High-entropy ceramic modified coating with controllable components and controllable microstructure, and preparation method thereof

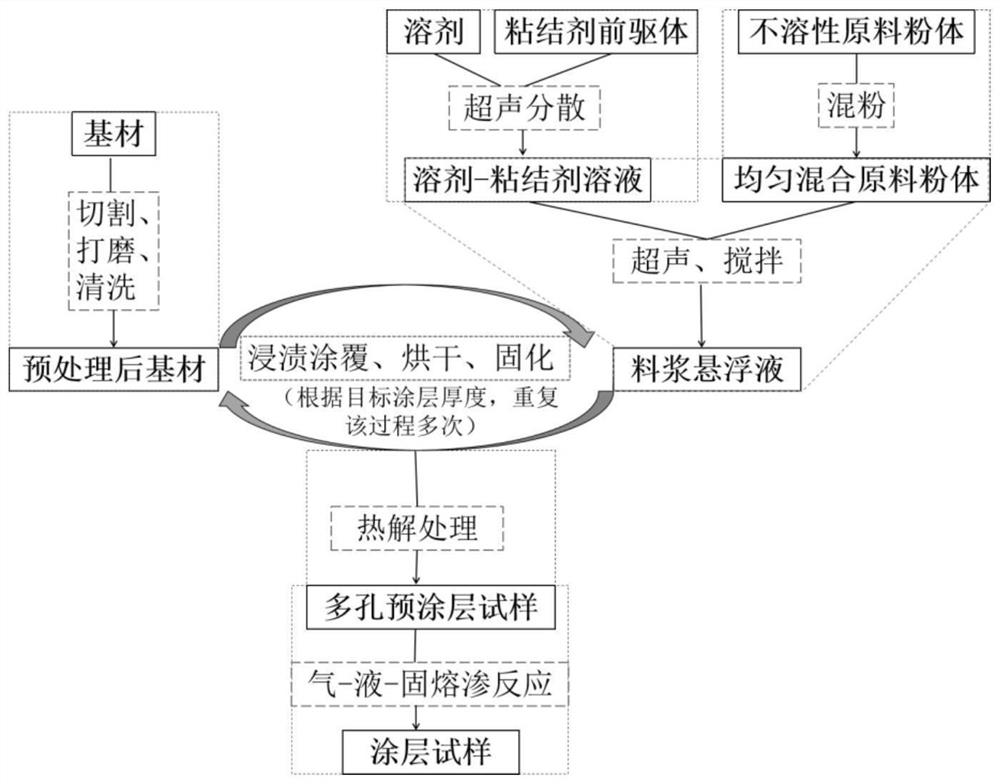

A technology for modifying coatings and microstructures, which is used in infiltration-assisted in-situ reaction preparation of components, microstructure controllable high-entropy ceramic modified coatings and preparation, and composition and microstructure controllable high-entropy ceramic modified coatings It can solve the problems of insufficient oxidation resistance, ablation resistance and erosion resistance, low content of ultra-high temperature ceramic phase, insufficient development system, etc., to achieve improved hardness and high temperature oxidation corrosion resistance, strong cohesive bonding force, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

