A thermal chemical adsorption heat storage system for building heating

A heat storage system and thermochemical technology, applied in the field of building heating, can solve the problems of poor thermal comfort, decreased heating performance, environmental and people's health hazards, and solve the problem of energy supply and demand imbalance, low processing costs and operating costs. , the effect of alleviating grid pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

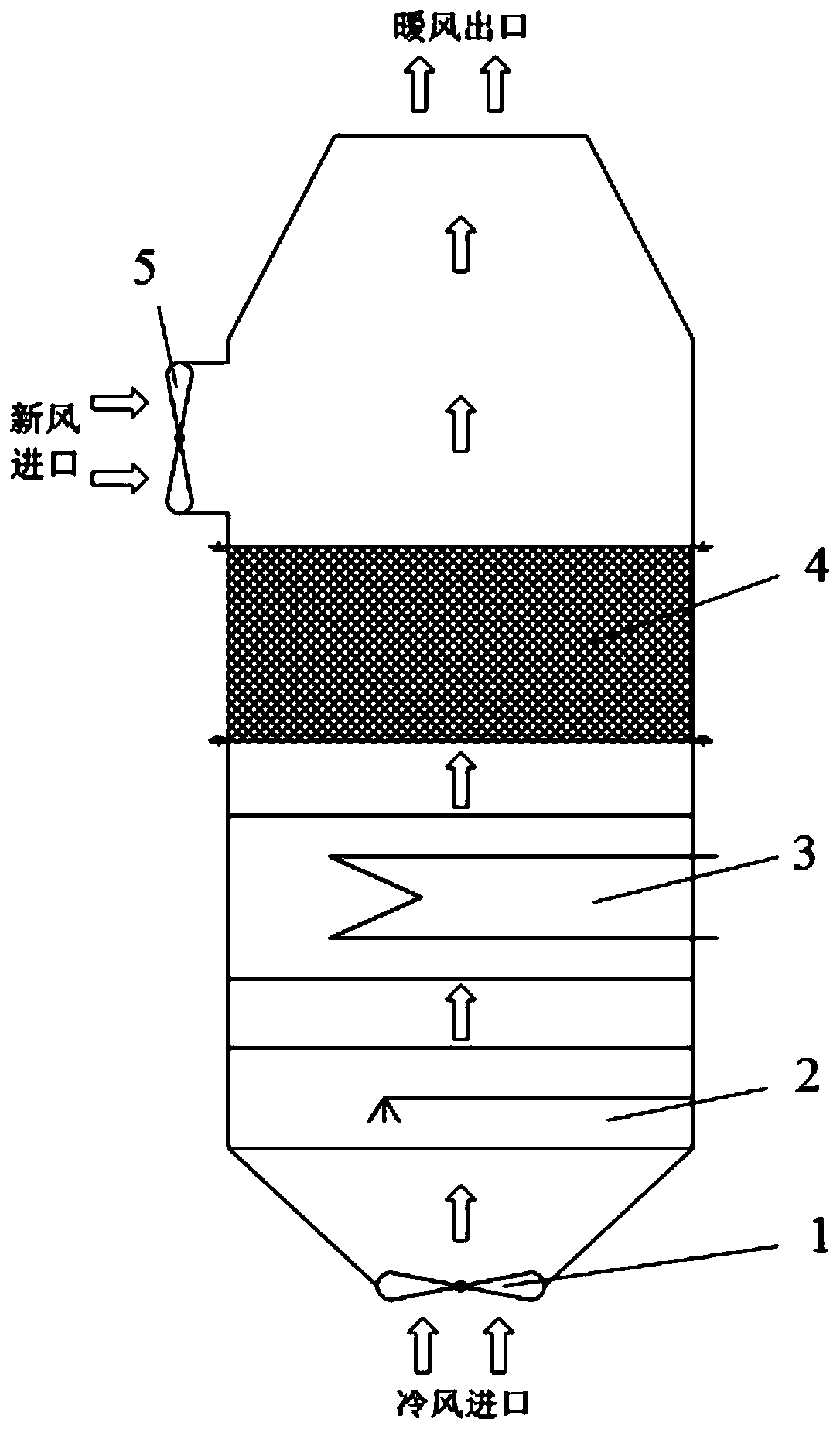

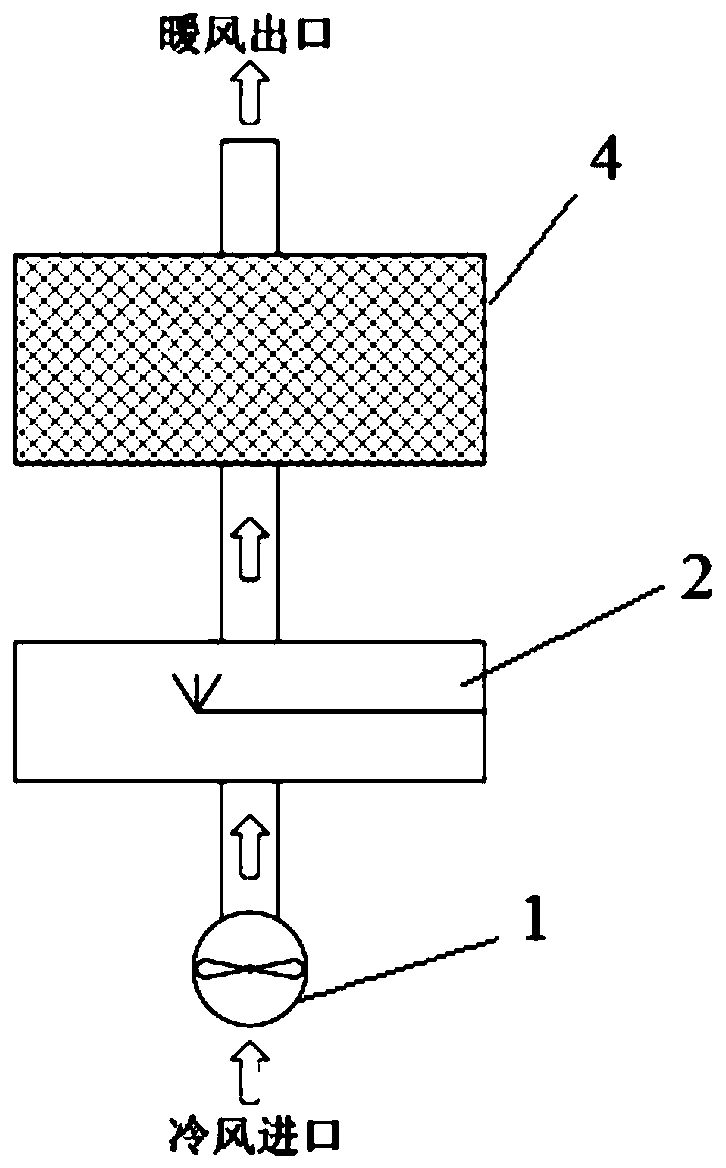

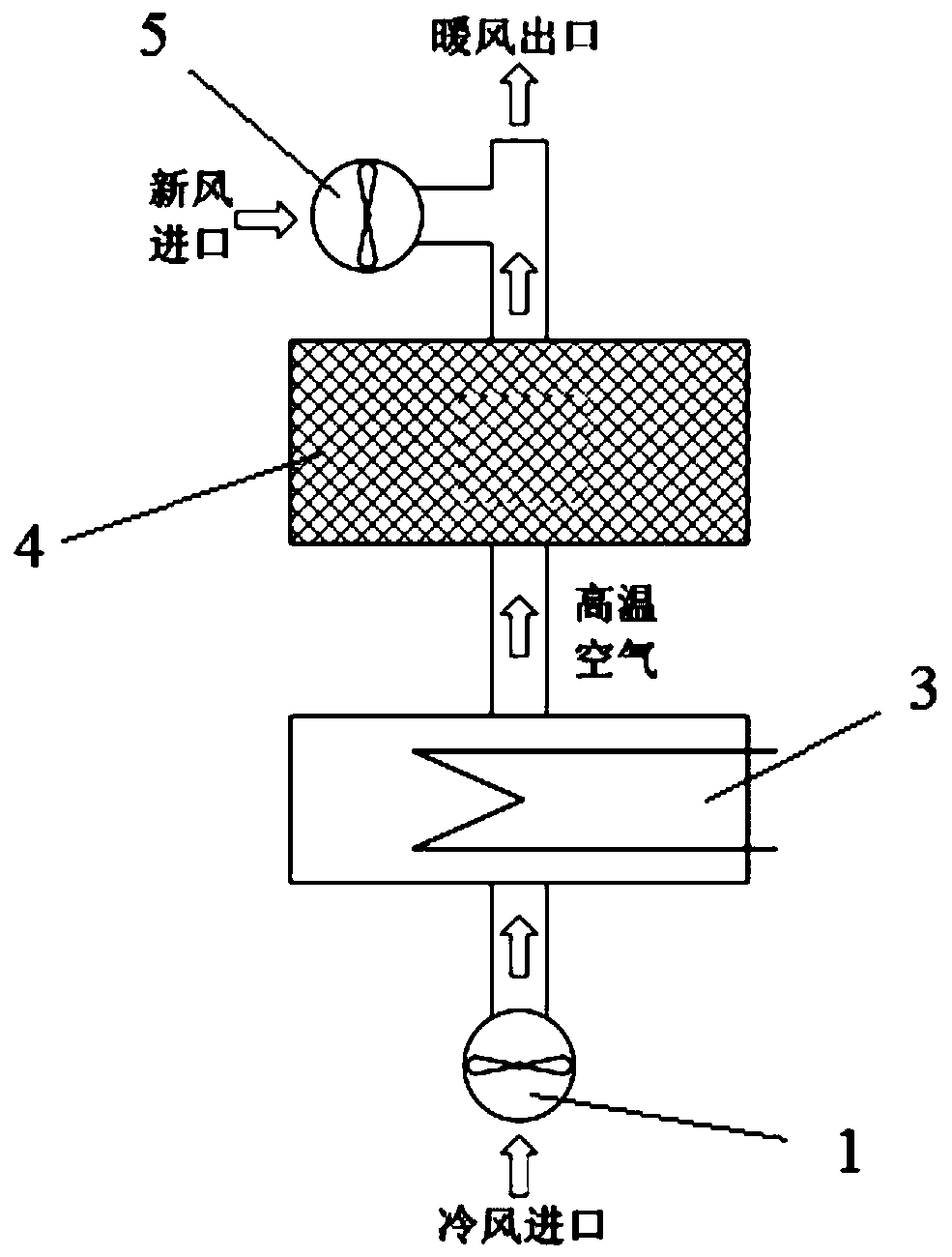

[0031] A thermal chemical adsorption heat storage system for building heating, its structure is as follows figure 1 Shown, comprise air channel, and the cold air fan 1 that is arranged in the air channel along the cold air flow direction and the adsorption bed 4 that built-in has the adsorbent of water absorption and heat storage capacity, also between cold air fan 1 and adsorption bed 4 A humidifier 2 and a heater 3 are arranged, and a fresh air inlet with a fresh air blower 5 is arranged on the air channel at the rear end of the adsorption bed 4 .

[0032] As a preferred embodiment of the present invention, the adsorption bed 4 is composed of a plurality of four-layer units of the adsorption bed, and the adsorbent is built in the four-layer unit of the adsorption bed. More preferably, the four-layer units of the adsorption bed are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com