Treatment method for flue gas denitrification by catalysis of carbon-based metal organic framework type oxide

A metal-organic framework and organic framework technology, applied in the field of environmental protection science, can solve problems such as reducing energy consumption and disadvantages, and achieve the effects of reducing energy consumption and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

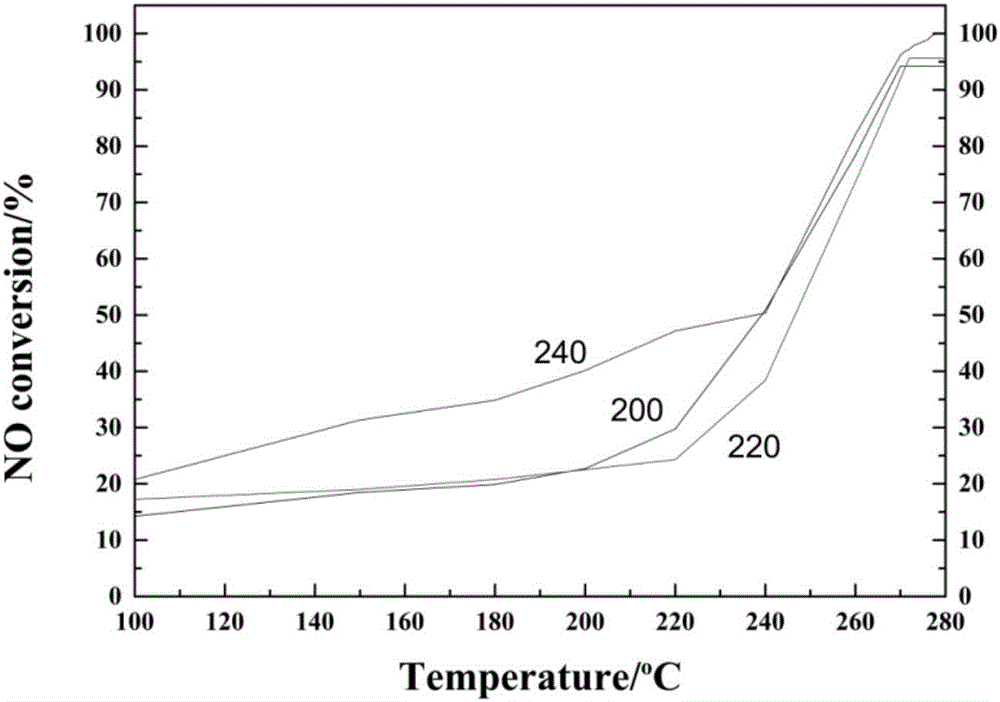

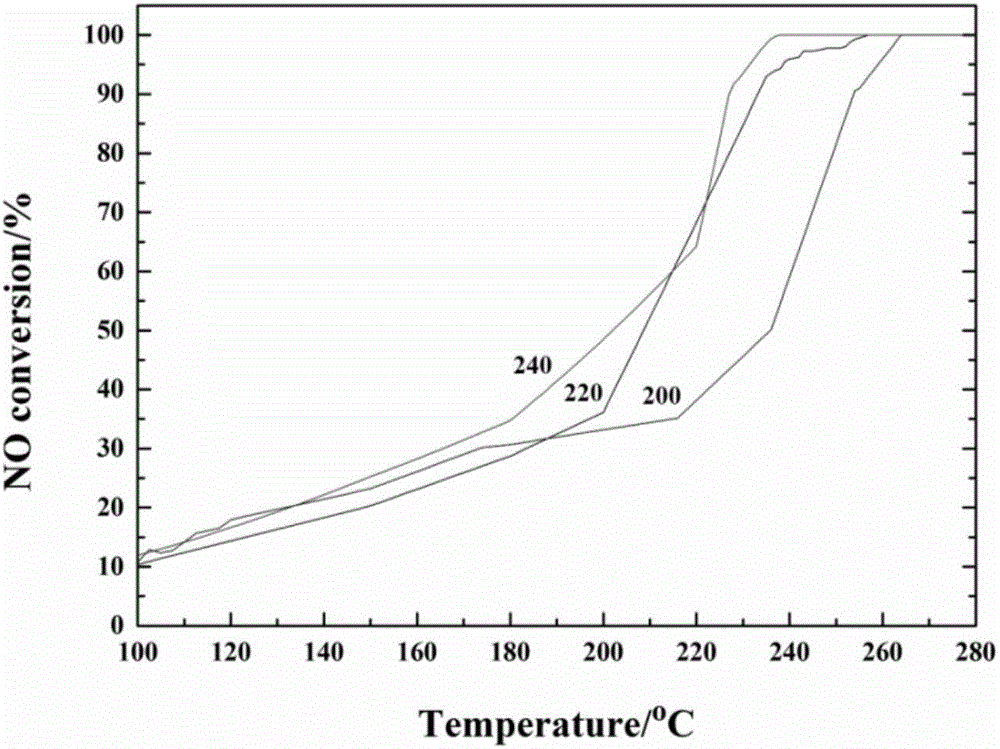

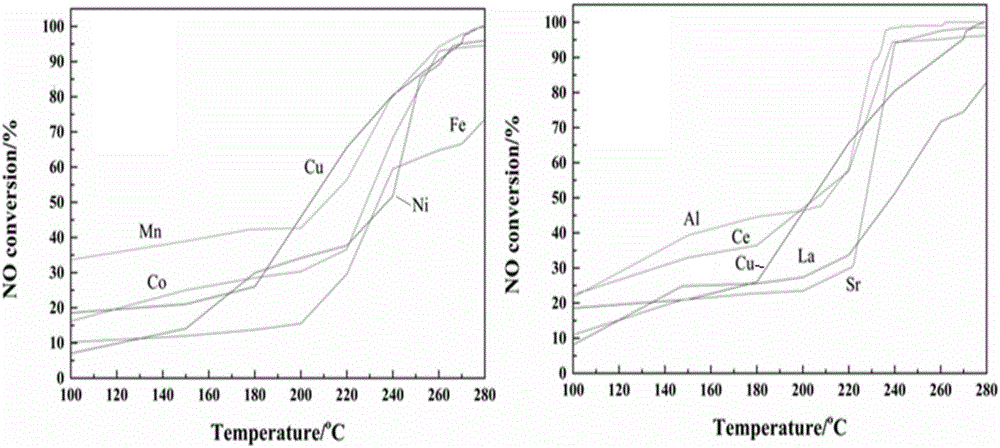

[0029] Example 1: Cu z O / C,0

[0030] Load 10g of catalyst Cu into the reactor of the tubular resistance furnace z O / C, first bubbling nitrogen for 5 minutes, then start to heat up, and at the same time pass in a mixed gas of carbon monoxide and nitric oxide (the volume percentage of carbon monoxide is 30%, the volume percentage of nitric oxide is 30%, the rest is nitrogen), the space velocity is 12000mL / (g·h), after the tail gas is detected by the flue gas analyzer, it is passed into the lime water and then recovered. When the denitration rate is close to 100%, it is kept at a constant temperature. When the temperature is 174℃, the denitration efficiency is 100%, N 2 The recovery rate was 95.3%, indicating a good low-temperature catalytic denitrification effect.

Embodiment 2

[0031] Example 2: Sr y O / Cu z O / C, 0

