Method and device for preparing micro-bubbles

A technology of microbubbles and metals, which is applied in the fields of chemical engineering and biomedical engineering, can solve the problems of microbubble coating thickness unevenness, short retention time, and capsule rupture, and achieves good size distribution and easy promotion and implementation. Good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The device of the present invention will be specifically described below with the accompanying drawings, the purpose of which is to better understand the content of the present invention, but the scope of protection of the present invention is not limited to the following examples.

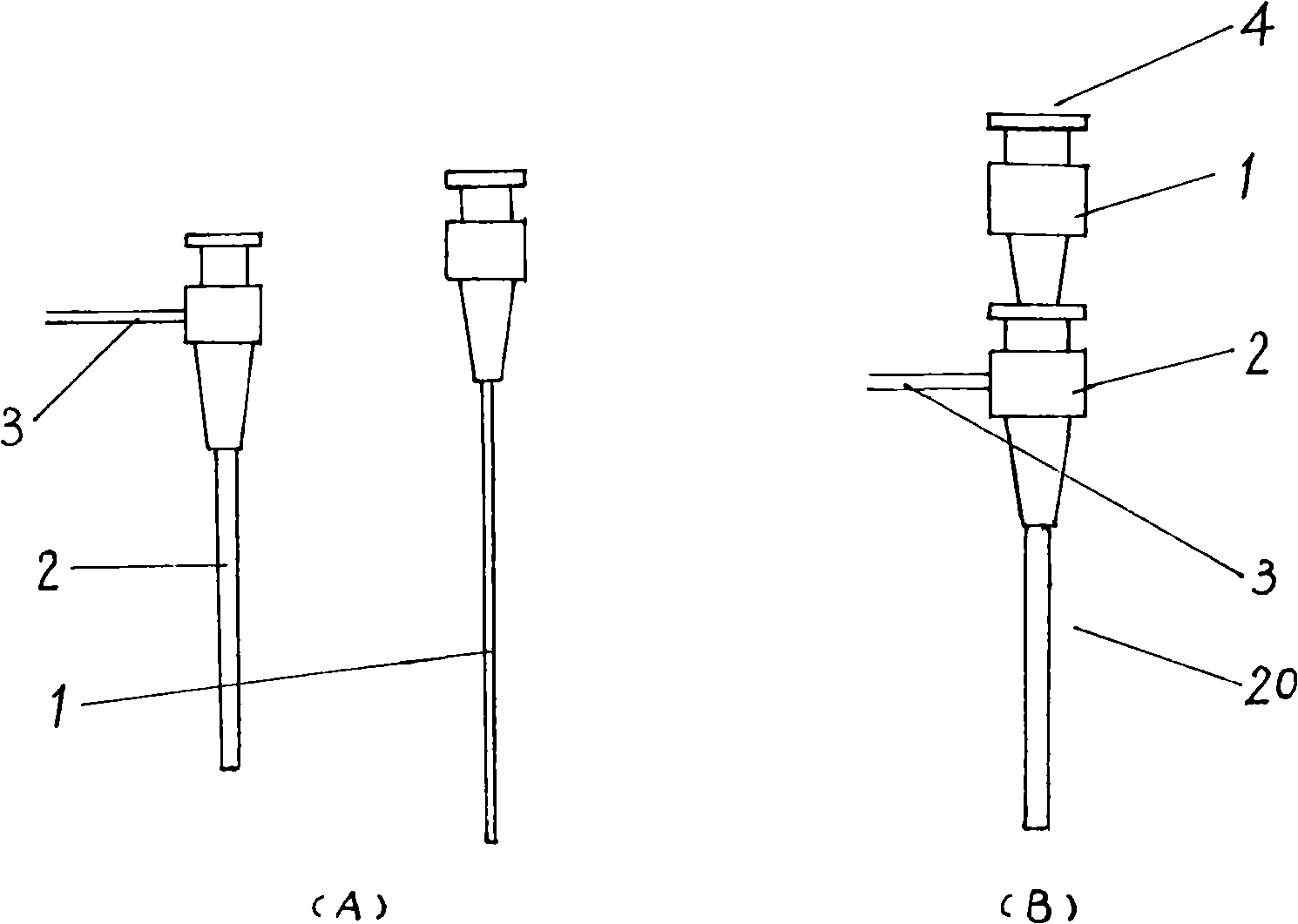

[0042] See attached figure 1 .

