Butt welding method of small caliber metallic resistances

A metal resistance and small-diameter technology, which is applied in resistance welding equipment, metal processing equipment, welding equipment, etc., can solve the problem that the welding shrinkage cannot be guaranteed, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

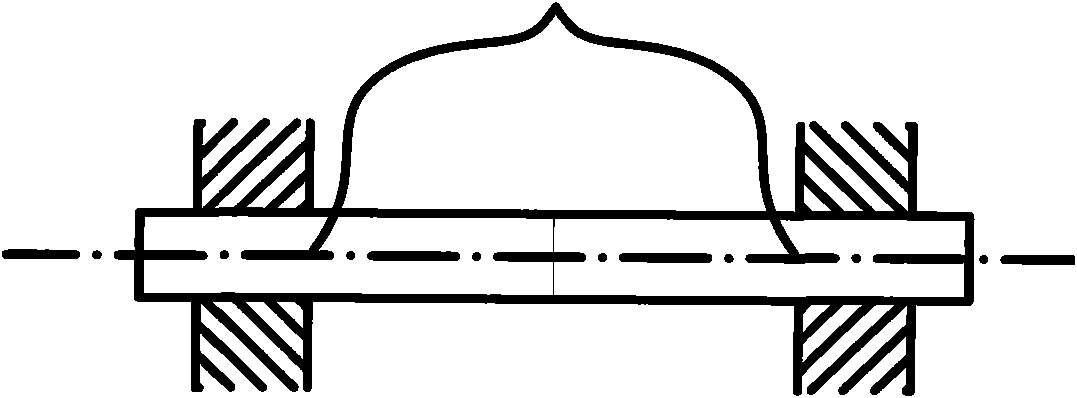

[0029] The present invention will be further described below in conjunction with accompanying drawing:

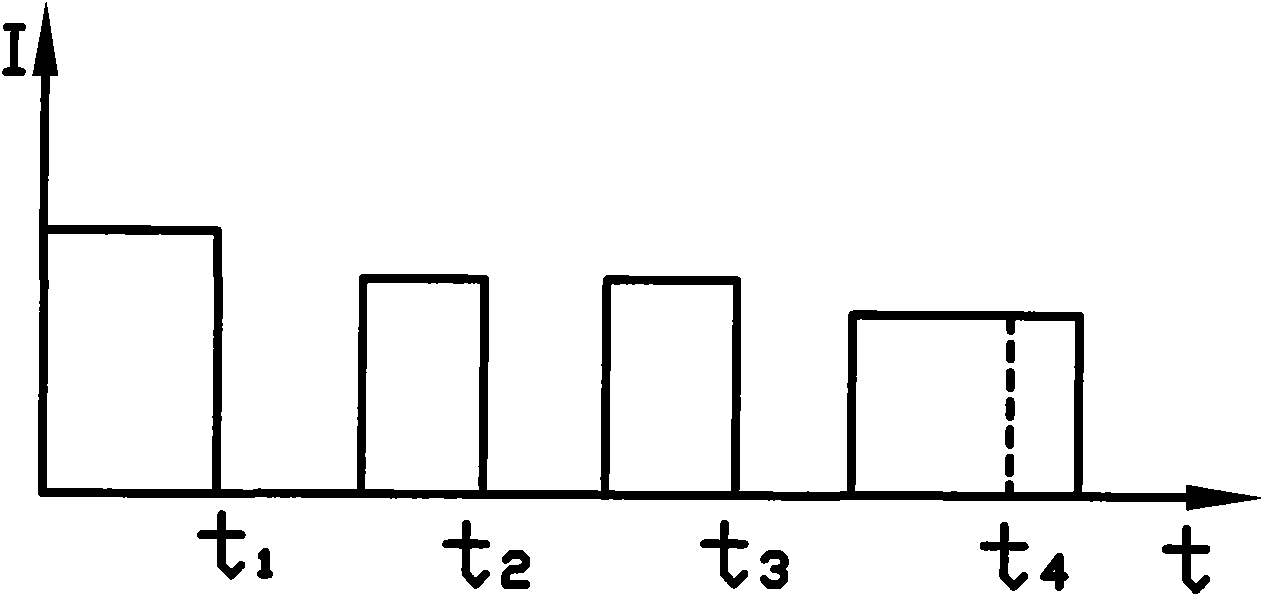

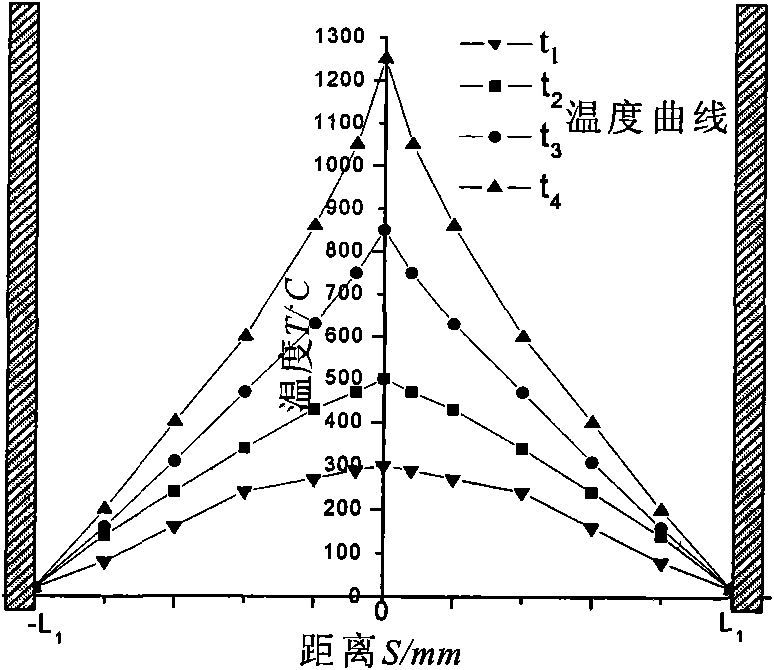

[0030] The present invention adopts multiple intermittent power-on heating and continuous uneven heat dissipation to establish a suitable welding temperature field. Generally, the times of power-on and power-off are 1 to 5 times. Generally, different energization time (generally 10-2000ms) and different energization current (generally 100-5000A) are selected each time according to the actual welding needs. After the first power-on heating is completed, select the power-off time (generally 10-2000ms) according to the needs. After the first power-off time is over, the second power-on heating is performed, and so on. Under the action of upsetting pressure, the bond between atoms is formed, so as to obtain a strong joint.

[0031] In this embodiment, the temperature of the welding tongs is guaranteed to be constant at room temperature through two methods of relatively large h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com