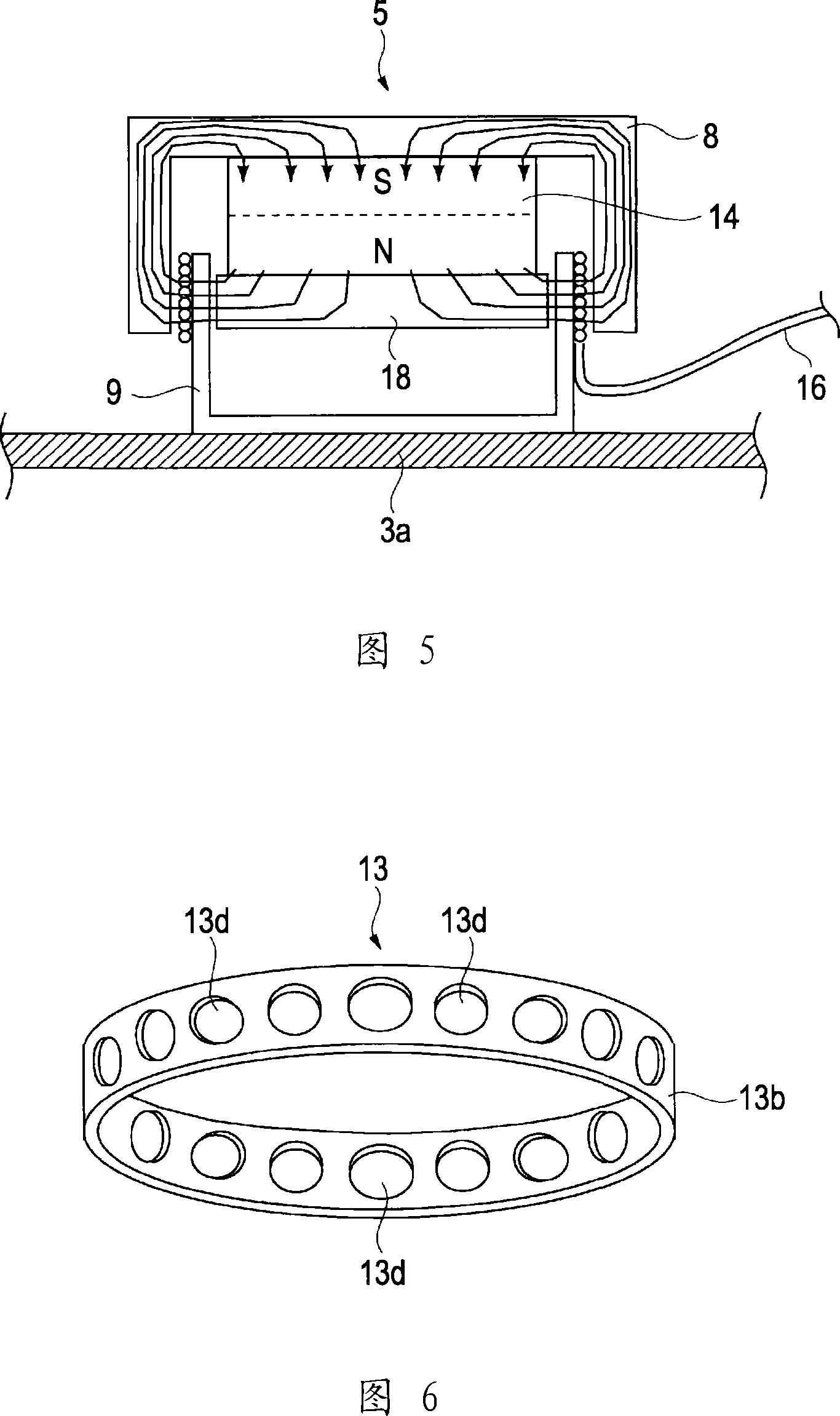

[0210] FIG. 1 is a perspective view illustrating a jet flow generating device according to an embodiment of the present invention, and FIG. 2 is a cross-sectional view of the jet flow generating device shown in FIG. 1 .

[0211] The jet flow generating device 10 has a housing 1 whose rear portion has a cylindrical shape, and a vibrating device provided in the housing 1 . A plurality of nozzles 2a and 2b are arranged on the front face 1a of the housing 1. As shown in FIG. As shown in FIG. 2 , the inside of the casing 1 is divided into an upper chamber 11 a and a lower chamber 11 b by a vibrating device 15 attached by means of an attachment portion 7 . On the front face 1a of the housing 1 where the nozzles 2a and 2b are provided, openings 12a and 12b are formed at positions corresponding to the nozzles 2a and 2b. Thus, the upper chamber 11a and the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanent flux density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com