Transparent thin film transistor device based on zirconium oxide and lanthanum oxide and preparation method thereof

A transparent film and lanthanum oxide technology, which is applied in semiconductor/solid-state device manufacturing, transistors, semiconductor devices, etc., can solve problems such as inability to mass-produce, high manufacturing cost, and unguaranteed performance of TFT devices, and achieve large-scale industrial Application, process compatibility, effect of reducing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

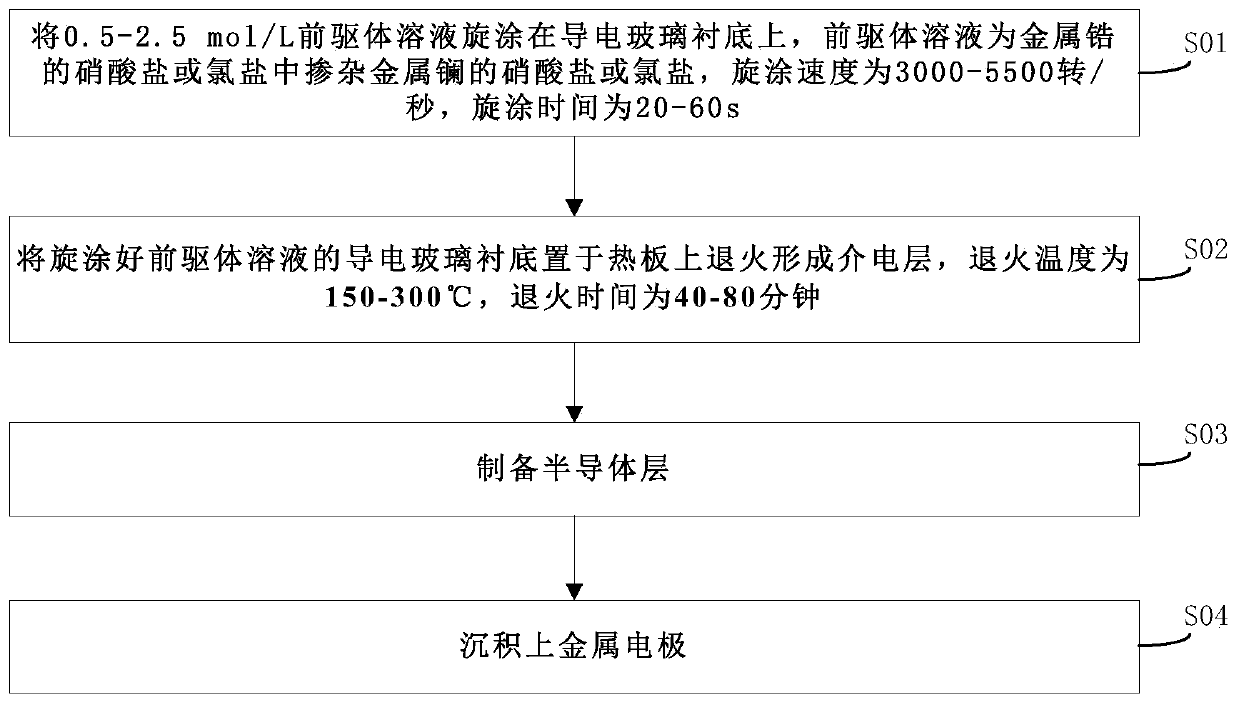

[0034] Such as figure 1 As shown, the present invention discloses a method for preparing a transparent thin film transistor device based on zirconia and lanthanum oxide, comprising the following steps:

[0035] S01: Spin-coat a 0.5-2.5 mol / L precursor solution on a conductive glass substrate. The precursor solution is the nitrate or chloride salt doped with metal lanthanum in the nitrate or chloride salt of metal zirconium, and the nitrate or chloride salt doped with metal lanthanum. The concentration of nitrate or chloride salt accounts for 0-50% of the total concentration, the spin-coating speed is 3000-5500 rpm, and the spin-coating time is 20-60s;

[0036] S02: Place the conductive glass substrate spin-coated with the precursor solution on a hot plate to anneal to form a dielectric layer, the annealing temperature is 150-300°C, and the annealing time is 40-80 minutes;

[0037] S03: Prepare a semiconductor layer; including:

[0038] The semiconductor precursor drug is dis...

