Air conditioner system and defrosting method thereof

A technology for air conditioners and outdoor heat exchangers, applied in air conditioning systems, heating methods, space heating and ventilation, etc., can solve problems such as exhaust temperature drop, long defrosting time, outdoor unit vibration, etc., to achieve sufficient heat supply , Short defrosting time, quick defrosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

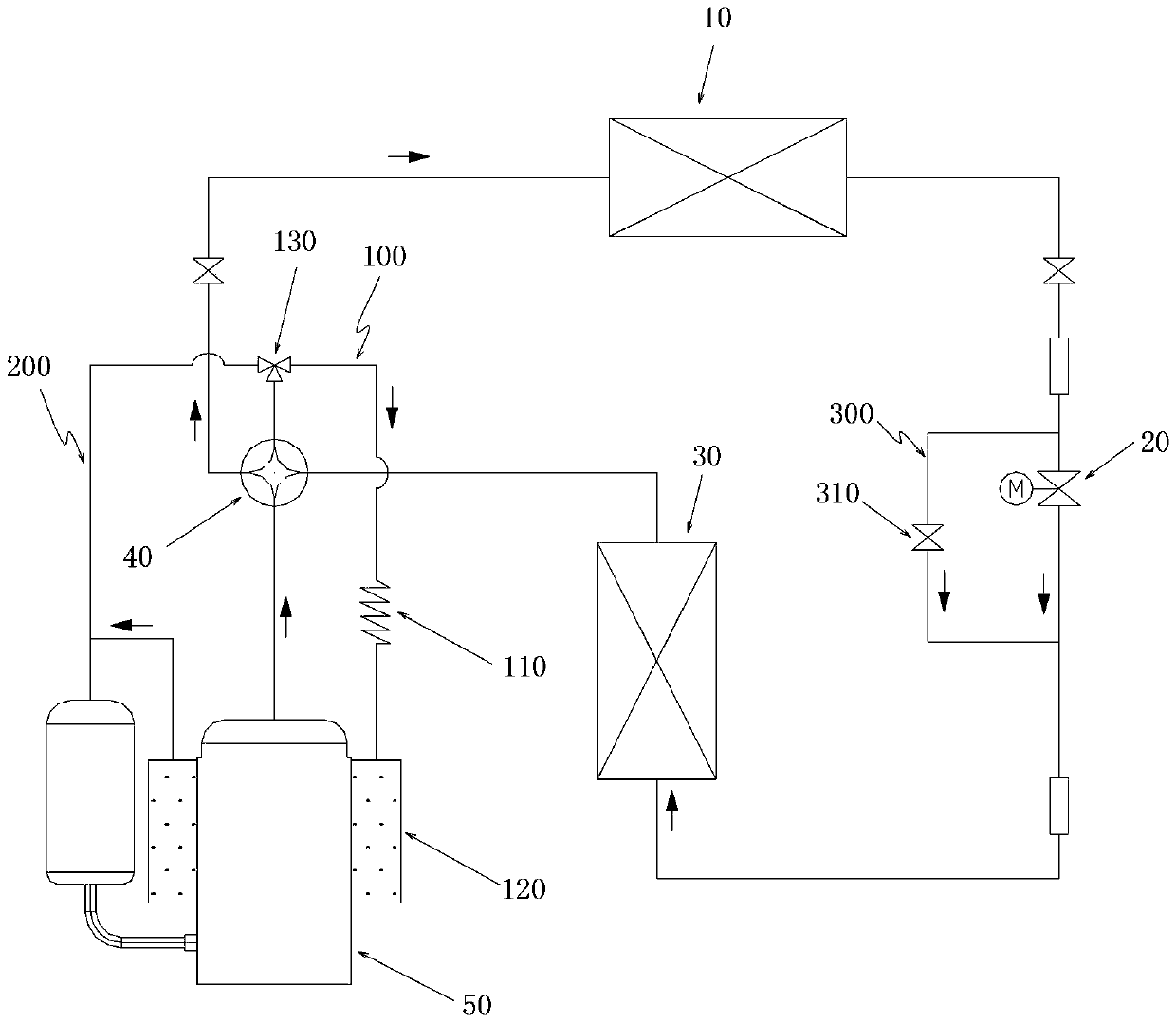

