System and method for thermal management using distributed synthetic jet actuators

a synthetic jet actuator and actuator technology, applied in the field of thermal management technology, can solve the problems of electromagnetic interference and noise generated by the magnetic-based fan motor, the relative inefficiency of fans in heat removal, and the major challenge of thermal managemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

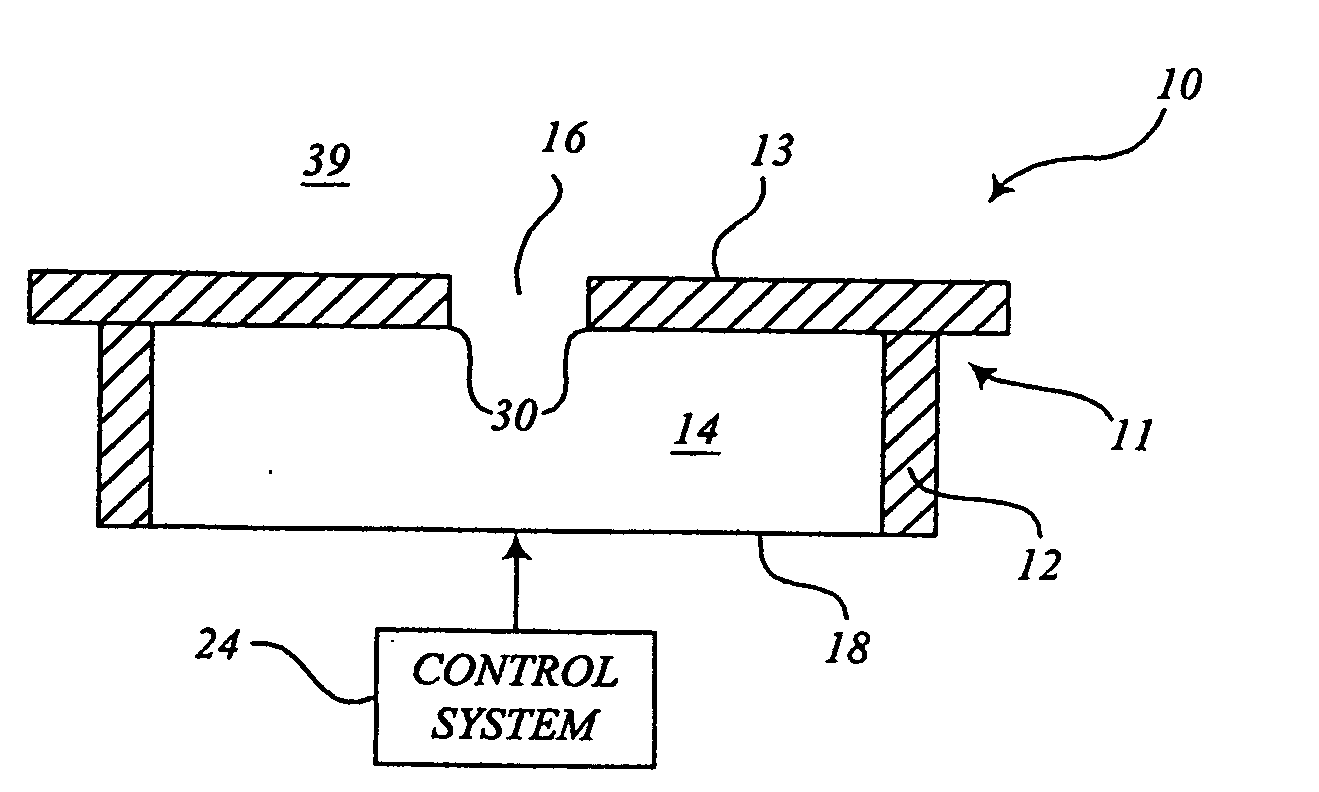

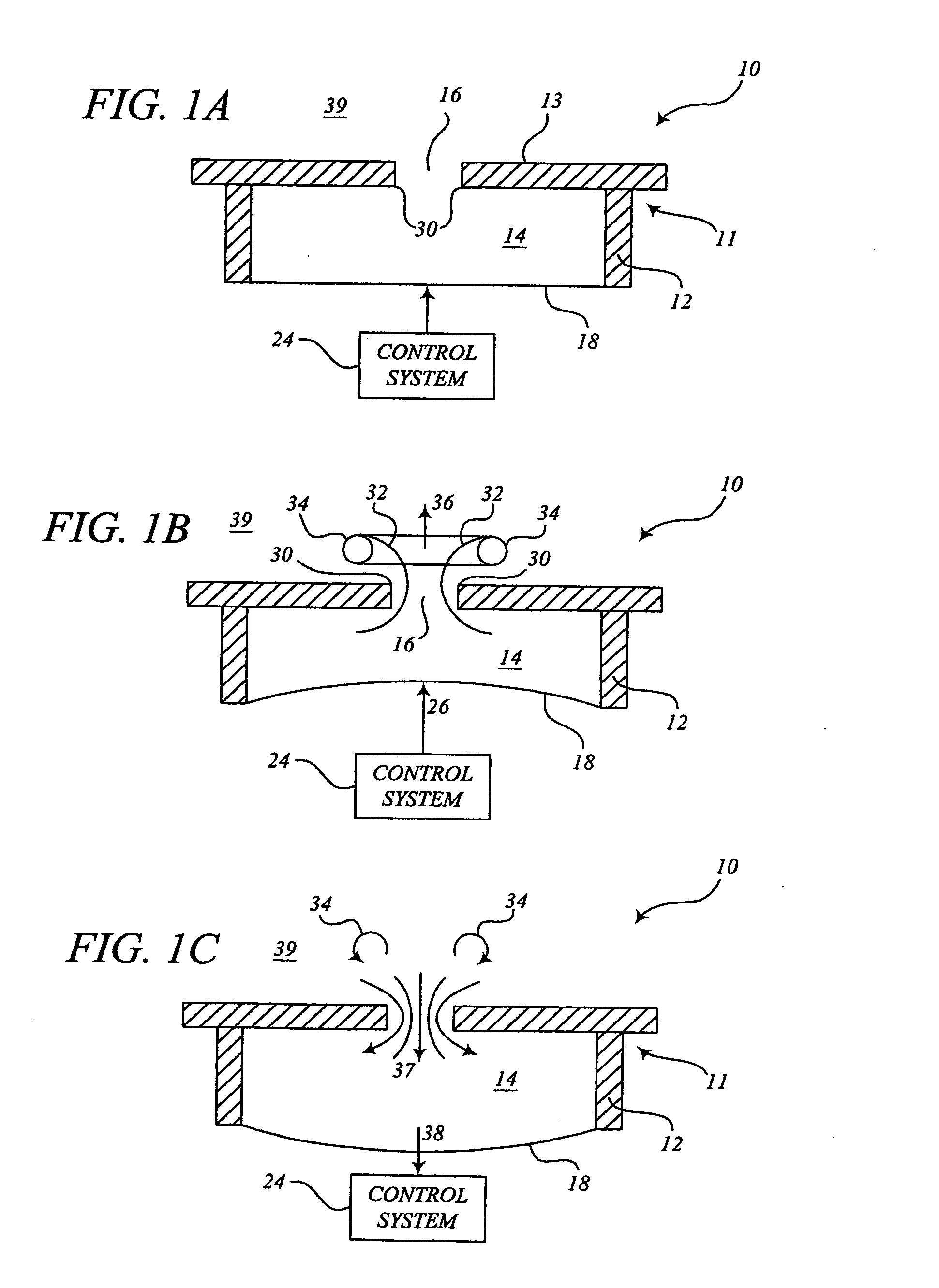

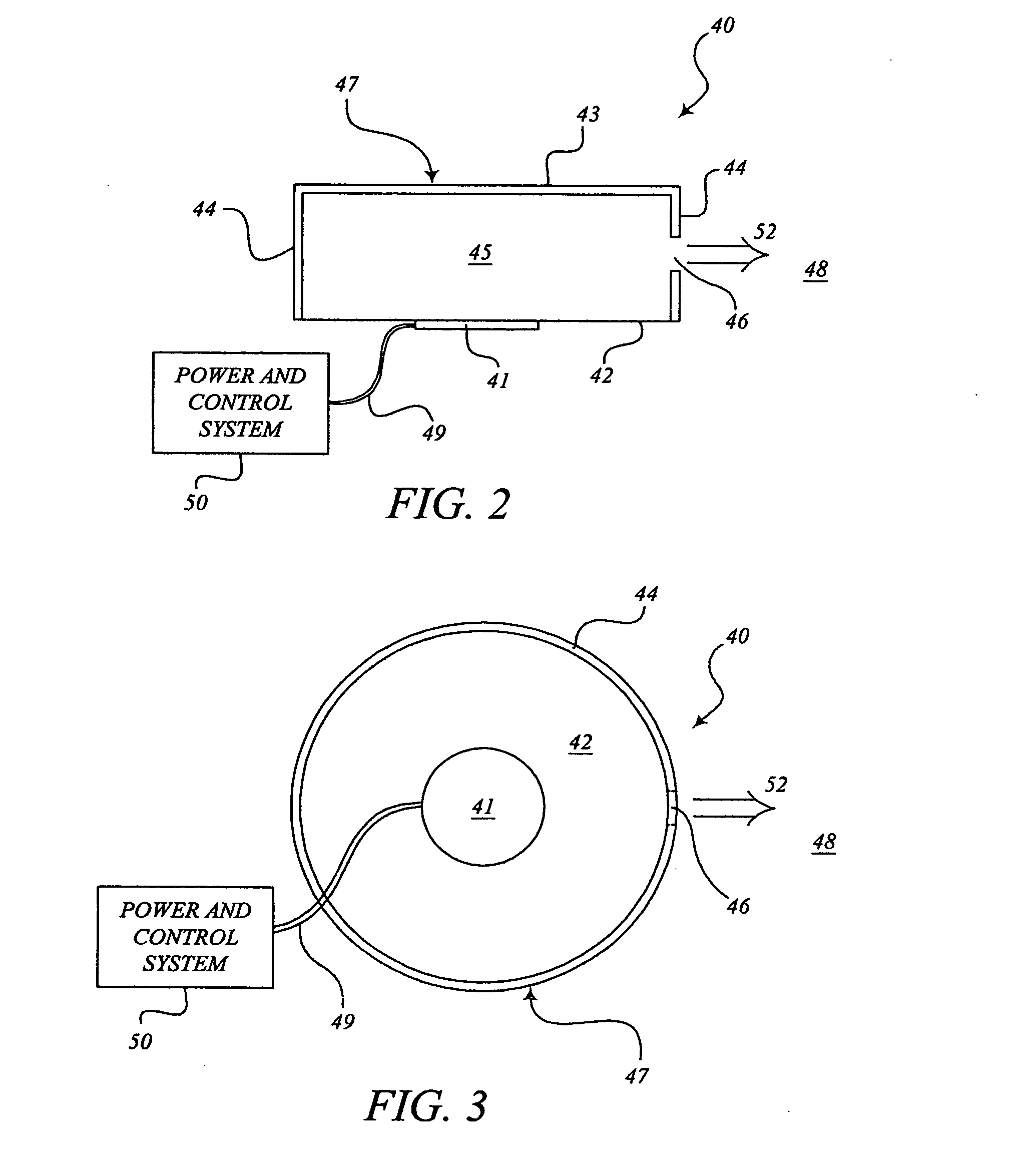

Image

Examples

first example

A. FIRST EXAMPLE

Single Actuator Device

[0054] The synthetic jet actuators 10, 40 described above can be used in a number of different embodiments. However, one specific adaptation of the synthetic jet actuators 10, 40 is for what may be referred to as distributed cooling applications. A