Steaming oven having multiple operating modes

An operating mode and a technology of steaming ovens, applied in the field of steaming ovens, can solve the problems of single processing mode and low processing efficiency of steaming ovens, and achieve the effects of convenient adjustment, high processing efficiency, and various operating modes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

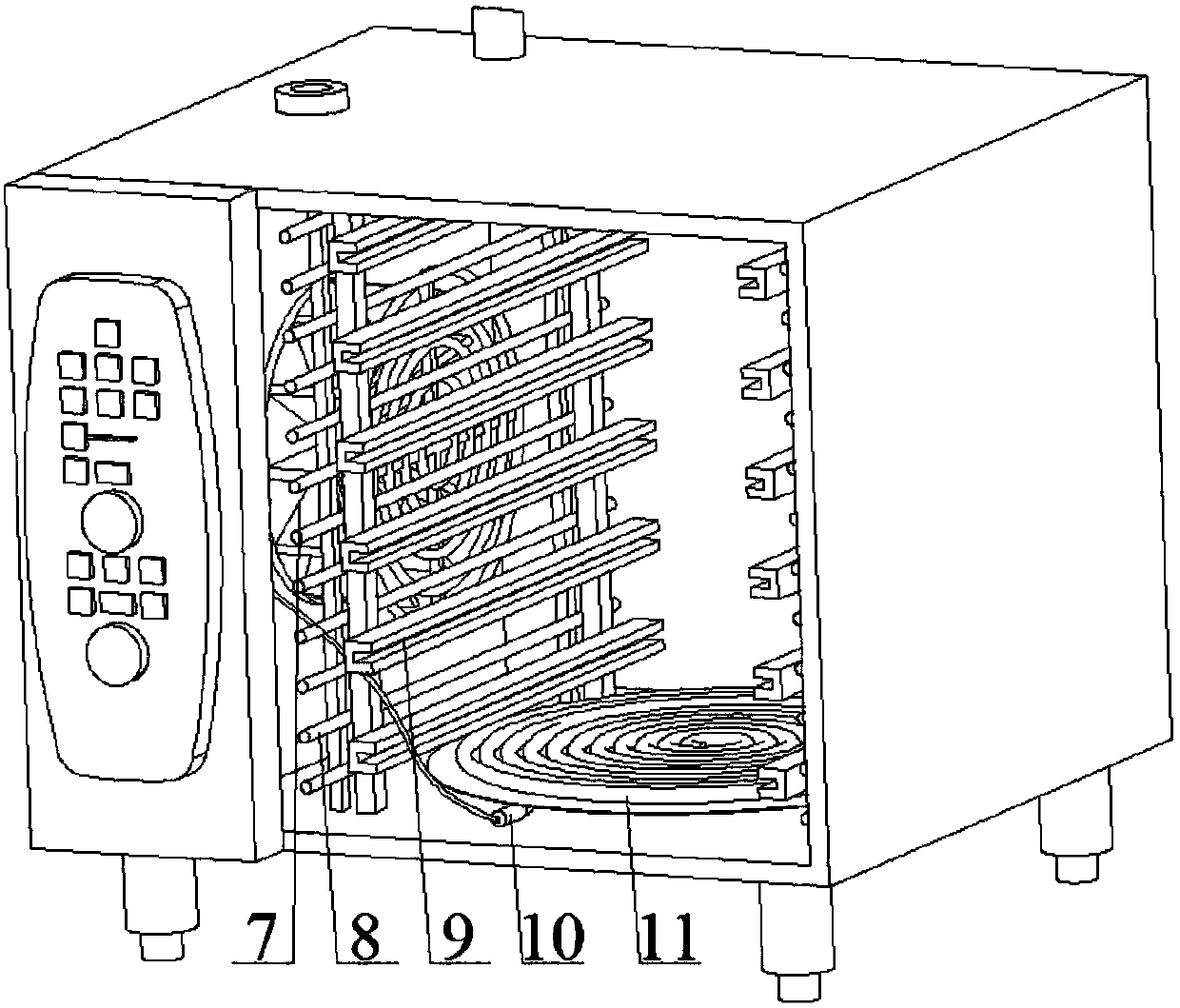

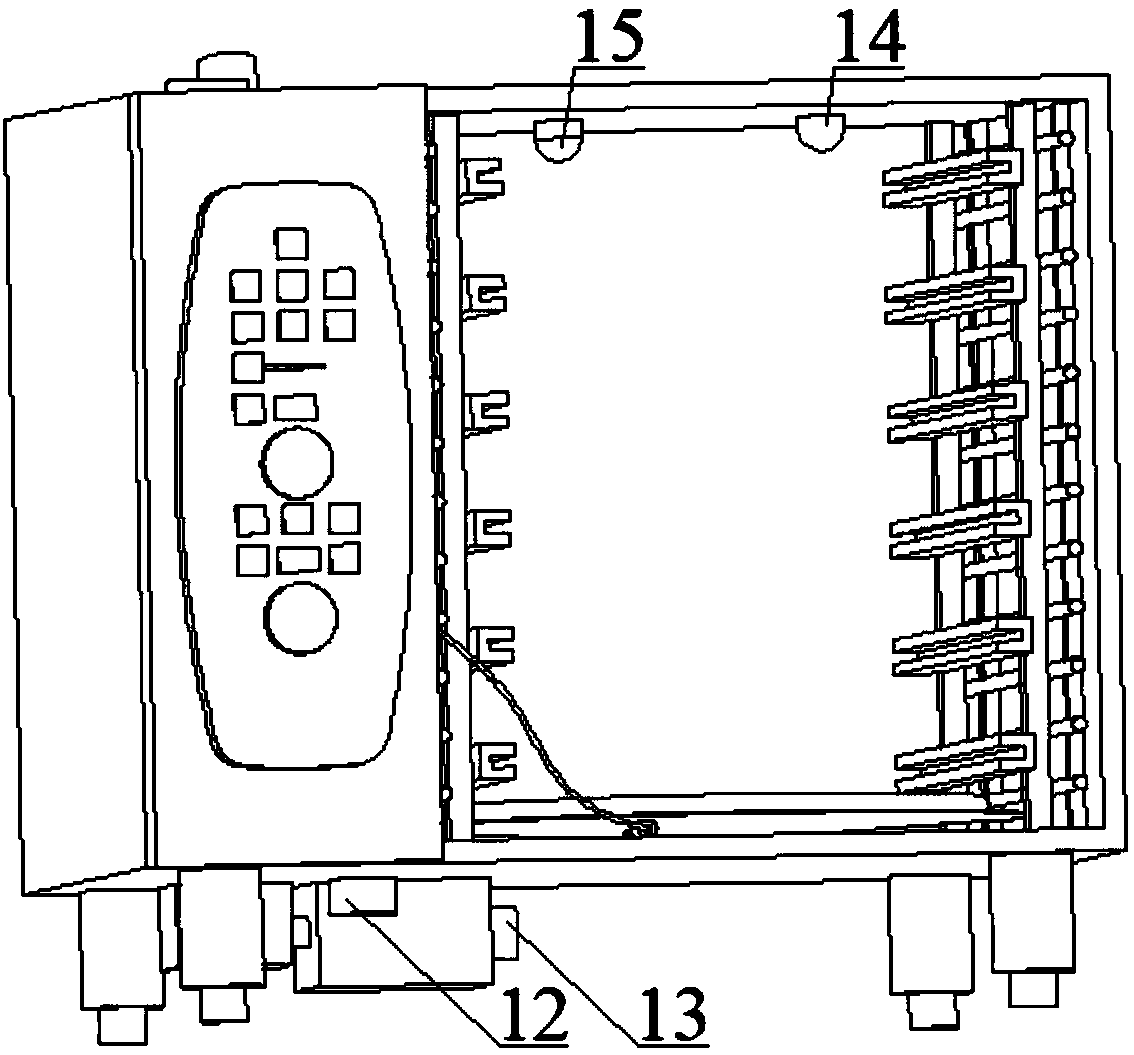

[0047] Steam operation mode: put the food to be processed into the steaming chamber, press the steam function key 17, select the steam operation mode; press the steaming chamber temperature selection switch 20, select the appropriate steam temperature; press the humidity setting key 29, select Appropriate humidity in the steaming chamber; press the cooking time setting key 26 to select an appropriate processing time.

[0048] Press the start-stop work key 21, the central processing unit sends a control command to the controller, the controller controls the steam generator to emit steam, controls the spiral fan 7 to provide low-intensity circulating air, and controls the timer to start counting; the control humidity adjustment detection module according to Real-time humidification or dehumidification in the steaming and baking room, which can be used for steaming and processing of pasta.

Embodiment 2

[0050] Hot air operation mode: put the food to be processed into the steaming chamber, press the hot air function key 30, select the hot air operation mode; press the steaming chamber temperature selection switch 20, select the appropriate heating temperature; press the humidity setting key 29, select Appropriate humidity in the steaming chamber; press the cooking time setting key 26 to select an appropriate heating time.

[0051] Press the start-stop work key 21, the central processing unit sends a control command to the controller, the controller controls the heating tube 8 to start heating, controls the spiral fan 7 to provide high-intensity circulating air, and controls the timer to start counting; the control humidity adjustment detection module according to Real-time humidification or dehumidification in the steaming and baking room, which can be used for baking, grilling, frying, and bread-baked food processing.

Embodiment 3

[0053] Steaming operation mode: put the food to be processed into the steaming chamber, press the steaming function key 18, select the steaming operation mode; press the steaming chamber temperature selection switch 20, select the appropriate heating temperature; press the humidity setting key 29. Select an appropriate humidity in the steaming chamber; press the cooking time setting key 26 to select an appropriate heating time.

[0054] Press the start-stop working key 21, the central processing unit sends a control command to the controller, the controller controls the heating tube 8 to start heating, the controller controls the steam generator to emit steam, controls the spiral fan 7 to provide low-intensity circulating air, and controls the timer Start timing; control the humidity adjustment detection module to humidify or dehumidify according to the real-time situation in the steaming and baking room, and can perform baking and frying food processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com