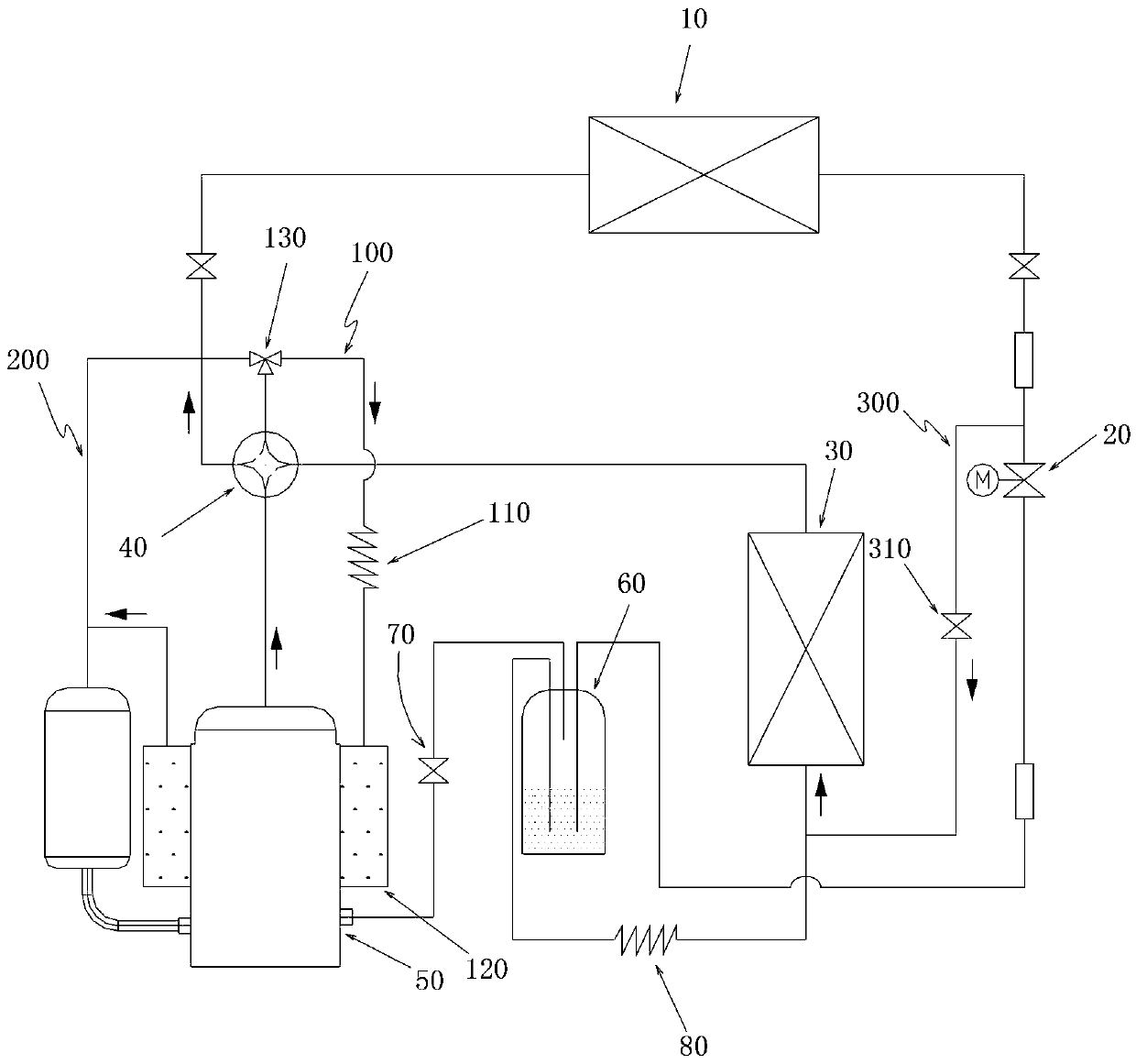

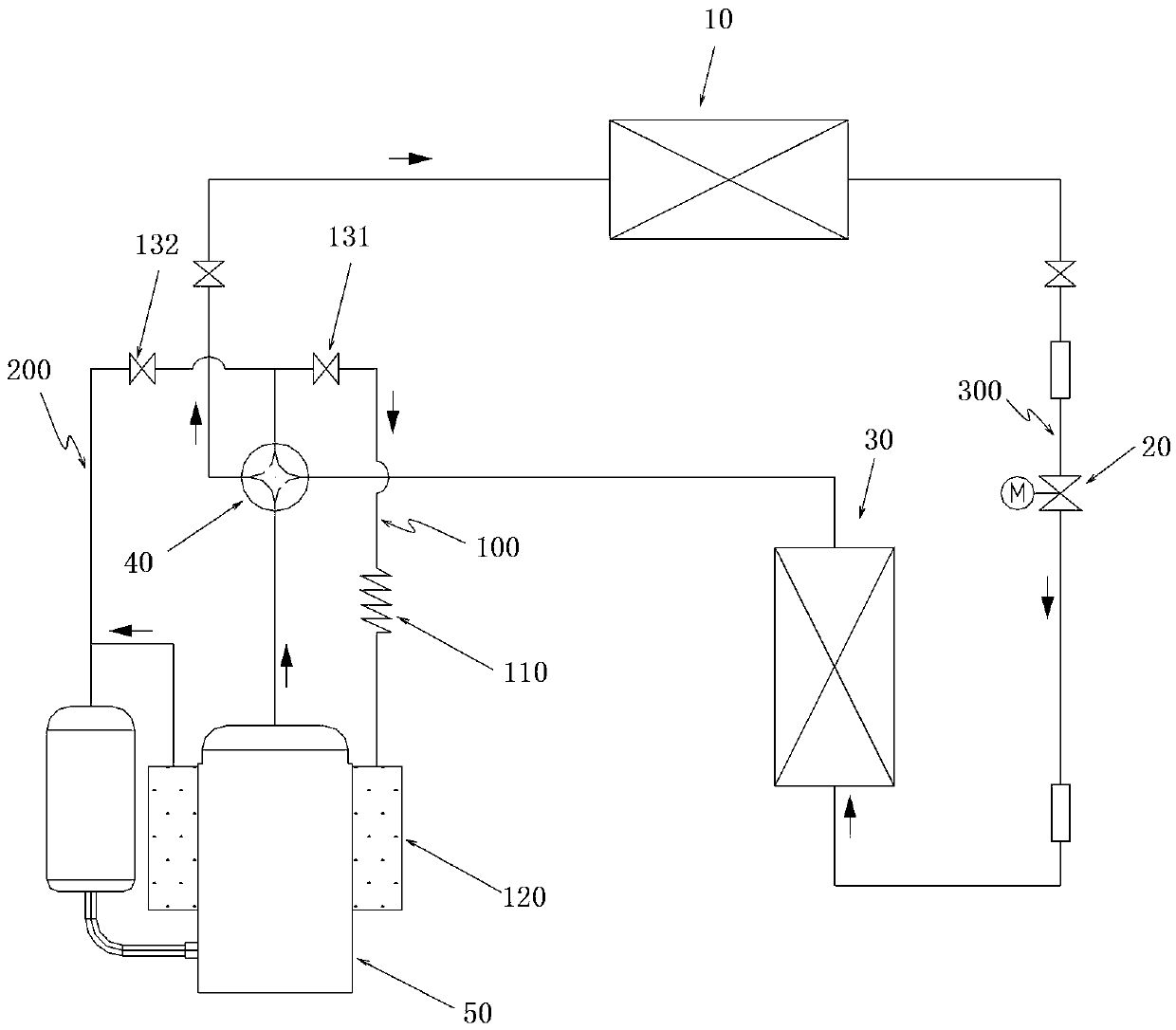

[0041] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0042] The invention provides a defrosting method for an air conditioner system, wherein, when the outdoor heat exchanger is defrosted, the refrigerant flowing out of the indoor heat exchanger enters the outdoor heat exchanger in the form of hot liquid (that is, without throttling) to Achieving hot liquid defrosting.

[0043] The advantages of the above defrosting method are as follows: 1. Using hot liquid defrosting technology, the heat supply is sufficient, and the defrosting is extremely fast; 2. The non-stop defrosting is realized, and the defrosting time is short. Great contribution to comfort.

[0044] Preferably, the refrigerant at the outlet of the outdoor heat exchanger is throttled through the capillary tube, then enters the heat accumula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com