[0032] Load 10g Sr into the reactor of the tubular resistance furnace y O / Cu z For O / C catalyst, first pass nitrogen gas for 5 minutes, then start to heat up, and pass a mixed gas of carbon monoxide and nitrogen dioxide (60% by volume of carbon monoxide, 30% by volume of nitrogen dioxide, and the rest is nitrogen), the space velocity is 12000mL / (g·h), the tail gas is detected by a flue gas analyzer and then passed into lime water for recovery. When the denitrification rate is close to 100%, it is kept at a constant temperature. The denitration efficiency is 100% when the temperature is 172℃, N 2 The recovery rate was 96.1%, indicating a good low-temperature catalytic denitrification effect.

Embodiment 3

[0033] Example 3: Ni x O / Fe y O / Co z O / C, 0

[0034] Load 10g Ni in the reactor of the tubular resistance furnace x O / Fe y O / Co z For O / C catalyst, first pass nitrogen gas for 5 minutes, then start to heat up, and pass a mixed gas of carbon monoxide and nitric oxide (30% by volume of carbon monoxide, 30% by volume of nitric oxide, and the rest is nitrogen), and the space velocity is 10000mL / (g·h), the tail gas is detected by the flue gas analyzer and then passed into lime water for recovery. When the denitrification rate is close to 100%, it is kept at a constant temperature. The denitration efficiency is 99.9% when the temperature is 102℃, N 2 The recovery rate was 95.8%, indicating a good low-temperature catalytic denitrification effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com