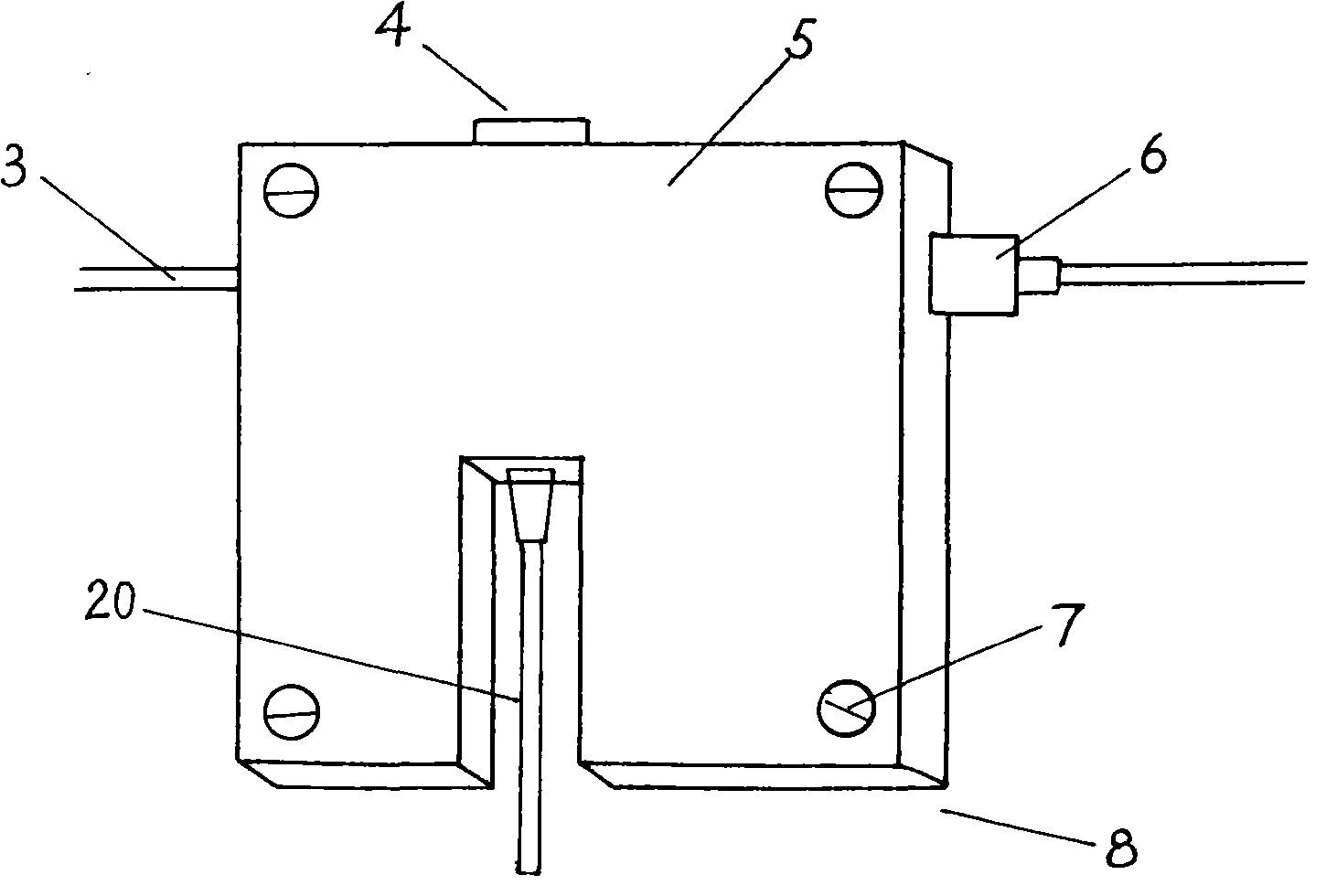

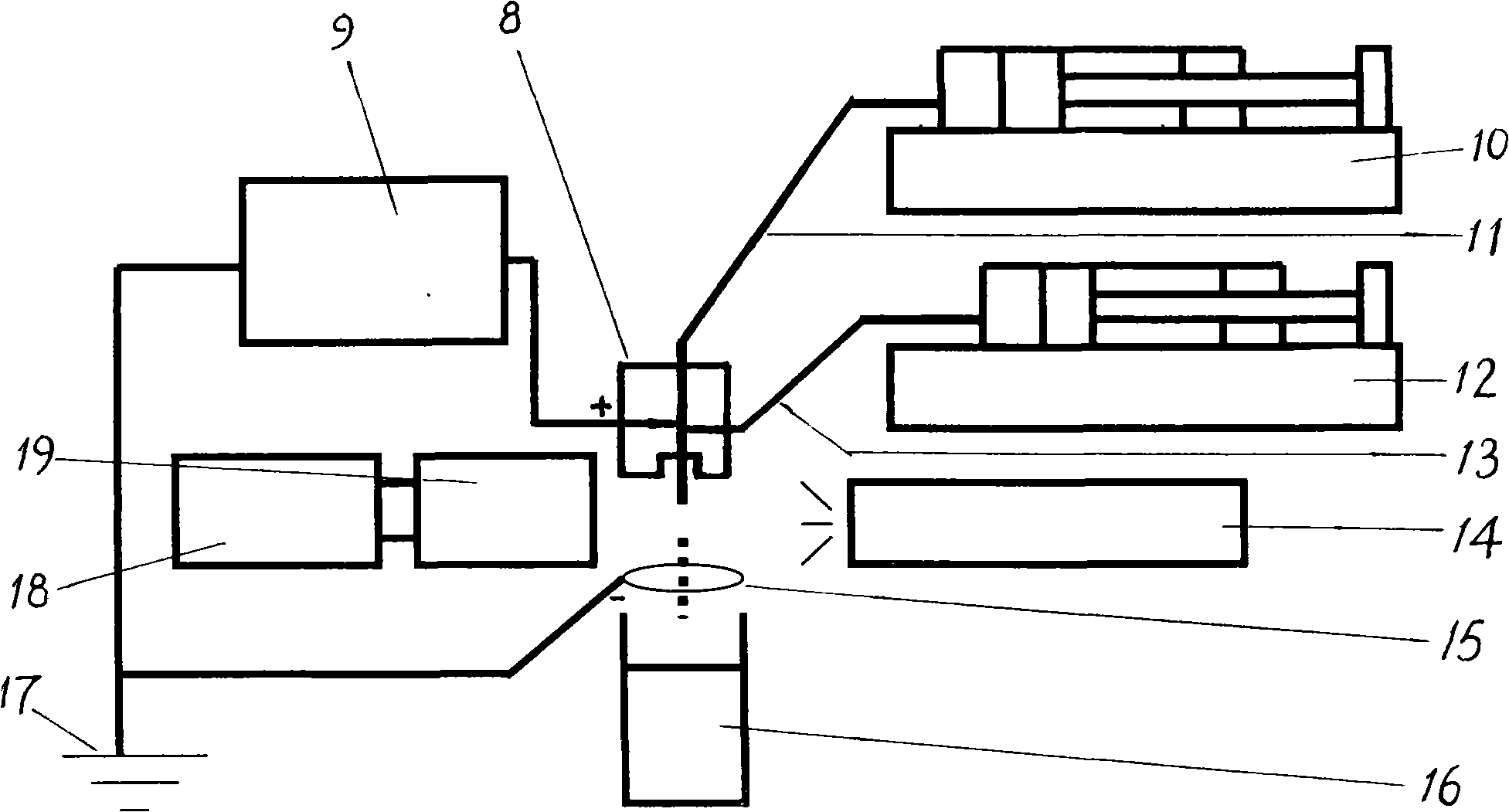

[0043] A device for preparing microbubbles. The inner needle 1 and the outer needle 2 are connected by screws to form a coaxial double-needle metal capillary 20. The inner needle 1 and the outer needle 2 adopt stainless steel needle tubes with a diameter of 200 μm to 1000 μm. The inner needle The needle tube of 1 is thinner and longer than the needle tube of the outer needle 2, and the needle seat of the outer needle 2 is provided with a connecting tube 3; the inner needle 1 is sleeved in the needle tube of the outer needle 2, and the needle seat hole of the inner needle 1 becomes the injection port 4 , the outer needle 2 is introduced into the liquid throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com