Preparation method of polymer/graphene nano composite material

A nano-composite material and graphene technology are applied in the field of preparation of polymer/graphene nano-composite materials, which can solve the problems of high cost, large consumption of organic solvents, large pollution, etc., and achieve the improvement of electrical conductivity and thermal stability. Simple and easy to use, the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a kind of preparation method of polymer / graphene nano composite material, comprises the following steps:

[0036] a) The first mass part polymer and graphene are fully mixed in an organic solvent, and after removing the organic solvent, a polymer / graphene master batch is obtained, and the graphene accounts for the first mass part polymer and graphite The mass percentage of the total amount of alkenes is 1% to 50%;

[0037] b) melt-blending the polymer / graphene masterbatch with the second mass part of polymer to obtain a polymer / graphene nanocomposite material.

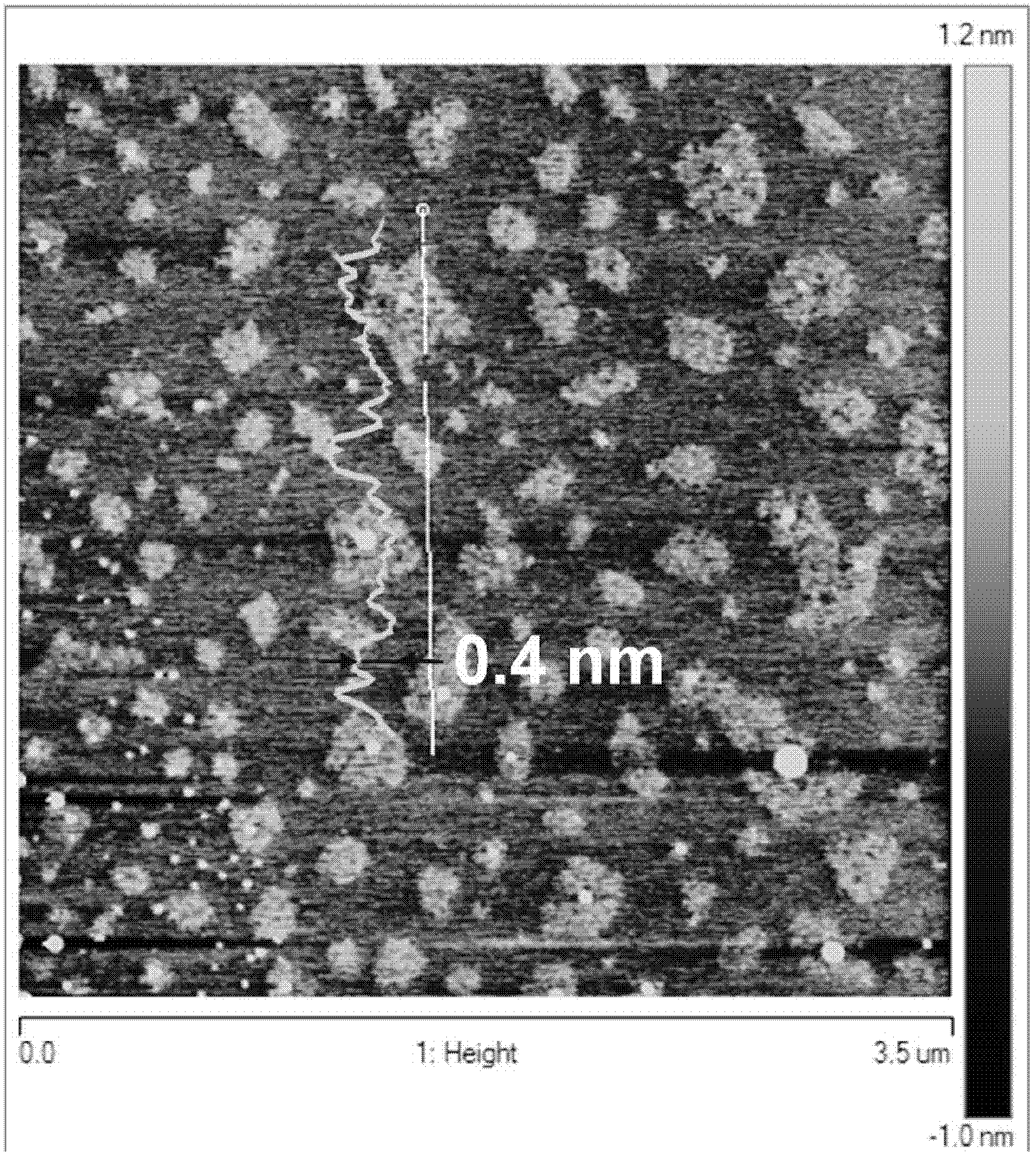

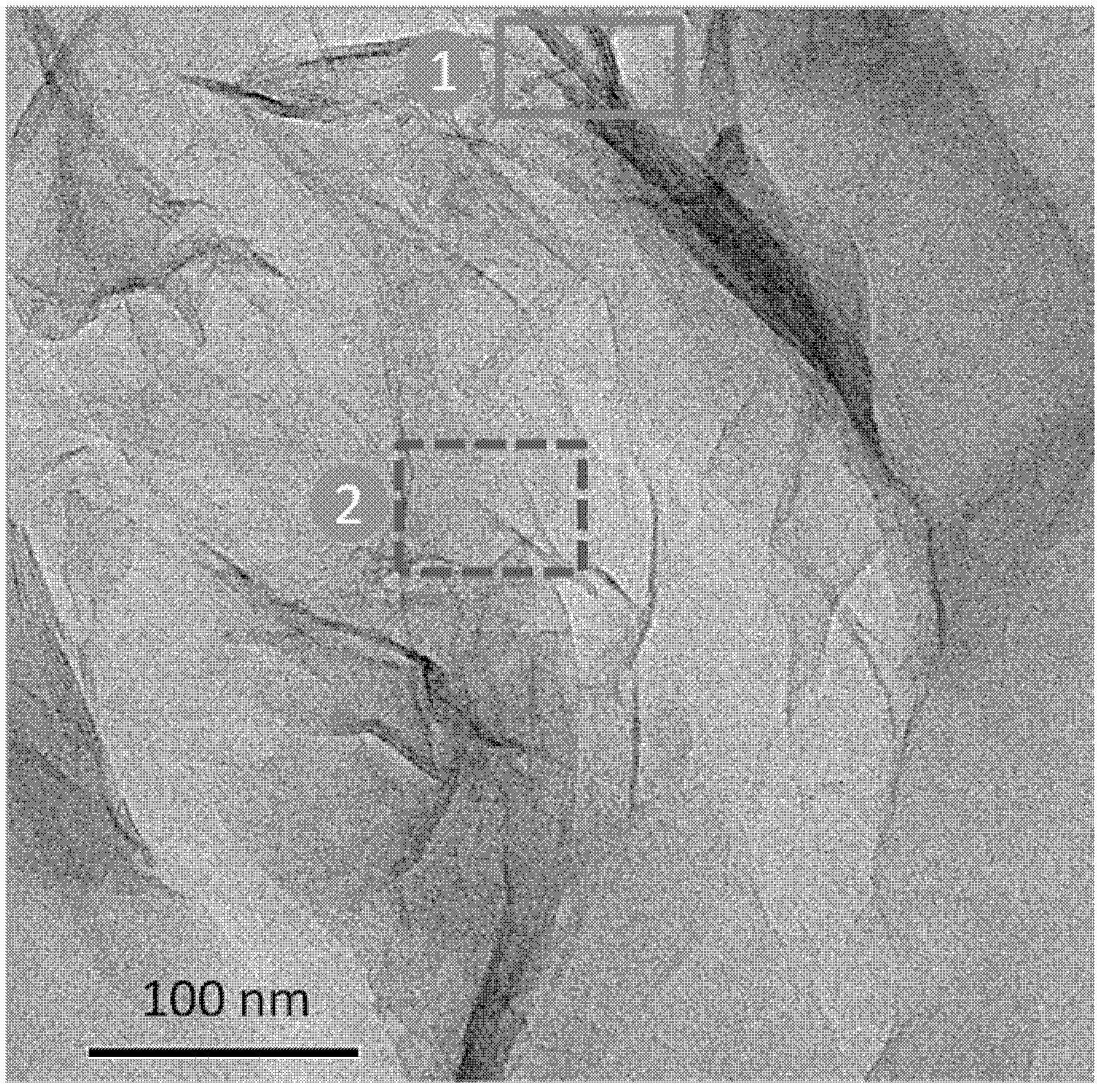

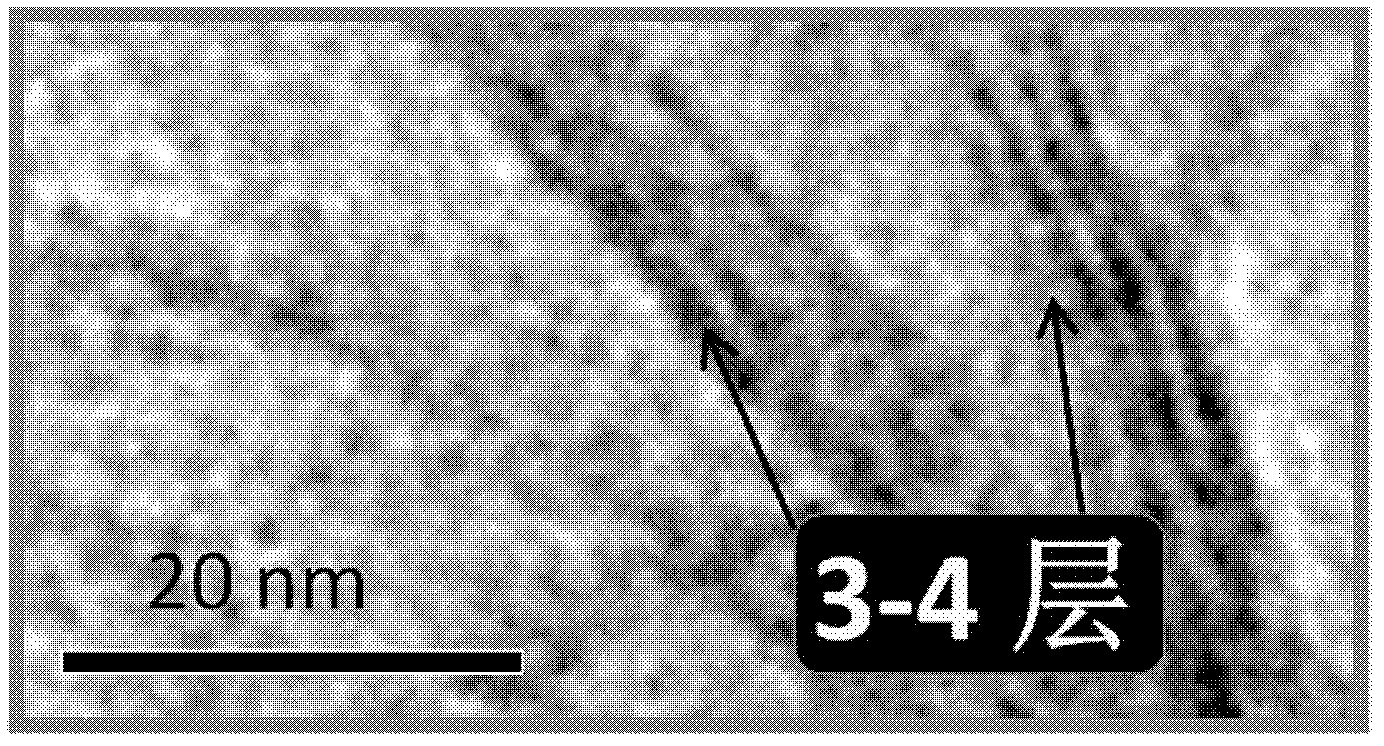

