Low-carbon deep-desulfurization refining method of LF (ladle refining) furnace

A deep desulfurization and slag technology, applied in the field of steelmaking, can solve the problems of adverse effects of molten steel quality and production efficiency, unstable sulfur content at the end of treatment, increased equipment investment, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

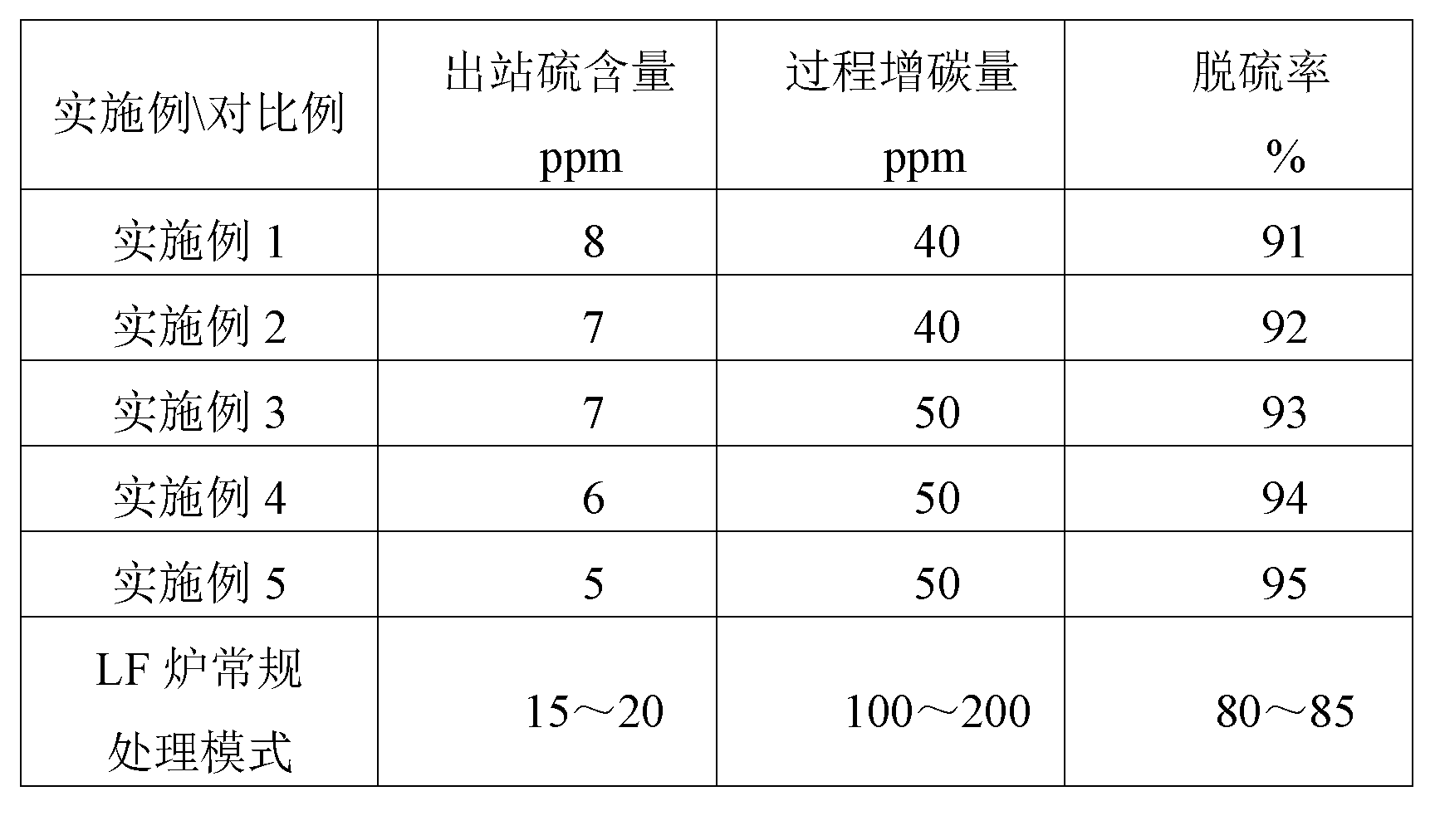

Examples

Embodiment 1

[0032] The initial carbon and sulfur content of molten steel entering the LF furnace: C: 0.045%, S: 0.0086%.

[0033] 1) Enter the station to raise the temperature of the slag: After the molten steel enters the LF furnace station, turn on the argon gas to break the slag, the argon gas flow rate is 750NL / min (the argon flower in the slag layer on the molten steel surface is in the range of 300-400mm by visual inspection), and feed the Al wire to the Alt % adjusted to 0.065%. And add lime at one time, the amount of lime is 15Kg / t steel, the amount of fluorite is 2.5Kg / t steel, argon flow is adjusted to 200NL / min after stirring with a large amount of argon until the lime is molten Spend in the range of 150-200mm), power transmission to raise temperature for 11 minutes, keep argon flow at 200NL / min during power transmission, according to the slag condition, aluminum shot 0.2Kg / t steel and fluorite 0.2Kg / t steel can be added to adjust the slag. Before the end of the first power tr...

Embodiment 2

[0040] The initial carbon and sulfur content of molten steel entering the LF furnace: C: 0.046%, S: 0.0089%.

[0041] 1) Entering the station to raise the temperature of the slag: After the molten steel enters the LF furnace station, turn on the argon gas to break the slag, the argon gas flow rate is 770NL / min (the argon flower on the slag layer on the molten steel surface is in the range of 300-400mm by visual inspection), feed the Al wire to the Alt % adjusted to 0.068%. And add lime at one time, the amount of lime is 17Kg / t steel, the amount of fluorite is 2.8Kg / t steel, argon flow is adjusted to 220NL / min after stirring with a large amount of argon until the lime is molten Spend in the range of 150-200mm), power transmission to raise the temperature for 12min, keep the argon flow at 220NL / min during power transmission (visual inspection of the slag layer of the molten steel surface in the range of 150-200mm), and add 0.27Kg of aluminum shot according to the slag condition ...

Embodiment 3

[0048] The initial carbon and sulfur content of molten steel entering the LF furnace: C: 0.047%, S: 0.0094%.

[0049] 1) Entering the station to raise the temperature of the slag: After the molten steel enters the LF furnace station, turn on the argon gas to break the slag, the flow rate of the argon gas is 800NL / min (the argon flower in the slag layer on the molten steel surface is in the range of 300-400mm by visual inspection), and feed the Al wire to the Alt % adjusted to 0.070%. And add lime at one time, the amount of lime is 18Kg / t steel, the amount of fluorite is 3Kg / t steel, and the argon flow is adjusted to 230NL / min after stirring with a large amount of argon until the lime is in a molten state (visual inspection In the range of 150-200mm), the temperature is raised by power transmission for 13 minutes, and the flow rate of argon gas is kept at 230NL / min during the power transmission process (the argon flower of the slag layer on the molten steel surface is in the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com