distributed cooling application is a situation that may call for a single synthetic jet actuator to provide a cooling synthetic jet stream to multiple locations. Alternatively, a distributed cooling application may call for a synthetic jet actuator to supply cooling fluid flow to a single location that is somewhat remote from the location of the actuator. Although not limiting examples, these two examples are common distributed cooling applications.

[0055]FIG. 4A depicts one embodiment of a distributed cooling synthetic jet actuator 60. For ease of explanation, the exemplary embodiment of a distributed cooling synthetic jet actuator 60 has been designed as a modified form of the second exemplary embo...

second example

B. SECOND EXAMPLE

Multiple Actuator Device

[0070] In some implementations of a distributed cooling apparatus, it may be desirable to generate multiple synthetic jet streams. As noted above, a single synthetic jet actuator 40 may drive multiple tubes, and thereby generate multiple, distributed synthetic jet streams of fluid. This, of course, is not the only possible implementation of a multiple synthetic jet distributed cooling apparatus. Another exemplary embodiment may comprise multiple synthetic jet actuators driving multiple tubes, and thereby emitting multiple synthetic jet streams. The tubes of such an embodiment may be directed to different areas, different heat sink channels, or all to the same location.

[0071] An exemplary embodiment of a multiple actuator distributed cooling apparatus 80 is depicted in FIG. 6. This apparatus 80 generally comprises a plurality of tubes 81 emerging from a generally rectangularly cubic housing 82. The housing 82 has two “plenums”83 formed into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com