[0038] The present invention first fully mixes the first mass part polymer and graphene in an organic solvent. During the mixing process, since graphene can maintain a delamination state in a solvent environment, in the obtained polymer / graphene master batch, Graphene can maintain monolithic or less lamellar state, uniformly dispersed in the first mass part polymer, and no agglomeration o...

Embodiment 1

[0068] Place the inner liner of the reaction kettle in a refrigerator at 0-4°C for 0.5h and then place it in the shell of a stainless steel reaction kettle, add 20g of cooled graphite, 80g of potassium permanganate and 600mL of Concentrated sulfuric acid, tightly capped and sealed, and placed at room temperature for 0.5h; then the reaction kettle was placed in a 100°C oven and heated for 1.5h to react, the obtained reaction product was poured into 10L deionized water, and the mass concentration was added to 30 % hydrogen peroxide is reduced to a golden yellow solution, then filtered, washed with dilute hydrochloric acid and deionized water to neutrality to obtain graphite oxide;

[0069] Disperse 10 g of the graphene oxide in 1000 g of water, and ultrasonically stir for 1 h to obtain a uniform colloidal solution; add 50 mL of ammonia water with a mass concentration of 25-28% to the colloidal solution, ultrasonically stir for 1 h, and continue to add 20 g of ammonia water with a...

Embodiment 2~8

[0072] After washing the graphene prepared in 10g of Example 1 with tetrahydrofuran, disperse it in 400mL tetrahydrofuran, obtain a graphene dispersion after ultrasonic and stirring for 2h; stir and dissolve 40g polylactic acid in 400mL tetrahydrofuran to obtain a polylactic acid solution; The polylactic acid solution was added to the graphene dispersion, and after ultrasonic and stirring for 1 hour, the obtained black mixture was dried at 50°C to remove tetrahydrofuran, pulverized into powder with a pulverizer, and then vacuum-dried at 80°C for 6 hours to obtain polylactic acid / Graphene masterbatch.

[0073] The polylactic acid / graphene masterbatch is mixed with polylactic acid, blended in an internal mixer at 170°C and a speed of 60rpm for 8min, and then press-molded by a flat vulcanizer at 180°C to obtain graphene The content is 0.02%, 0.04%, 0.08%, 0.2%, 0.5%, 1%, 2% polylactic acid / graphene nano composite material.

[0074] The polylactic acid / graphene nanocomposite mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com