Functionalized homogeneous particle porous silicon dioxide microspheres and preparation method and application thereof

A technology of porous silica and silica, applied in silica, silica, chemical instruments and methods, etc., can solve the problems of uncontrollable mesopore pore size, too small particle size, uneven particle size of microspheres, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

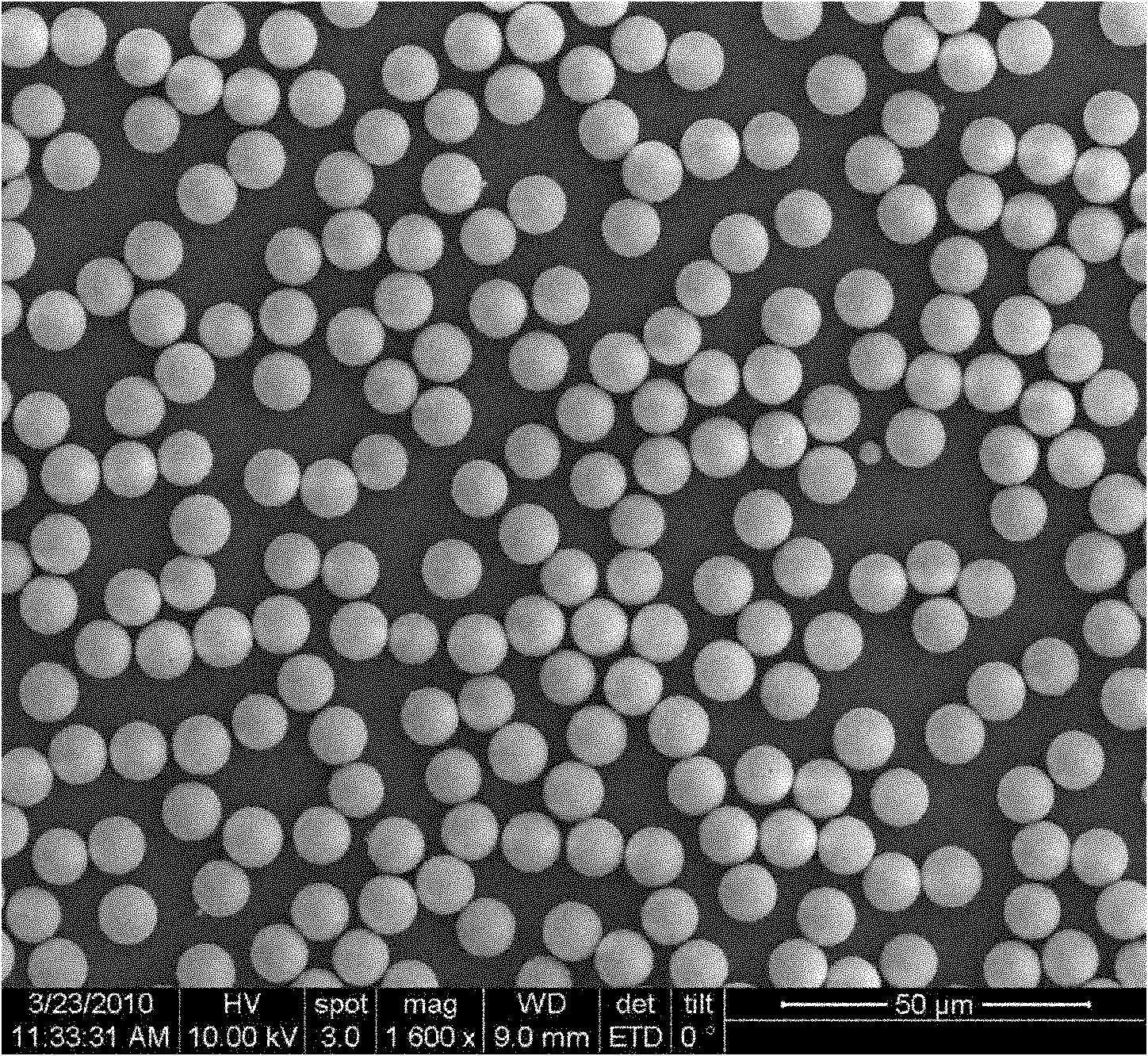

[0062] Example 1 Synthesis of homogeneous porous polystyrene / divinylbenzene polymer microspheres

[0063] Take 30 g of styrene, 60 g of divinylbenzene (80%) and 100 g of cyclohexanol into a 2000 mL three-necked round bottom flask, add 1.5 g of azobisisobutyronitrile as an initiator, and mechanically stir to completely dissolve it. Add 800 g of 0.04% sodium octadecyl sulfonate aqueous solution to the above solution, add 25 g of 2.5 μm polystyrene seeds after ultrasonic emulsification, swell at room temperature for 24 hours and then heat to 80°C for reaction. After cooling, the homogeneous porous cross-linked polystyrene microspheres were separated, the particle size was 5 μm, and the coefficient of variation CV=3.5%.

