Modified grapheme preparation method

A technology of graphene and graphene film, which is applied in the field of graphene to achieve the effect of increased electrical conductivity, low cost, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

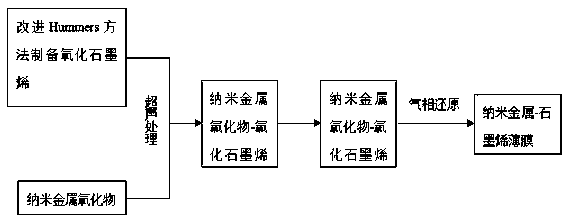

[0034] A kind of preparation method of modified graphene, such as figure 1 shown, including the following steps:

[0035] S1. Preparation of graphene oxide:

[0036] S11. Low-temperature stage: add flake graphite and sodium nitrate washed with dilute hydrochloric acid and deionized water into concentrated sulfuric acid, mix the three evenly through ultrasonic treatment, place them in an ice bath, and then slowly add permanganate to it Potassium, the solution turns dark green;

[0037] The mass ratio of described flake graphite, sodium nitrate, concentrated sulfuric acid and potassium permanganate is 1:1:50:6;

[0038] S12. Medium temperature stage: transfer the solution obtained in step S11 into a 50°C water bath and stir for 7 hours, the solution turns brown, slowly add deionized water, then raise the temperature of the water bath to 70°C, react for 45min, and then add hydrogen peroxide to The solution turned golden yellow, and water was added after 20 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com