Nickel-molybdenum carbide nanoparticle/carbon fiber composite nano material, preparation method and application of nickel-molybdenum carbide nanoparticle/carbon fiber composite nano material

A technology of composite nanomaterials and nanoparticles, which is applied in the field of controllable preparation of non-precious metal-based carbon fiber composite nanomaterials, can solve the problems of expensive metal catalysts, poor stability and inability to be used on a large scale, and achieve excellent catalytic activity, high-efficiency preparation, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

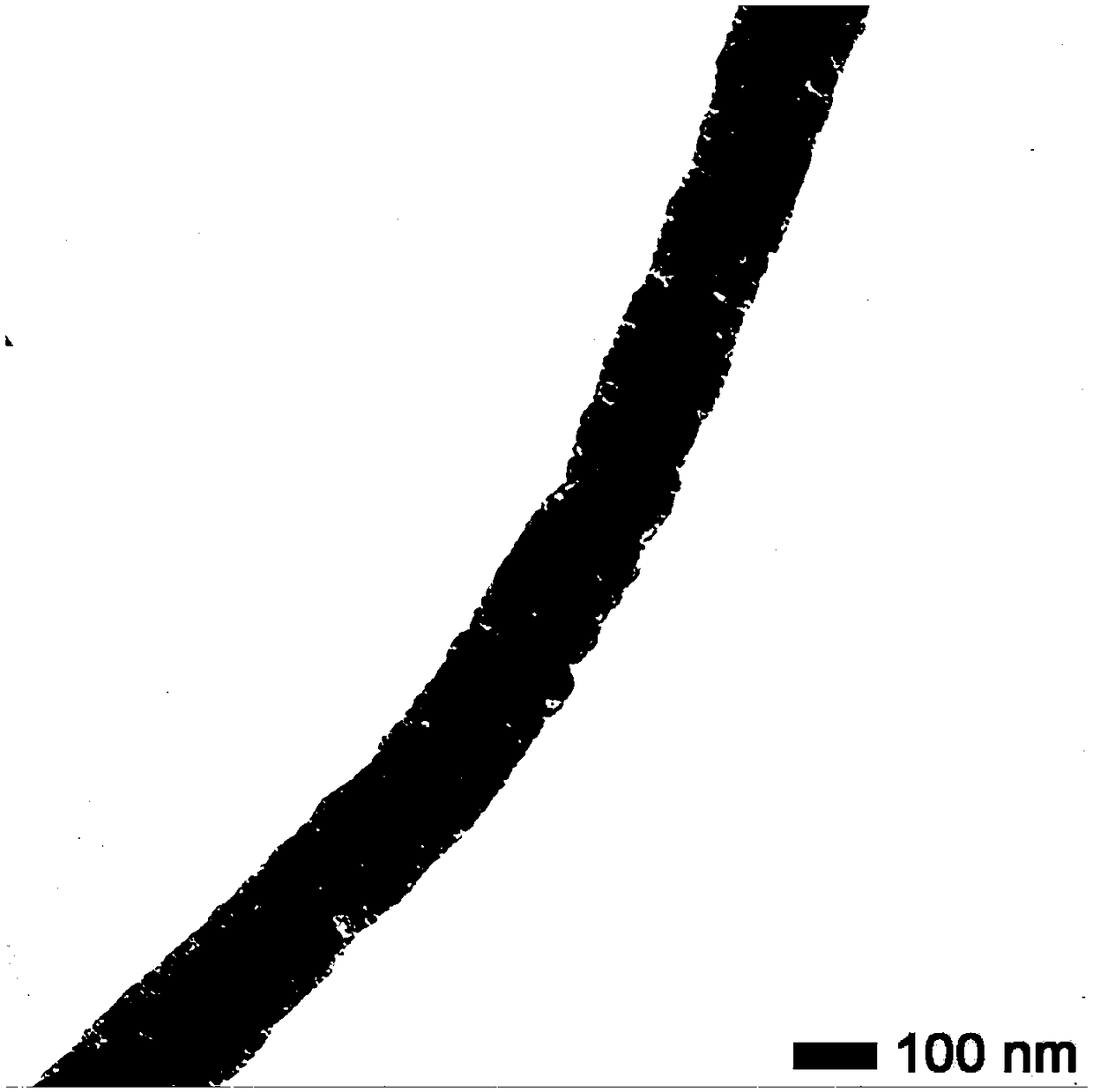

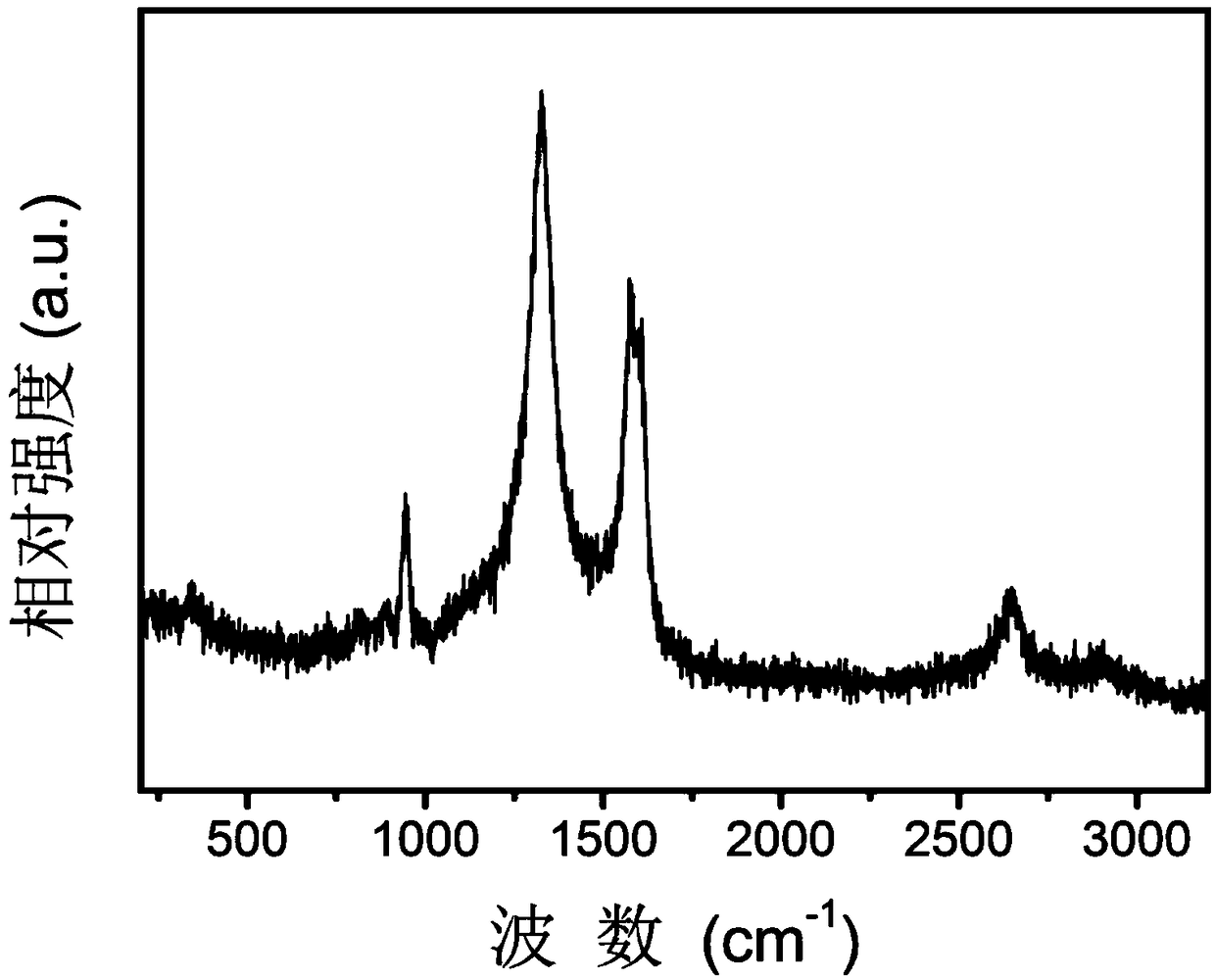

Embodiment 1

[0026] Dissolve 0.2g PAN in 2.3g DMF, stir magnetically at 90°C, after all PAN is dissolved, add 0.067g Ni(Ac) 2 4H 2 O and 0.133g MoO 2 (acac) 2 Dissolve in the above solution and stir overnight to obtain a homogeneous thick spinning solution precursor. Inject the spinning liquid precursor into the glass spinning tube of the electrospinning device, the spinning distance is 20cm, the spinning voltage is 18kV, and finally PAN / Ni(Ac) 2 4H 2 O / MoO 2 (acac) 2 Composite nanofiber membrane.

Embodiment 2

[0028] Dissolve 0.2g PAN in 2.3g DMF, stir magnetically at 90°C, after the PAN is completely dissolved, add 0.1g Ni(Ac) 2 4H 2 O and 0.1 g MoO 2 (acac) 2 Dissolve in the above solution and stir overnight to obtain a homogeneous thick spinning solution precursor. Inject the spinning liquid precursor into the glass spinning tube of the electrospinning device, the spinning distance is 20cm, the spinning voltage is 18kV, and finally PAN / Ni(Ac) 2 4H 2 O / MoO 2 (acac) 2 Composite nanofiber membrane.

Embodiment 3

[0030] Dissolve 0.2g PAN in 2.3g DMF, stir magnetically at 90°C, after all PAN is dissolved, add 0.133g Ni(Ac) 2 4H 2 O and 0.067g MoO 2 (acac) 2 Dissolve in the above solution and stir overnight to obtain a homogeneous thick spinning solution precursor. Inject the spinning liquid precursor into the glass spinning tube of the electrospinning device, the spinning distance is 20cm, the spinning voltage is 18kV, and finally PAN / Ni(Ac) 2 4H 2 O / MoO 2 (acac) 2 Composite nanofiber membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com