Embodiment 2

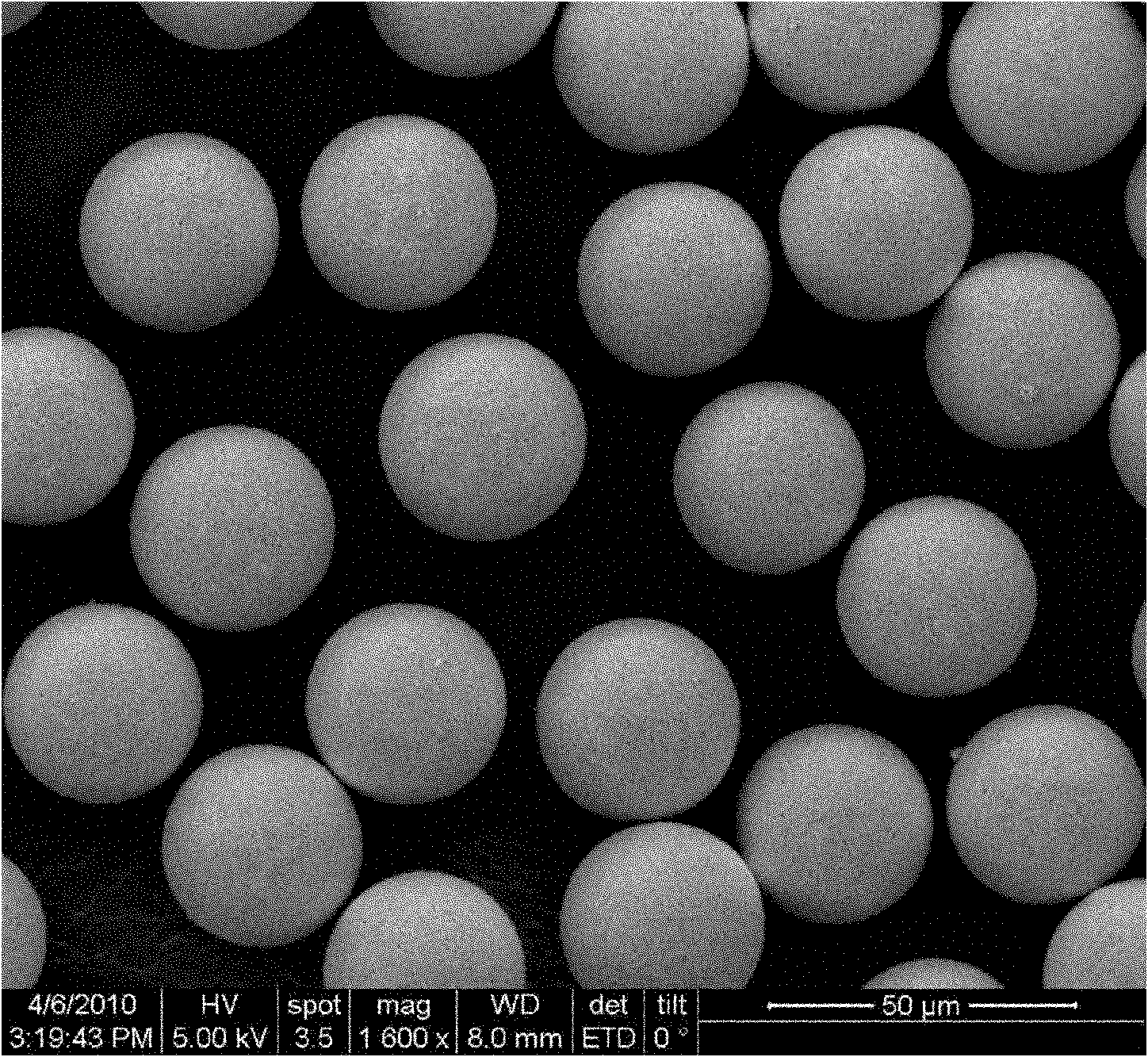

[0064] Example 2 Synthesis of homogeneous porous polystyrene / divinylbenzene polymer microspheres

[0065] Take 30 g of styrene, 60 g of divinylbenzene (80%) and 100 g of cyclohexanol into a 2000 mL three-necked round bottom flask, add 1.5 g of azobisisobutyronitrile as an initiator, and mechanically stir to completely dissolve it. Add 800g of 0.04% sodium octadecyl sulfonate aqueous solution to the above solution, add 25g of 5μm polystyrene seeds after ultrasonic emulsification, swell at room temperature for 24 hours and then heat to 80°C for reaction. After cooling, the homogeneous porous cross-linked polystyrene microspheres were separated, the particle size was 10μm, and the coefficient of variation CV=3.5%.

