Distributed type intermittent thermal production control system

A control system, distributed technology, applied in heating system, hot water central heating system, space heating and ventilation, etc., can solve the problem of high return water temperature, unfavorable heat user's pressure head, difficult to balance and meet Heat users have different heat needs and other issues, achieving significant environmental benefits, reducing energy consumption in transmission and distribution, and eliminating or reducing the pressure head of excess resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

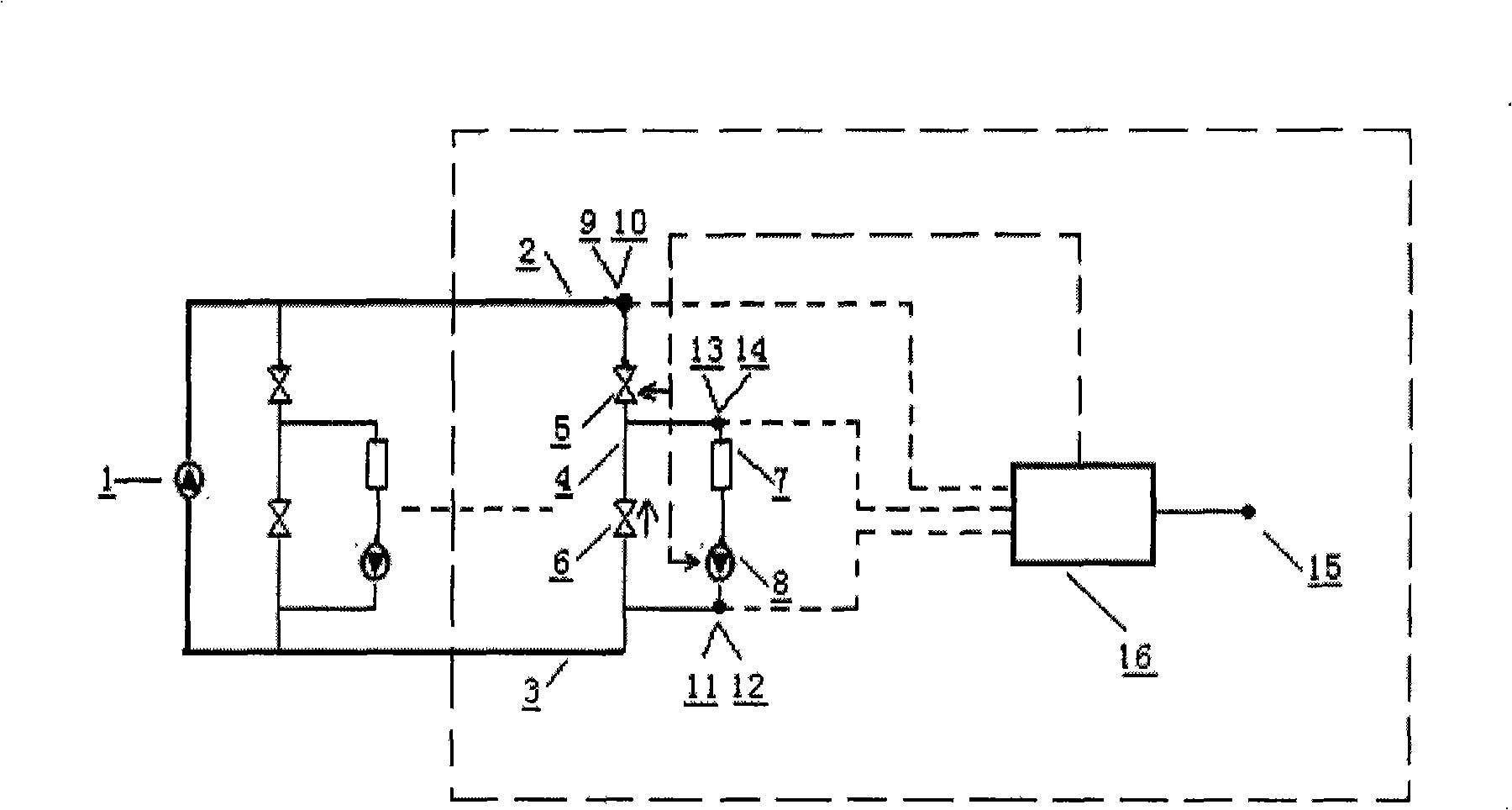

[0016] This system includes: the main network water supply pipe 2 and the return water pipe 3 connected to the heat source, the bypass pipe 4 connected to the branch water supply and return pipes of the building, and the electric switch valve 5 on the branch water supply pipe, that is, the main pipeline of the building. Manual valve on the bypass pipe 6, heat user building 7, variable frequency heat user pump 8, supply water temperature and pressure sensors 9, 10, return water temperature and pressure sensors 11, 12, mixed water temperature and pressure sensors 13, 14 , ambient temperature sensor 15 and intelligent controller 16.