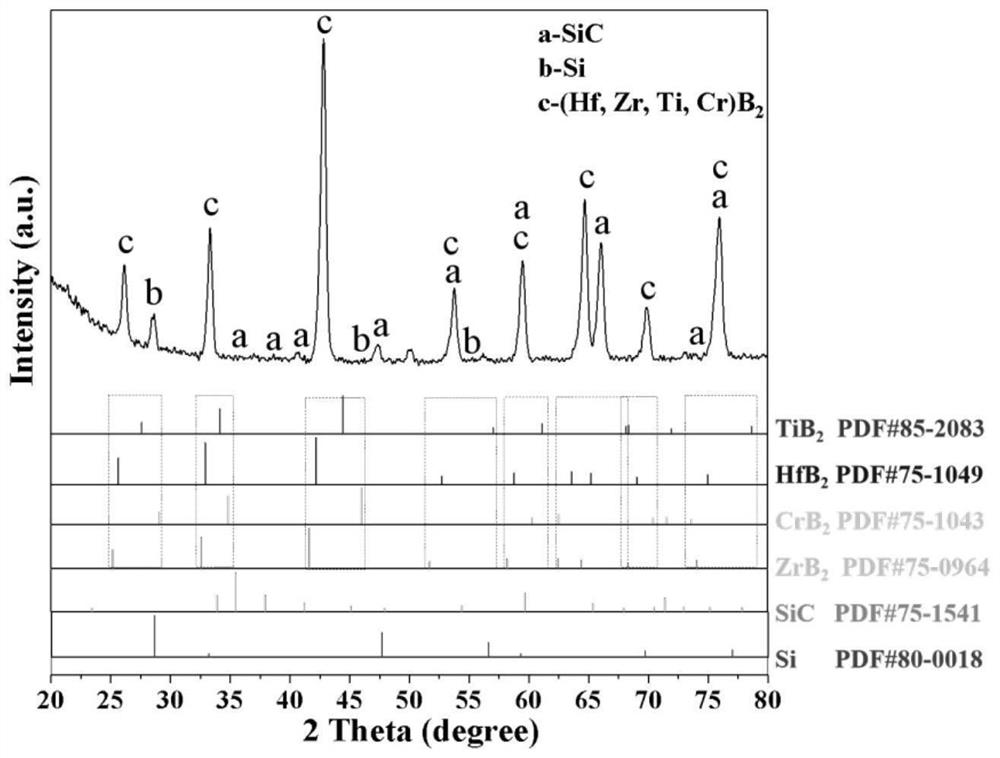

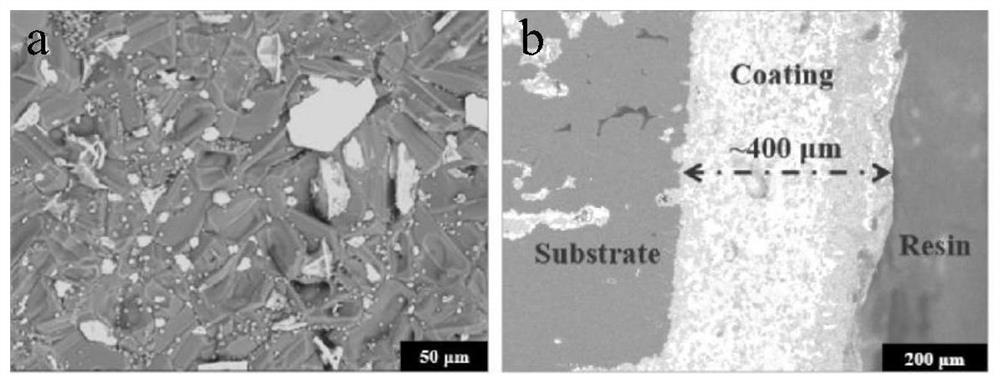

[0075] Vapor-phase siliconizing (Si) assisted multi-principal element (Hf, Zr, Ti, Cr) B 2 Preparation of SiC-Si coating modified by solid solution of ultra-high temperature and high entropy ceramics:

[0076] Step 1: Select 2.5D carbon / carbon (C / C) composite material as the substrate and pre-treat it:

[0077] Cut the selected substrate into the shape required for testing and characterization, sand it with sandpaper, remove the corners, ultrasonically clean it in industrial alcohol for 60 minutes, and then dry it in an oven at 393K for 3 hours;

[0078] Step 2: Preparation of PR-TM x o y -B 4 C-SiC-C slurry suspension (referred to as A):

[0079] Anhydrous ethanol was selected as the solvent, and thermosetting phenolic resin (PR) with a carbon production rate of 53wt.% was used as the binder precursor and as the carbon source. First put PR and absolute ethanol in a beaker with a mass ratio of 5:100 for ultrasonic dispersion for 30 minutes to obtain a uniform PR-absolute ...

Embodiment 2

[0093] Zirconium silicide (ZrSi 2 ) Auxiliary (Hf, Zr, Ti, Cr, Ta) B 2 -ZrC-SiC / ZrC-SiC coating preparation:

[0094] Step 1: Choose a density of 1800kg / m 3 The high-strength graphite is used as the base material, and it is pretreated:

[0095] Cut the selected substrate into the shape required for testing and characterization, sand it with sandpaper, remove the corners, ultrasonically clean it in industrial alcohol for 50 minutes, and then dry it in an oven at 383K for 5 hours;

[0096] Step 2: Prepare PCS-C slurry suspension (denoted as B) and PR-TM x o y -B 4 C-SiC-C slurry suspension (referred to as C):

[0097] Xylene is selected as a solvent, and polycarbosilane (PCS), a SiC ceramic precursor with a ceramization yield of 63wt.%, is used as a binder and also as a source of SiC ceramics. Polycarbosilane (PCS), graphite (C) powder, and xylene were placed in a beaker at a mass ratio of 3:1:20, heated to 333K, and ultrasonically dispersed for 60 minutes to obtain a uni...

Embodiment 3

[0112] Embedding solidification titanium (Ti) powder assisted ((Hf, Zr, Ti, Cr, Ta) B 2 -SiC-TiC-Ti) 4 Multi-layer gradient coating preparation:

[0113] Step 1: Select 2.5D carbon / carbon (C / C) composite material as the substrate and pre-treat it:

[0114] Cut the selected substrate into the shape required for testing and characterization, sand it with sandpaper, remove the corners, ultrasonically clean it in industrial alcohol for 30 minutes, and then dry it in an oven at 383K for 3 hours;

[0115] Step 2: Preparation of PR-TM with four different ultra-high temperature ceramic precursor powder contents x o y -B 4 C-SiC-C slurry suspension (denoted as D, E, F and G in sequence):

[0116]Acetone was selected as the solvent, and thermosetting phenolic resin (PR) with a carbon yield of 53wt.% was used as the binder precursor and as the carbon source. First put PR and acetone in a beaker with a mass ratio of 3:50 for ultrasonic dispersion for 30 minutes to obtain a uniform P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com