Air source heat pump system capable of intermittently supplying heat under defrosting operating condition

An air source heat pump and working condition technology, which is applied in heat pumps, compressors with reversible cycles, lighting and heating equipment, etc. The effect of impacting each other and improving the defrosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

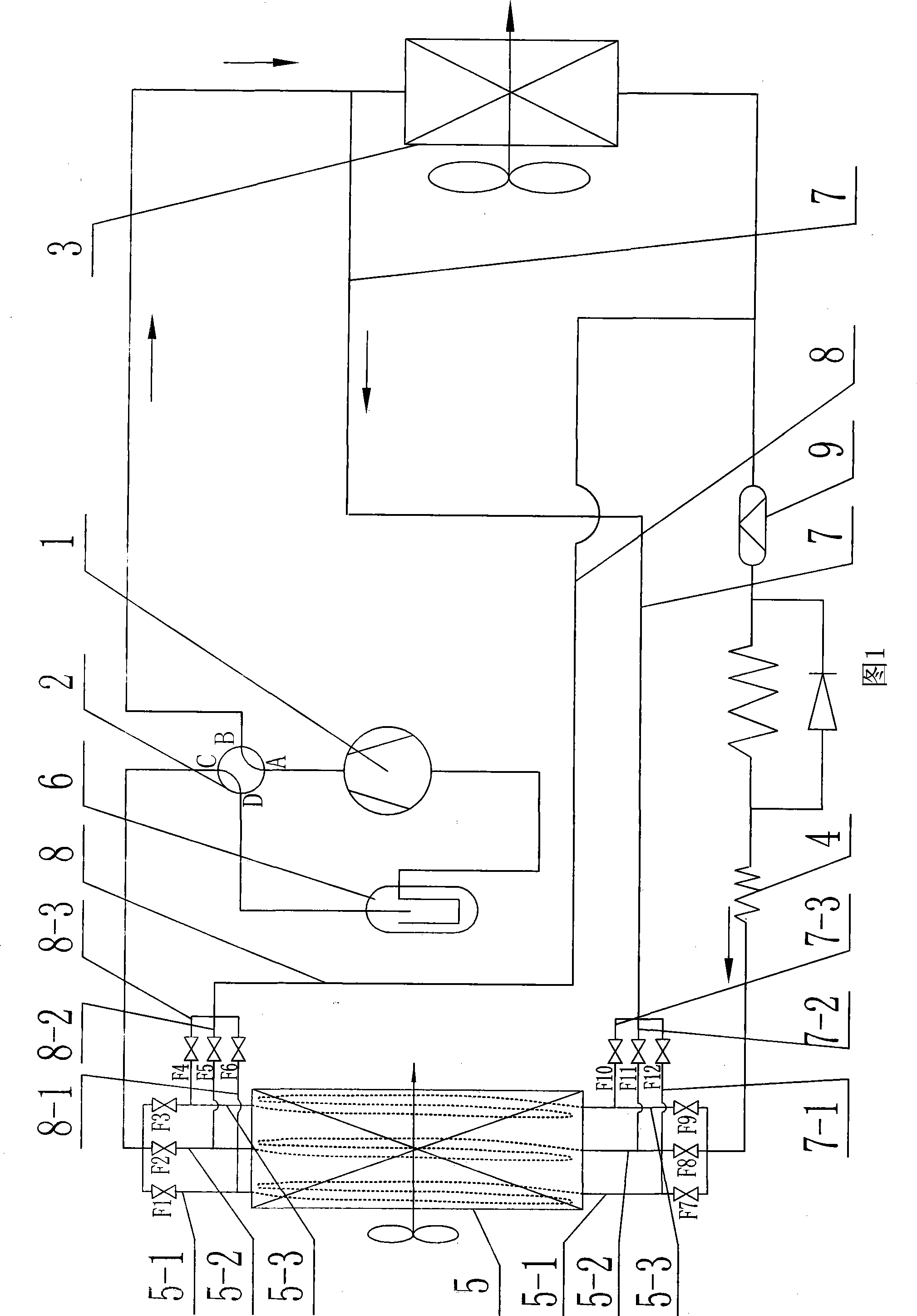

[0007] Specific Embodiment 1: As shown in Figure 1, the air source heat pump system described in this embodiment that can supply heat intermittently under defrosting conditions includes a compressor 1, a four-way reversing valve 2, an indoor unit 3, a throttling Mechanism 4, outdoor unit 5 and gas-liquid separator 6, the air source heat pump system also includes a first solenoid valve F1, a second solenoid valve F2, a third solenoid valve F3, a seventh solenoid valve F7, an eighth solenoid valve F8, The ninth solenoid valve F9, the defrosting branch assembly and the step-down branch assembly; the defrosting branch assembly consists of the tenth solenoid valve F10, the eleventh solenoid valve F11, the twelfth solenoid valve F12, the defrosting branch Road 7, the first defrosting branch road 7-1, the second defrosting branch road 7-2 and the third defrosting branch road 7-3, the step-down branch circuit assembly is composed of the fourth solenoid valve F4, the fifth solenoid valv...

specific Embodiment approach 2

[0009] Embodiment 2: As shown in FIG. 1 , the air source heat pump system in this embodiment further includes a dryer 9 , and the dryer 9 is arranged on the pipeline between the indoor unit 3 and the throttling mechanism 4 . The drier 9 can remove substances such as moisture in the refrigerant. Other components and connections are the same as those in the first embodiment.

[0010] working principle:

[0011] When the present invention is in the heating state, the fourth solenoid valve F4, the fifth solenoid valve F5, the sixth solenoid valve F6, the tenth solenoid valve F10, the eleventh solenoid valve F11 and the twelfth solenoid valve F12 are all kept closed, and the The first solenoid valve F1, the second solenoid valve F2, the third solenoid valve F3, the seventh solenoid valve F7, the eighth solenoid valve F8 and the ninth solenoid valve F9 are kept open. The high-temperature (high-pressure) gas refrigerant discharged from the compressor 1 is turned into a low-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com