Surface treatment method for improving corrosion resistance of carbon steel

A technology for surface treatment and corrosion resistance, which is applied in the field of surface treatment for the preparation of corrosion-inhibiting anion intercalated iron-based hydrotalcite films on the surface of carbon steel, which can solve the difficulties of hydrotalcite films, limited treatment methods, and unfavorable large-scale Application and other issues, to achieve large-scale industrial application, low cost, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

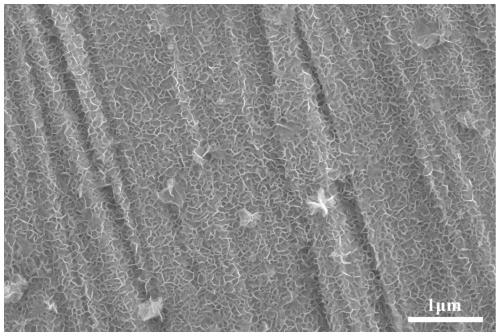

[0024] A corrosion-inhibiting anion-intercalated iron-based hydrotalcite film was prepared on the surface of carbon steel, and the corrosion resistance of the film was investigated.

[0025] (1) Pretreatment of carbon steel surface:

[0026] The surface of Q235 carbon steel sample of 15mm × 15 mm × 3 mm was polished with 150#, 240#, 400#, 800#, 1000# silicon carbide sandpaper, rinsed with deionized water, dried with cold wind, and dried in anhydrous Ultrasonic cleaning in ethanol for 5 minutes, take out, rinse with deionized water, dry with cold air, and set aside.

[0027] (2) The iron-based hydrotalcite film layer was directly prepared on the surface of the carbon steel sample:

[0028] At room temperature, weigh 0.002 mol of NiSO 4 •6H 2 O, add deionized water to prepare 1000 μmol / L NiSO 4 Aqueous solution, take 400mL for later use;

[0029] Hang the Q235 carbon steel sample treated in step (1) vertically in the above 1000 μmol / L NiSO 4 After soaking in the solution f...

Embodiment 2

[0035] A corrosion-inhibiting anion-intercalated iron-based hydrotalcite film was prepared on the surface of carbon steel, and the corrosion resistance of the film was investigated.

[0036] (1) Pretreatment of carbon steel surface:

[0037] The surface of Q235 carbon steel sample of 15mm × 15 mm × 3 mm was polished with 150#, 240#, 400#, 800#, 1000# silicon carbide sandpaper, rinsed with deionized water, dried with cold wind, and dried in anhydrous Ultrasonic cleaning in ethanol for 5 minutes, take out, rinse with deionized water, dry with cold air, and set aside.

[0038] (2) The iron-based hydrotalcite film layer was directly prepared on the surface of the carbon steel sample:

[0039] At room temperature, weigh 0.004 mol of NiSO 4 •6H 2 O, add deionized water to prepare 2000 μmol / L NiSO 4 Aqueous solution, take 300mL for later use;

[0040] Hang the Q235 carbon steel sample treated in step (1) vertically in the above 2000 μmol / L NiSO 4 After soaking in the solution f...

Embodiment 3

[0045] A corrosion-inhibiting anion-intercalated iron-based hydrotalcite film was prepared on the surface of carbon steel, and the corrosion resistance of the film was investigated.

[0046] (1) Pretreatment of carbon steel surface:

[0047] The surface of Q235 carbon steel sample of 15mm × 15 mm × 3 mm was polished with 150#, 240#, 400#, 800#, 1000# silicon carbide sandpaper, rinsed with deionized water, dried with cold wind, and dried in anhydrous Ultrasonic cleaning in ethanol for 5 minutes, take out, rinse with deionized water, dry with cold air, and set aside.

[0048] (2) The iron-based hydrotalcite film layer was directly prepared on the surface of the carbon steel sample:

[0049] At room temperature, weigh 0.002 mol of ZnSO 4 •7H 2 O, add deionized water to prepare 1000 μmol / L ZnSO 4 Aqueous solution, take 300mL for later use;

[0050] Hang the Q235 carbon steel sample treated in step (1) vertically in the above 1000 μmol / L ZnSO 4 After soaking in the solution f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com