Embodiment 3

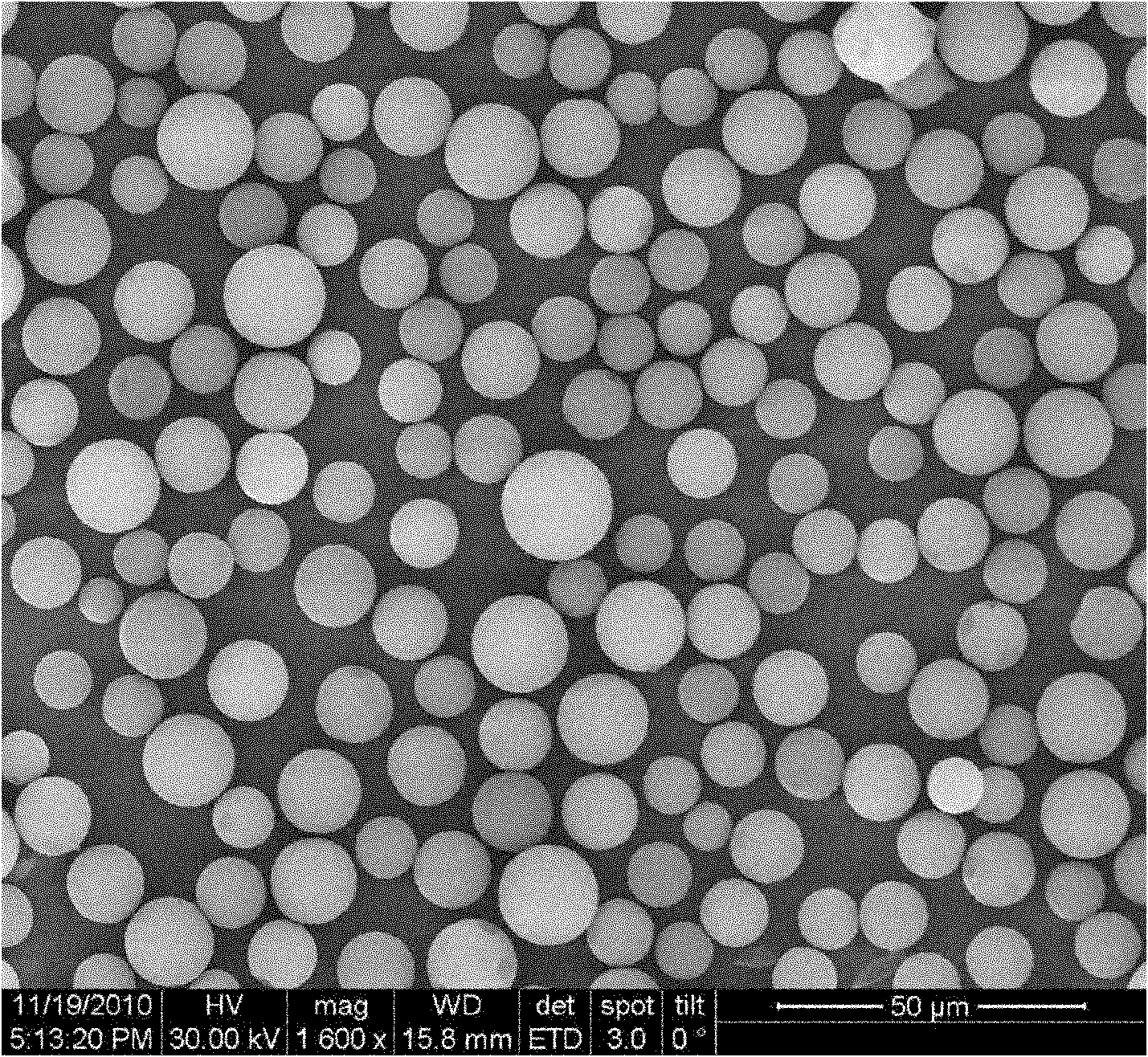

[0066] Example 3 Synthesis of homogeneous porous polystyrene / divinylbenzene polymer microspheres

[0067] In a 5 liter reactor, use pre-prepared 60g monodisperse swellable polystyrene particles as seeds, with a particle size of 13.5μm, CV=3.8, and add 1300g of deionized water containing 1g of hydroxypropylcellulose; Stir and heat to 85°C at a speed of rpm.

[0068] After mixing 800g of styrene and 10g of dibenzoyl peroxide, add 1500g of water containing 0.5g of KI, 0.5g of hydroxypropylcellulose and 4.0g of Triton X-405. After mixing, emulsify and increase the rate at 85℃. Add to the aqueous solution, for example, the initial speed is 1ml / min, the final speed is 10ml / min, and the dripping is for a total of 6 hours to carry out the first-stage reaction, and the reaction degree is controlled to be about 80%.

[0069] Add 800g of styrene and 10g of dibenzoyl peroxide into 1500g of water containing 0.5g of hydroxypropylcellulose and 4.0g of TritonX-405, mix and emulsify, adjust the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com