Embodiment 1

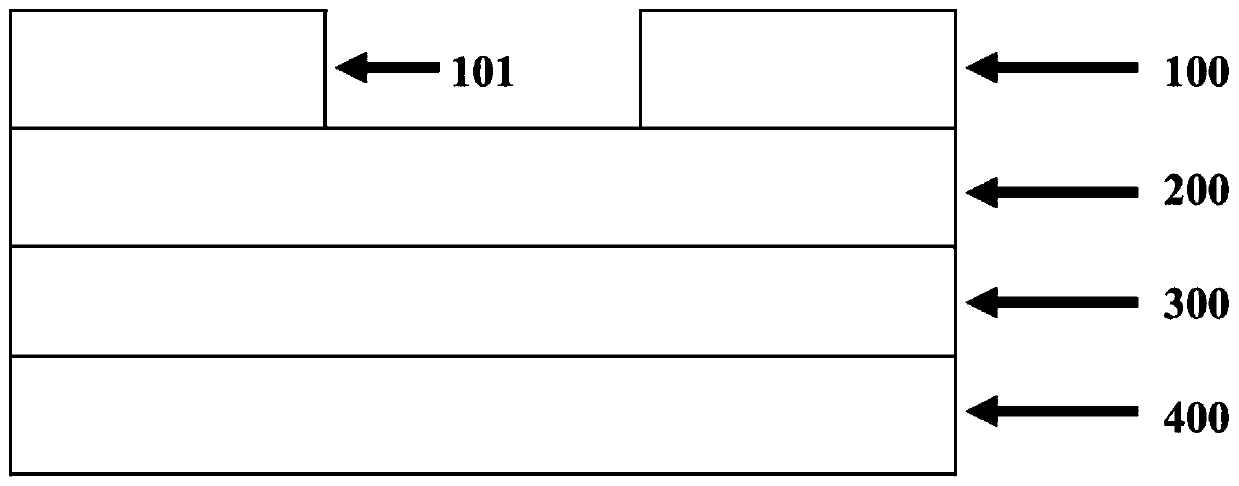

[0048] Such as figure 2 As shown, a transparent TFT device based on zirconia and lanthanum oxide includes a conductive glass substrate 400, a dielectric layer 300, a semiconductor layer 200, an upper metal electrode (100, 101), and an upper metal electrode (100, 101); The electrodes include a source electrode 100 and a drain electrode 101, the conductive material of the conductive glass substrate is indium tin oxide, the material of the semiconductor layer is selected from indium oxide, and the upper metal electrode is indium tin oxide.

[0049] Its preparation method, concrete steps comprise:

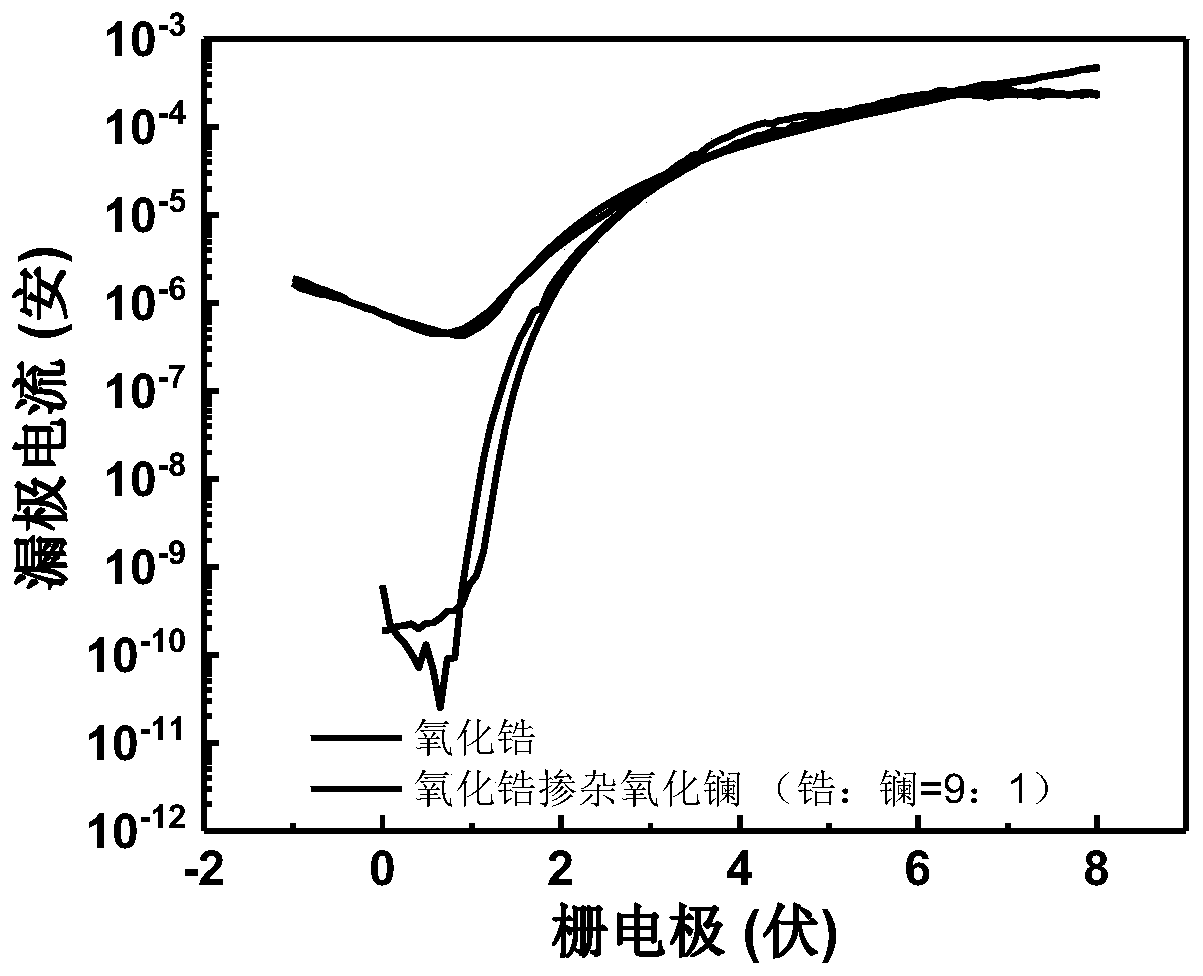

[0050] a) Dissolve the precursor drug in the aqueous solution to obtain a precursor solution with a concentration of 2.5mol / L. The precursor drug is doped with zirconium nitrate and lanthanum nitrate, and the ratio of the two is 9:1;

[0051] b) Sonicate the precursor solution for 15 minutes;

[0052]c) Clean the conductive glass substrate. The conductive material of the conductive ...

Embodiment 2

[0060] Such as Figure 4 As shown, a transparent TFT device based on zirconia and lanthanum oxide includes a conductive glass substrate 800, a dielectric layer 700, a semiconductor layer 600, and an upper metal electrode arranged sequentially from bottom to top; the upper metal electrode includes a source electrode 500 and the drain electrode 501; the conductive material of the conductive glass substrate is indium tin oxide; the material of the semiconductor layer is selected from zinc oxide, and the upper metal electrode is indium tin oxide.

[0061] Its preparation method, concrete steps comprise:

[0062] a) Dissolve the precursor drug in the aqueous solution to obtain a precursor solution with a concentration of 2.5mol / L. The precursor drug is doped with zirconium chloride and lanthanum chloride, and the ratio of the two is 9:1;

[0063] b) Sonicate the precursor solution for 15 minutes;

[0064] c) To clean the conductive glass substrate, immerse the conductive glass su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com