Ammonia desulfurizing process and apparatus with crystallization inside tower

An ammonia desulfurization and internal crystallization technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of high operating costs, difficult operations, and high ammonia consumption, and achieves the goal of reducing operating costs and saving investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] The treatment object is a coal-fired boiler with an evaporation capacity of 220t / h and a flue gas volume of 280,000Nm 3 / h, the coal consumption of the boiler is 32t / h, the total sulfur of coal combustion is 3%, and the exhaust gas temperature is 140°C.

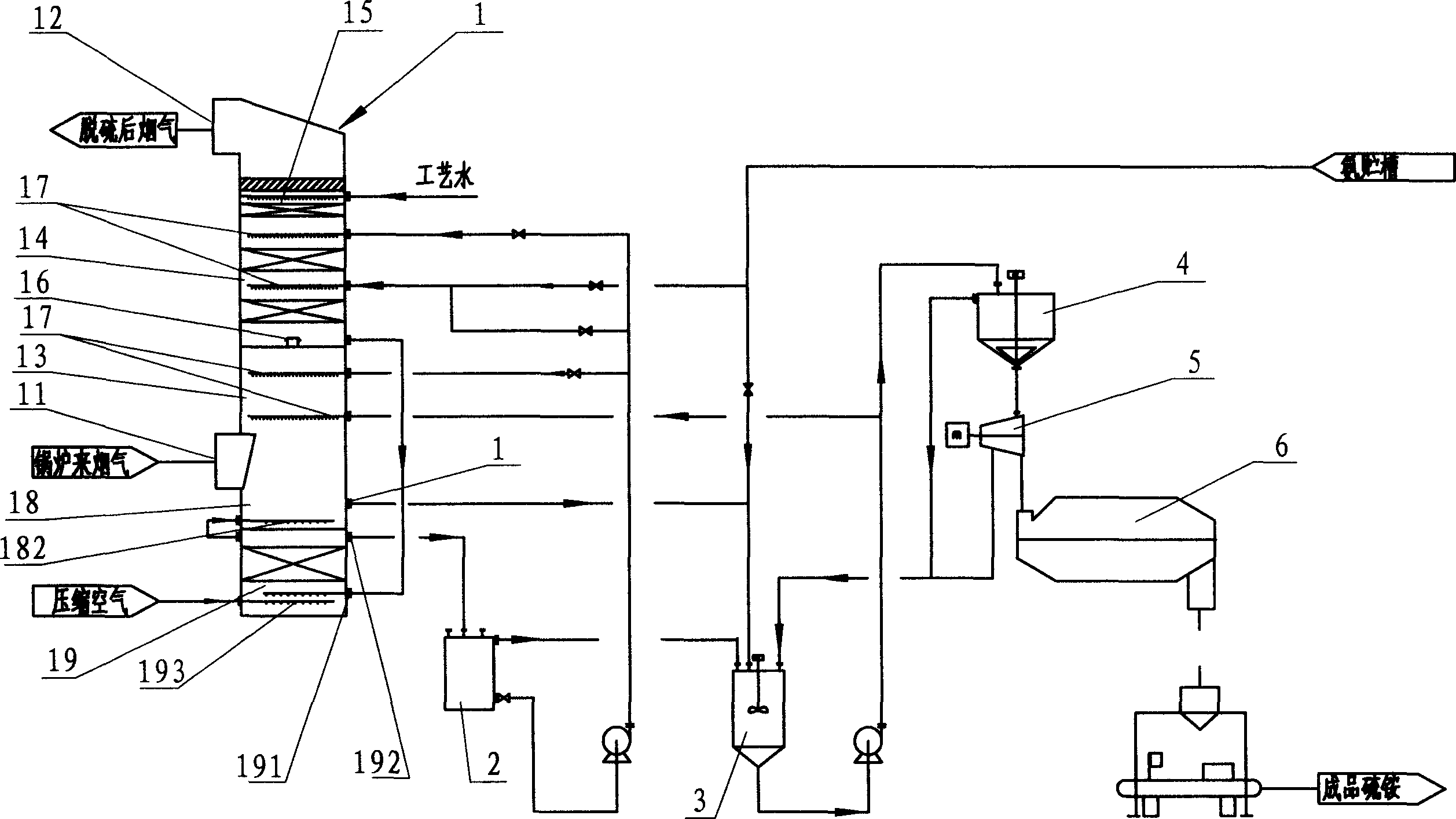

[0017] Desulfurization process and equipment such as figure 1 , The desulfurization tower of the core equipment is 39 meters high and 7.8 meters in diameter. The main absorption section packing is Y125 corrugated packing. Above the smoke inlet of the tower is the cooling absorption section, and the upper layer of the cooling absorption section (1.5 meters away from the partition plate of the cooling absorption section and the main absorption section) is a layer of low-concentration absorption liquid replenishment liquid spray layer (set up 9 nozzles for blocking). ; The lower layer of the cooling absorption section (3.5 meters away from the partition plate of the cooling absorption section and the main absorption sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com