An AC plasma-oxygen-enriched ignition burner

A kind of ignition burner and burner technology, applied in the direction of burner, gas fuel burner, combustion type, etc., can solve the problem of poor adaptability of coal types, etc., and achieve the effect of prolonging the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

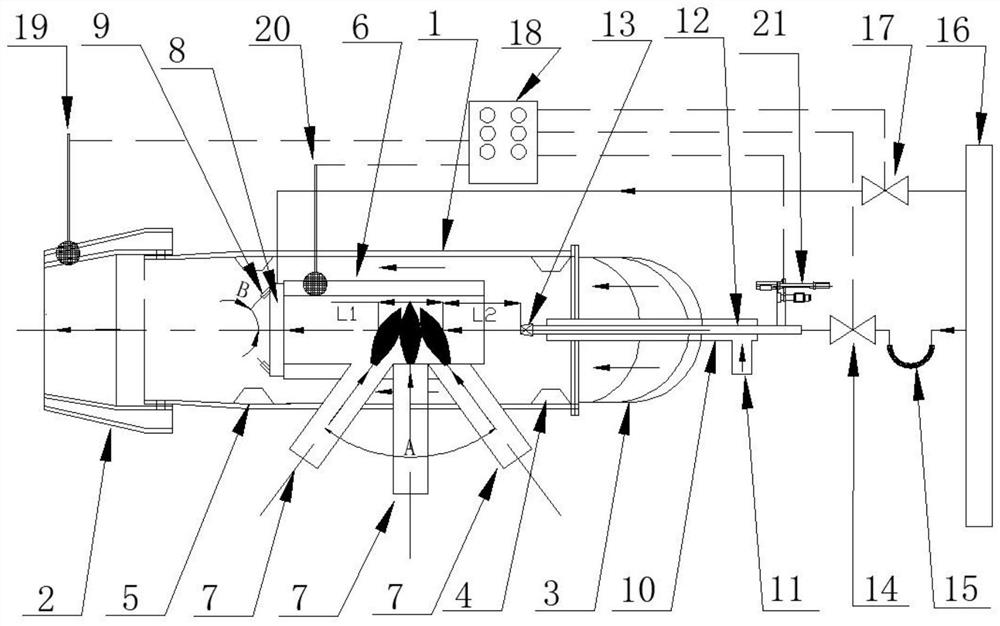

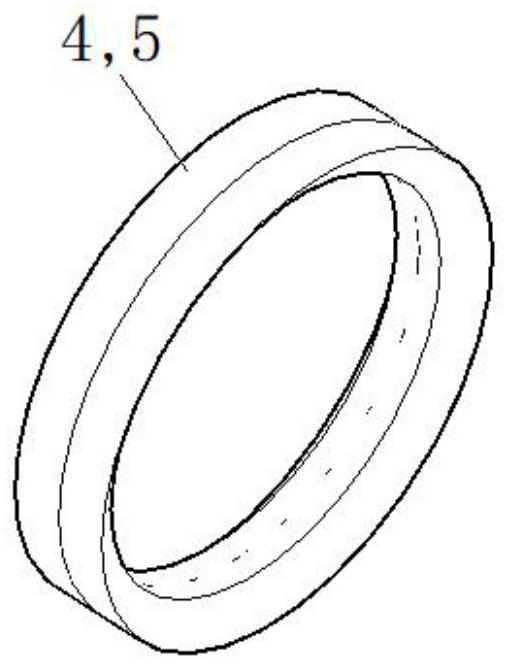

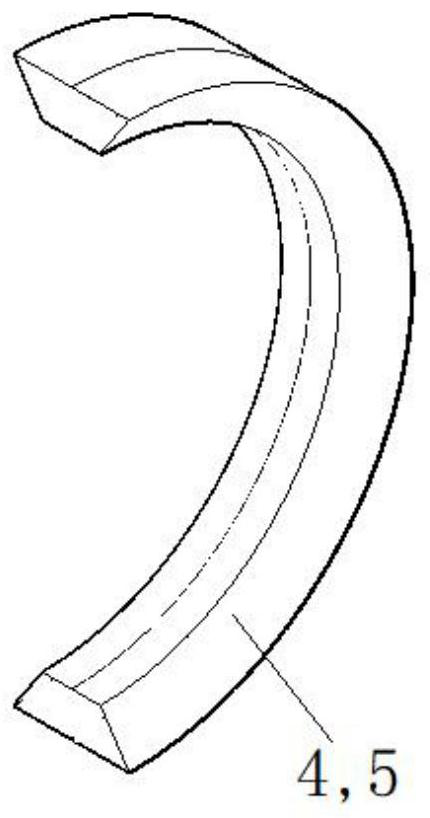

[0027] Such as Figure 1-5 As shown, an AC plasma-oxygen-enriched ignition burner in this embodiment includes a burner body 1, a nozzle 2 is provided at the left end of the burner body 1, and a nozzle 2 passes through the right end of the burner body 1. The flange is fixedly connected with a pulverized coal elbow 3, and a center cylinder 6 is provided inside the burner body 1 at the central axis of the burner body 1, and a center cylinder 6 is provided on the inner wall of the right end and the left end of the burner body 1 respectively. Level concentration ring 4 and secondary concentration ring 5, and make secondary concentration ring 5 be positioned at the exit of central tube 6, be provided with three alternating current plasma generators 7 on the outer wall of central tube 6, described alternating current plasma generator 7 on both sides The included angle of the axis of the generator 7 is 50°, so that the plasma arcs of the three AC plasma generators 7 converge at the ce...

Embodiment 2

[0030] Such as Figure 1-4 As shown, an AC plasma-oxygen-enriched ignition burner in this embodiment includes a burner body 1, a nozzle 2 is provided at the left end of the burner body 1, and a nozzle 2 passes through the right end of the burner body 1. The flange is fixedly connected with a pulverized coal elbow 3, and a center cylinder 6 is provided inside the burner body 1 at the central axis of the burner body 1, and a center cylinder 6 is provided on the inner wall of the right end and the left end of the burner body 1 respectively. Level concentration ring 4 and secondary concentration ring 5, and make secondary concentration ring 5 be positioned at the exit of central tube 6, be provided with three alternating current plasma generators 7 on the outer wall of central tube 6, described alternating current plasma generator 7 on both sides The included angle of the axis of the generator 7 is 80°, so that the plasma arcs of the three AC plasma generators 7 converge at the ce...

Embodiment 3

[0033] Such as Figure 1-4 As shown, an AC plasma-oxygen-enriched ignition burner in this embodiment includes a burner body 1, a nozzle 2 is provided at the left end of the burner body 1, and a nozzle 2 passes through the right end of the burner body 1. The flange is fixedly connected with a pulverized coal elbow 3, and a center cylinder 6 is provided inside the burner body 1 at the central axis of the burner body 1, and a center cylinder 6 is provided on the inner wall of the right end and the left end of the burner body 1 respectively. Level concentration ring 4 and secondary concentration ring 5, and make secondary concentration ring 5 be positioned at the exit of central tube 6, be provided with three alternating current plasma generators 7 on the outer wall of central tube 6, described alternating current plasma generator 7 on both sides The included angle of the axis of the generator 7 is 60°, so that the plasma arcs of the three AC plasma generators 7 converge at the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com