[0017] The system works as follows:

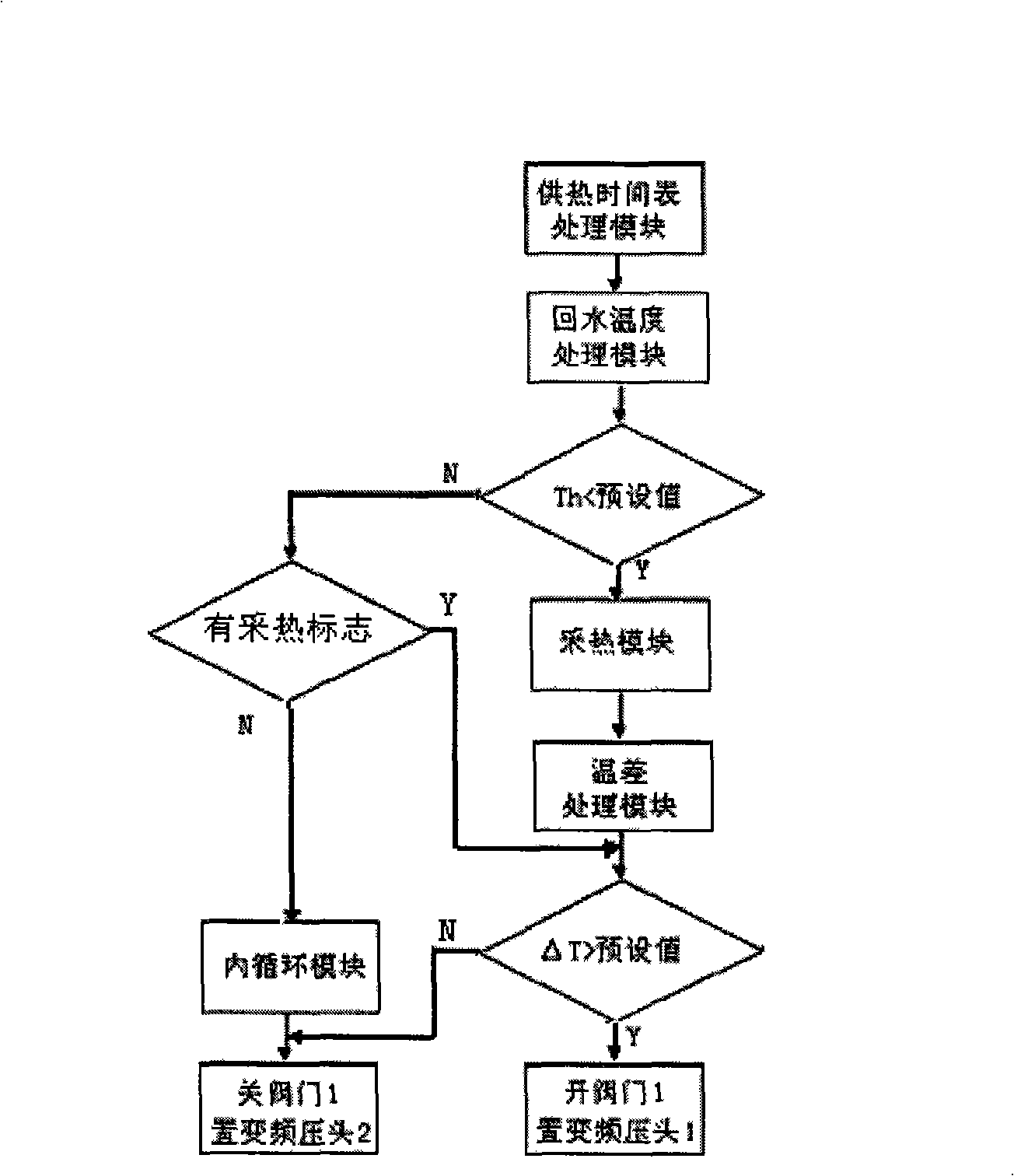

[0018] During the rough debugging of the system, according to the actual situation of the heat users (ground heat, cooling fins, etc.), the water mixing ratio required by the manual valve 6 does not need to be changed after the manual valve 6 is adjusted. During normal heat supply, the intelligent controller 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com