Hot water manufacturing method of air heat source and exhaust steam residual heat complementary

A manufacturing method, air source heat pump technology, applied in the direction of heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of waste of heat energy and high-temperature condensed water, save electric energy, save water resources, and improve capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Laundry rooms of star-rated hotels or guesthouses have a lot of clothes, bed sheets, and quilt covers to be washed with hot water for a long time and baked with steam. Dirty hot water after washing and exhausted steam after baking are usually directly discharged into the laundry room. In the trench inside the laundry room, the environment in the laundry room is humid and hot, which seriously corrodes the equipment and is unfavorable to the physical and mental health of employees; especially in summer, the temperature in the laundry room is as high as 40-50°C. On the one hand, the effect is not very good due to too much humidity.

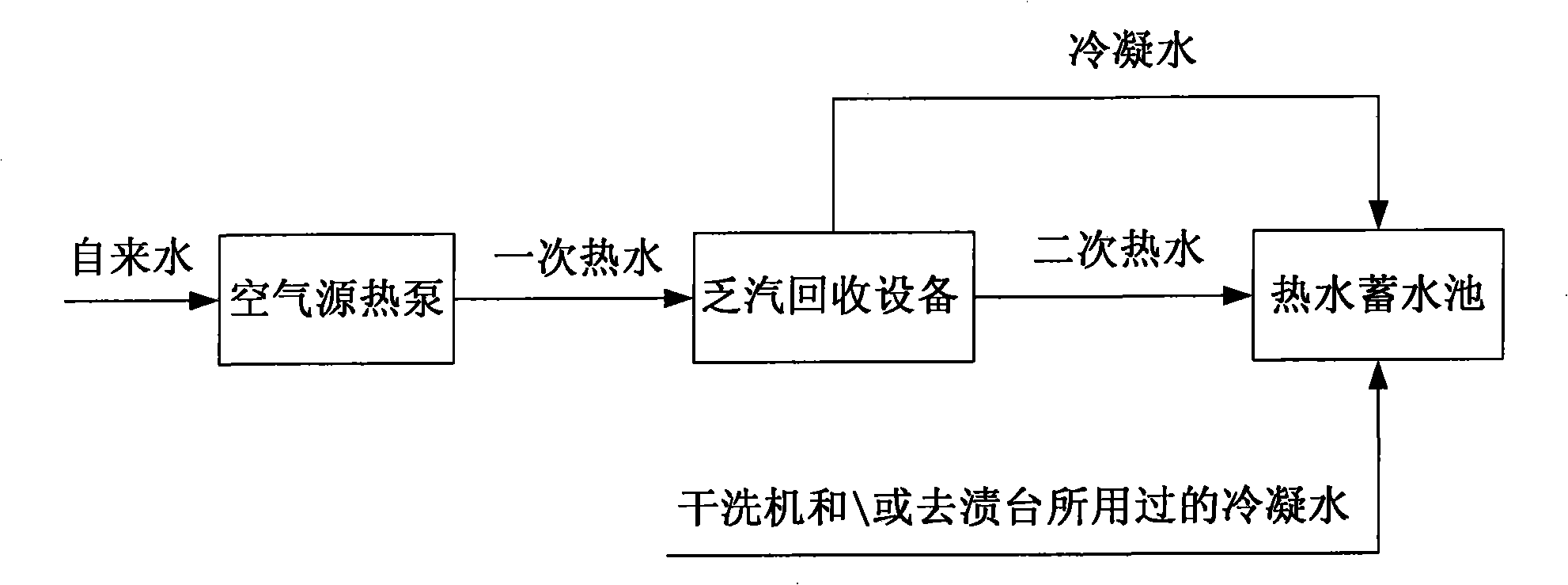

[0022] Such as figure 1 As shown, the air source heat pump is installed in the laundry room, and the cold air absorbed by the heat pump is directly discharged into the laundry room from April to October every year to reduce the ambient temperature in the laundry room; every year from November to the next year In March, the cold air is dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com