Double wheel normal rotor engine

A rotary engine and engine technology, applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as increased wear, high cost, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

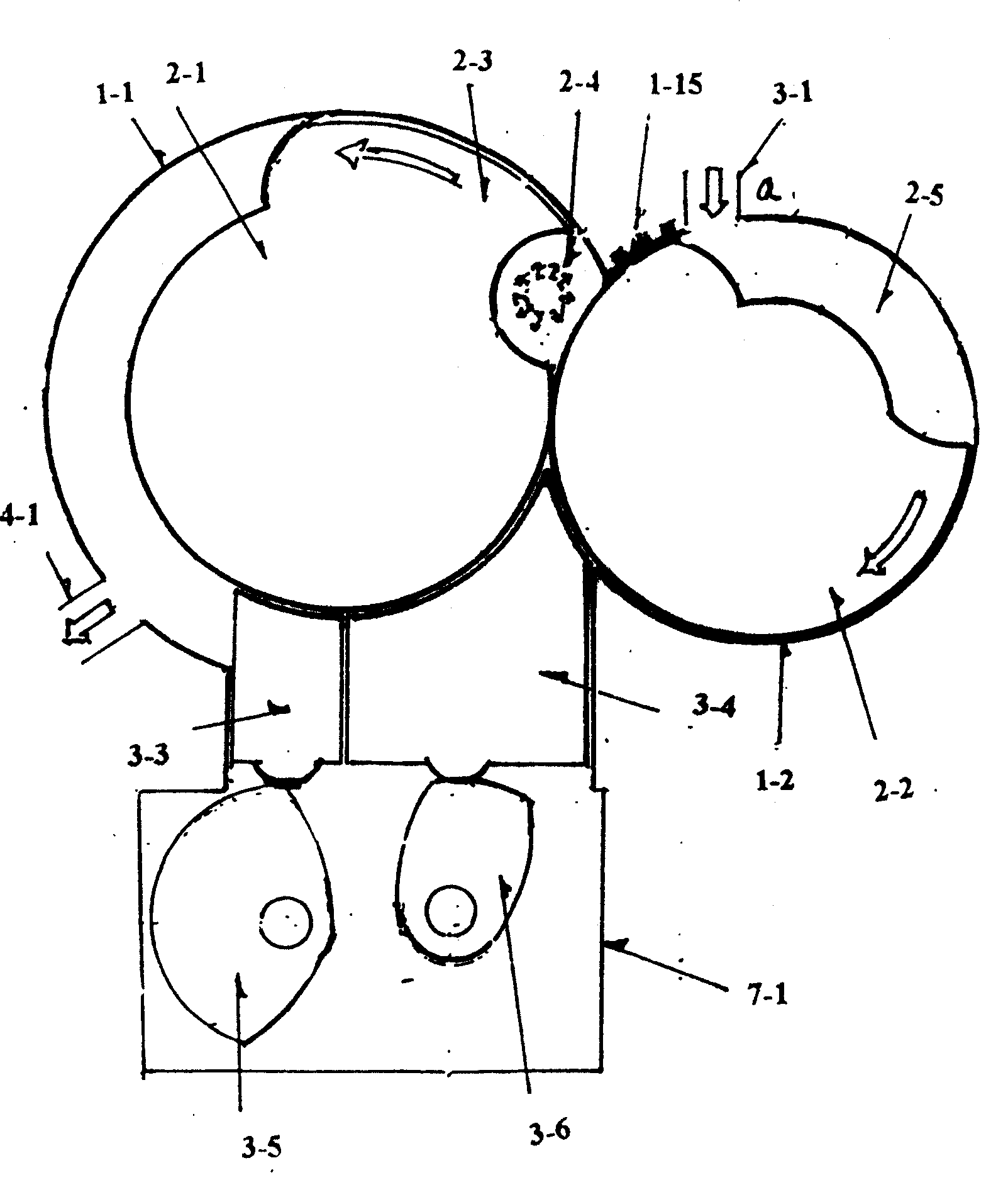

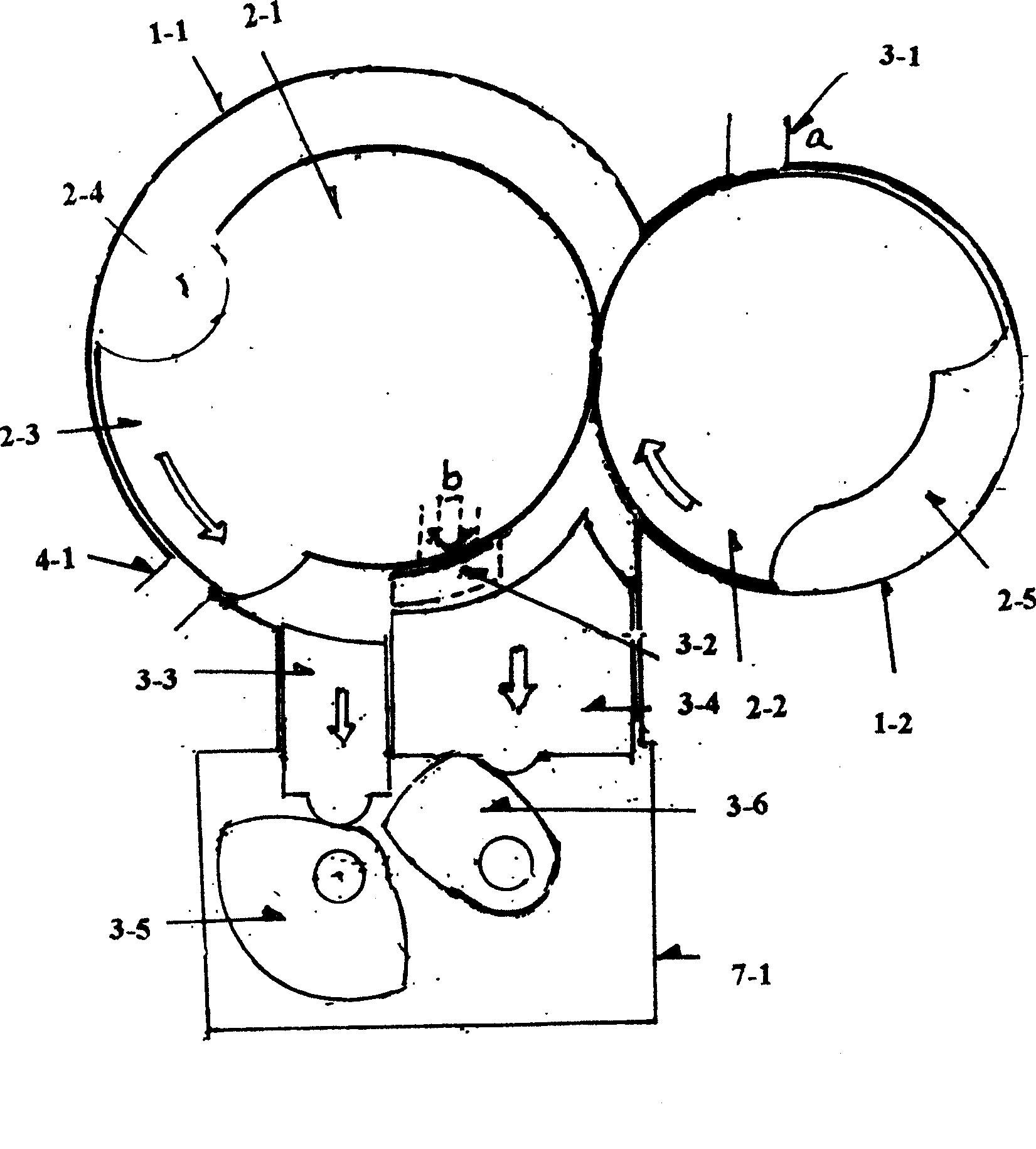

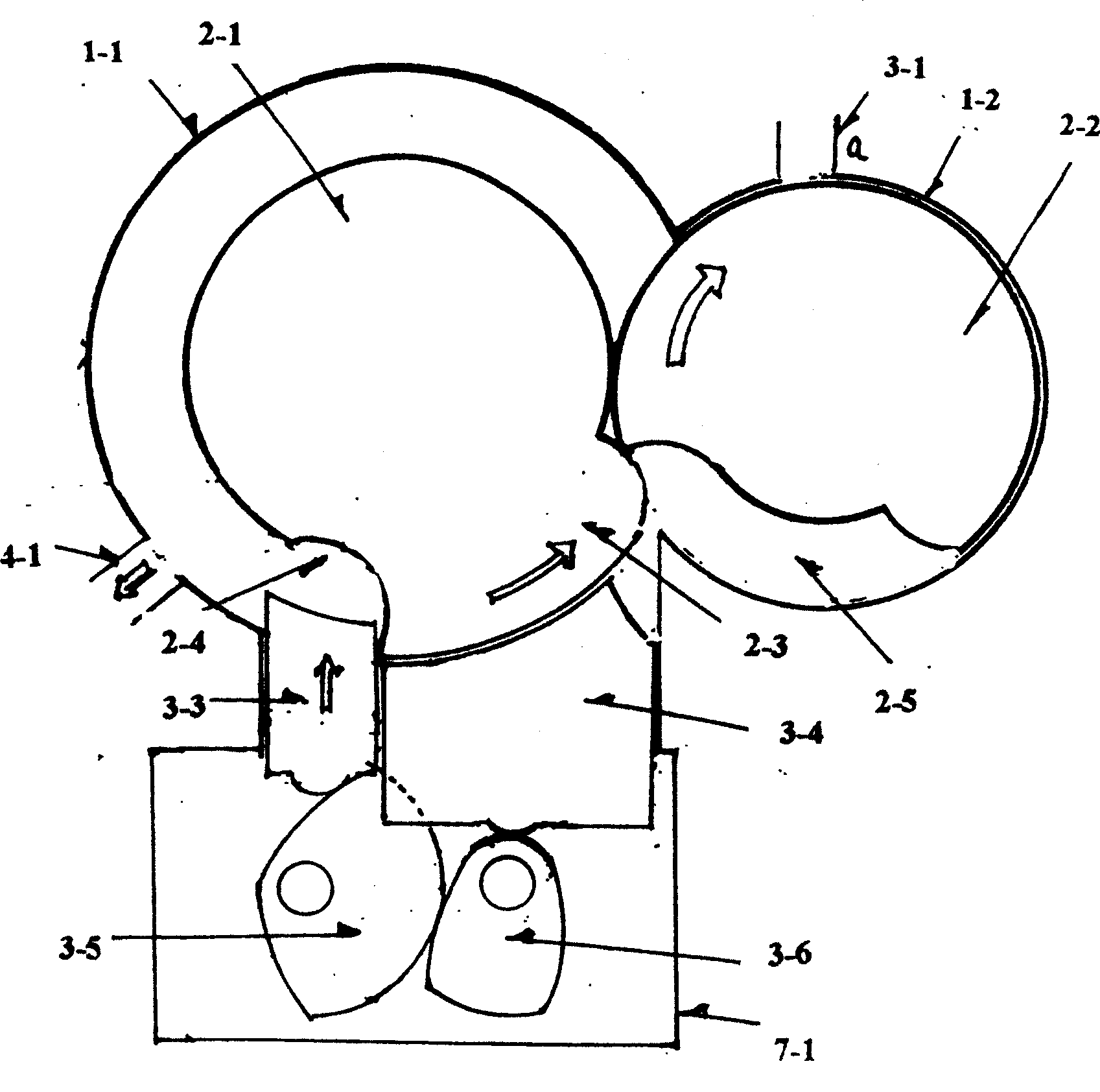

[0048] Such as figure 1 Shown: This is the structural diagram of the first section of the engine working principle. Wherein, some components are the same as those of the prior art, and some components need to be further described in the accompanying drawings. The first stage of the working principle of this engine is combustion explosion, when the main wheel 2-3 above the main wheel 2-1 rotates to the upper position, the fresh air in the compression chamber 2-4 has been compressed, and it acts as a combustion chamber The beginning part is ignited by the spark plug. Since the shape of the combustion chamber is close to a cylinder, the way the fresh air inside is pressed in is to generate a swirl flow along the cylinder space, which creates good conditions for the propagation and dispersion of the combustion flame. The condition of the compression chamber in the prior art, especially the shape condition of the compression chamber of the triangular rotor engine which is also the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com