Preparation method of doped CO2 (carbon dioxide) calcium base adsorbent

A calcium-based adsorbent, CO2 technology, which is applied in the field of preparation of doped CO2 calcium-based adsorbent, can solve the problems of poor cycle adsorption stability, low conversion rate and high cost, and achieves improvement of calcium-based cycle adsorption performance, reduced cost, and low cost. Inexpensive, improve the effect of easy sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Without doping, directly use the calcium source extracted from calcium carbide slag as the CaO precursor to prepare CO 2 Calcium-based adsorbent, the specific steps are as follows:

[0032] Weigh 5g of calcium carbide slag to clean and remove impurities attached to the surface, dry it in an oven for 4 hours, and then crush it with a high-grade crusher; place the obtained material in a muffle furnace at a temperature of 900°C for 4 hours and calcinate to obtain a calcium-based adsorbent prepared from calcium carbide slag.

[0033] The composition table of the calcined carbide slag measured by XRF (output in the form of oxides) is shown in Table 1 below; the results show that the content of CaO in the calcined carbide slag is as high as 85.12wt%, and it also contains The component MgO.

[0034] Table 1 Composition list of calcium carbide slag after calcination

[0035]

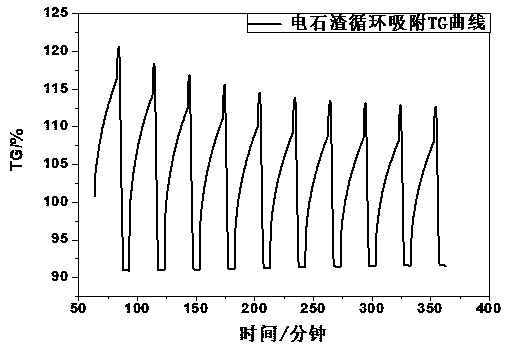

[0036] The resulting product was placed in a thermogravimetric analyzer for cycling CO 2 Adsorpt...

Embodiment 2

[0041] Without doping, the calcium source extracted from egg shells was directly used as the CaO precursor to prepare CO 2 Calcium-based adsorbent, the specific steps are as follows:

[0042] Weigh 5g of egg shells, wash and remove impurities attached to the surface, bake in an oven for 3 hours, then crush them with a high-grade crusher, and place the resulting material in a muffle furnace at a temperature of 900°C for 5 hours to obtain a calcium-based adsorbent prepared from calcium carbide slag .

[0043] The resulting product was placed in a thermogravimetric analyzer for cycling CO 2 Adsorption investigation.

[0044] CO 2 The cycle adsorption performance test method is the same as in Example 1, and the results show that the first adsorption CaO conversion rate is 55.31%, and after 10 times of CO 2 The conversion of CaO after adsorption / desorption cycles was 32.76%.

Embodiment 3

[0046] A doped CO 2 The preparation method of calcium-based adsorbent specifically comprises the following steps:

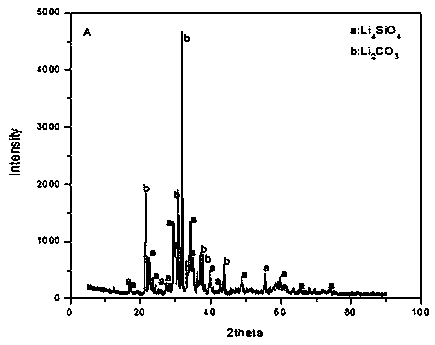

[0047] (1) At room temperature, weigh Li according to the molar ratio of lithium and silicon n(Li):n(Si) is 4.5:1 2 CO 3 and SiO 2 , then put it into a mortar, add an appropriate amount of water to make it fully mixed, and dry it in an oven at 50°C after mixing;

[0048] (2) Put the dried mixture obtained in step (1) into a crucible, and bake it in a muffle furnace at 600°C for 5 hours;

[0049] (3) Put the sample obtained in step (2) into a mortar and grind for 5 minutes to obtain Li 4 SiO 4 powder;

[0050] (4) Take a certain amount of waste calcium carbide slag, wash and remove impurities attached to the surface, bake in an oven for 3 hours, then crush it with a high-grade crusher, and then put it in a muffle furnace for calcination at 800°C for 3 hours to extract calcium base;

[0051] (5) the dopant Li obtained in step (3) 4 SiO 4 Powder and step (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com